A continuous production line for multi-brewed small pots of tea

A production line and canned tea technology, applied in packaging, packaging machines, packaging sterilization and other directions, can solve the problems of the inability to guarantee the nitrogen filling of the tea canning production line, the short shelf life of tea and tea, and the easy pollution of tea packaging materials, so as to overcome the technical problems. Obstacle, stable quality, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

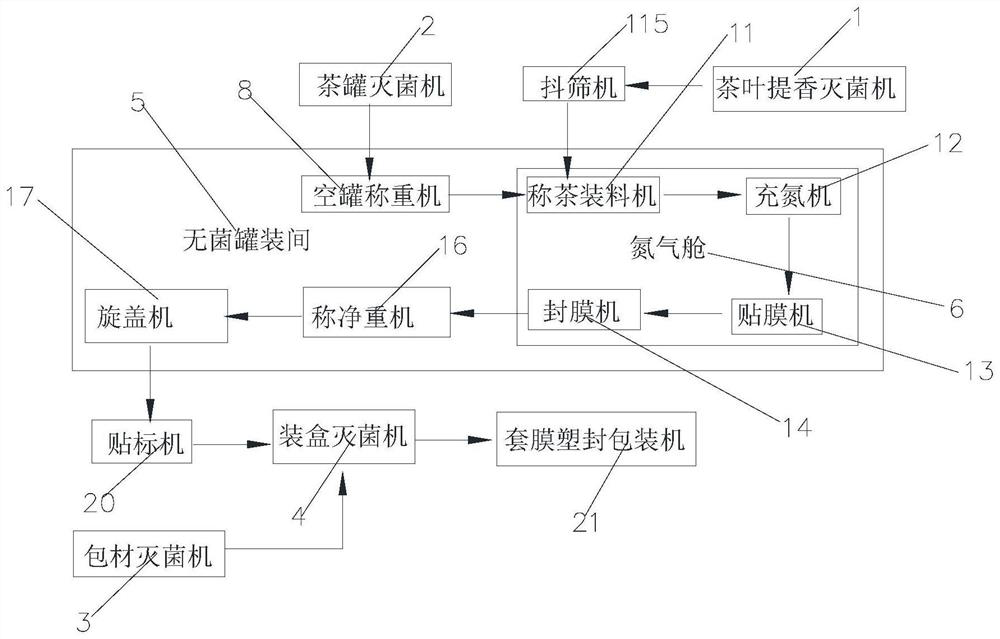

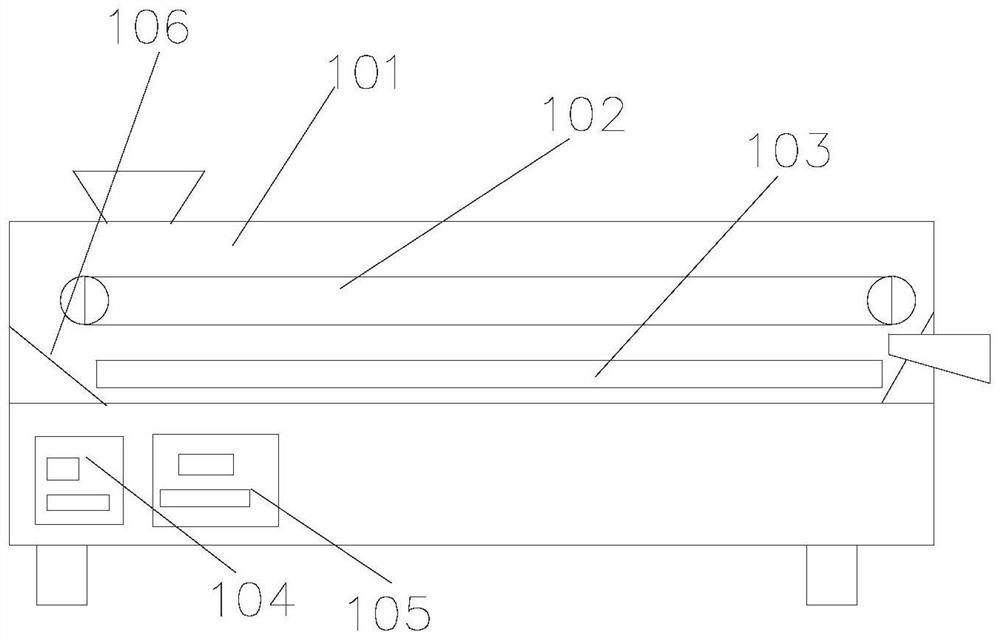

[0028] Examples such as Figures 1 to 9 Shown is a continuous production line for multi-bubble tea in small cans. The production line includes a tea aroma sterilization module for sterilizing tea leaves, a packaging material sterilization and impurity removal module for packaging materials, and nitrogen-filled tea leaves. Canning modules and plastic packaging modules. Through the mutual connection and cooperation of the above four modules, a continuous production line for multi-bubble tea in small cans is formed, which realizes the sterilization, automatic canning, nitrogen filling and plastic sealing of tea leaves and packaging materials. The whole process is processed by mechanical automation, which has high processing efficiency and ensures that the tea leaves will not be subject to secondary pollution during canning. The production line also solves the problems that the traditional production line does not sterilize the packaging materials, easily causes secondary polluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com