Movement guiding device, table device, and damping method for movement guiding device

A guide device and workbench technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., to achieve the effects of low load, improved oil retention characteristics, and small braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0111] Mathematical formula 1 below shows the formula for calculating the viscous resistance of oil. FIG. 22 is a schematic diagram showing parameters used in this calculation formula.

[0112] [number 1]

[0113] γ(1 / s)=V(m / s) / h(m)

[0114] τ(Pa)=F(N) / A(m 2 )

[0115] η(Pa·s)=τ(Pa) / γ(1 / s)

[0116] ε(mm 2 / s)=η(Pa·s) / 10 3 / ρ(g / cm 3 )

[0117] thus

[0118] F(N)=η(Pa·s)·A(m 2 )·V(m / s) / h(m)

[0119] =ε(mm 2 / s)·ρ(g / cm3)·A(m 2 )·V(m / s)·10 3 / h(m)

[0120] γ: cutting speed

[0121] V: speed

[0122] h: height

[0123] τ: shear stress

[0124] F: Viscous resistance

[0125] A: contact area

[0126] η: Viscosity

[0127] ε: dynamic viscosity

[0128] ρ: density

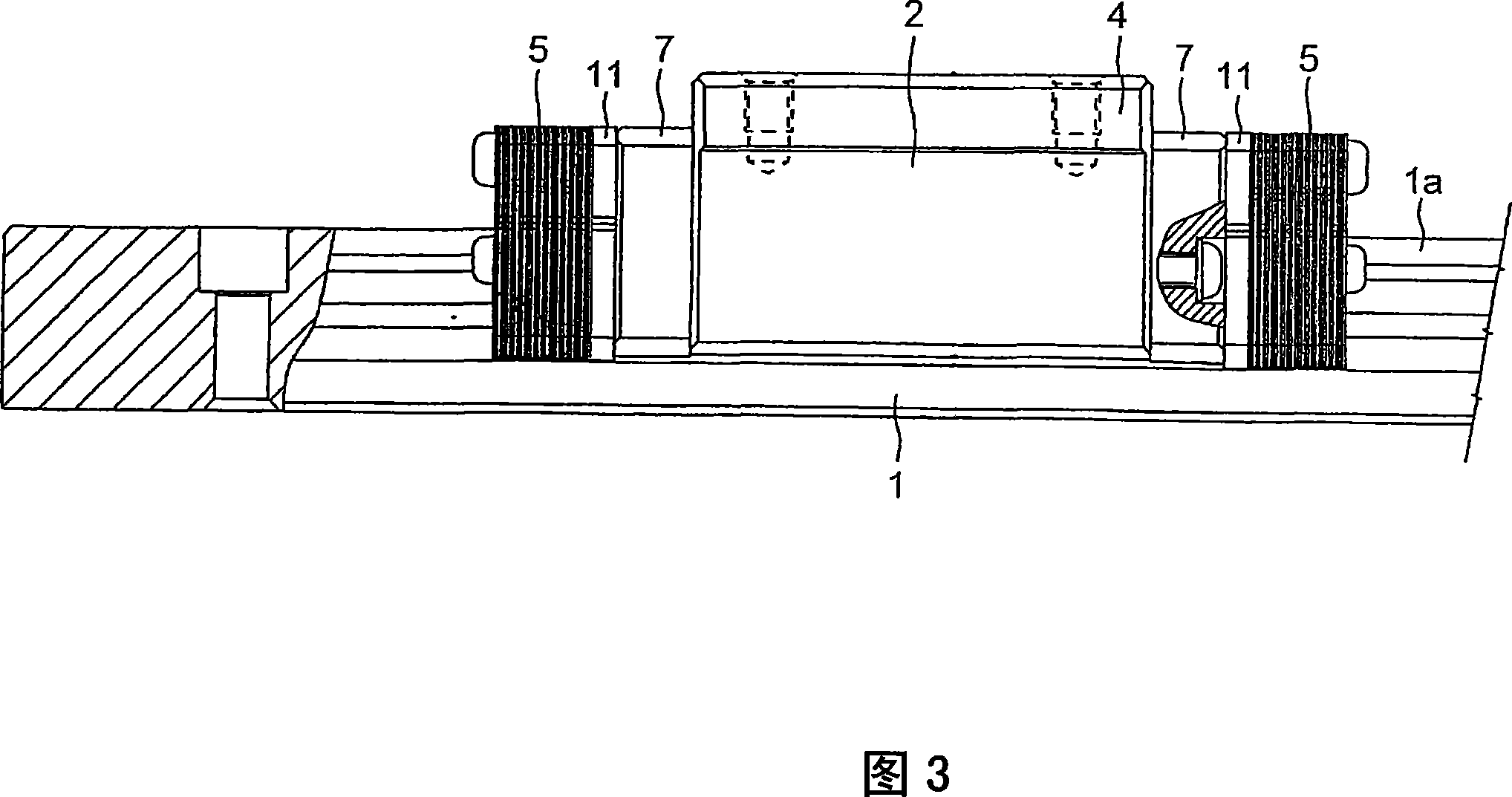

[0129] One parameter of the viscous resistance F is the velocity V. The faster the moving part 2 moves, the greater the viscous resistance F. The height h is the height of the oil layer, that is, the size of the gap 16 between the end damping part 5 and the track guide rail 1 . The narrower the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com