Air suspension vehicle load sensing valve system and control method thereof

A technology of air suspension and load-sensing valves, which is applied to vehicle components, control valves, air release valves, brakes, etc., can solve the problems of low safety, achieve high safety, easy operation, and ensure driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

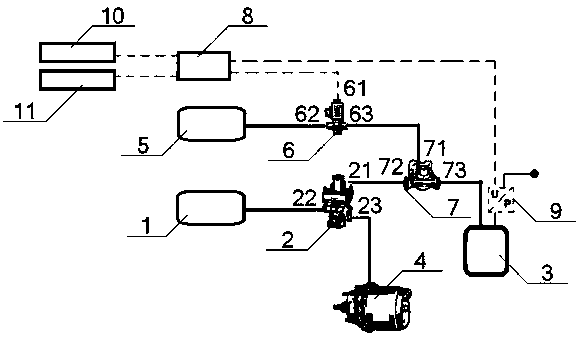

[0033] see figure 1, an air suspension vehicle load sensing valve system, comprising an air storage tank 1, a load sensing valve 2, a suspension air bag 3, a brake chamber 4, an auxiliary air storage tank 5, a solenoid valve 6, a two-way valve 7, a controller 8, Air pressure sensor 9, brake signal 10, vehicle speed signal 11, the load sensing valve 2 includes a control port 21, the load sensing valve inlet 22, and the load sensing valve air outlet 23, and the air storage tank 1 enters through the load sensing valve in turn. The gas port 22 and the load-sensing valve gas outlet 23 communicate with the brake chamber 4 behind. The solenoid valve 6 includes a coil 61, a solenoid valve inlet 62, and a solenoid valve gas outlet 63. The two-way valve 7 includes a two-way valve. No. 7 air inlet 71, the No. 2 air inlet 73 of the two-way valve, and the No. 1 air outlet 72 of the two-way valve. , the two-way valve air outlet 72 communicates with the control port 21, and the suspension a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com