Spoke performance improving method applied to liquid die forging hub product

A liquid die forging and spoke technology, which is applied in the direction of wheels, wheel manufacturing, spoked wheels, etc., can solve the problem that the mechanical properties of the spoke part are lower than that of the rim and the rim part, so as to avoid the deformation of the spoke, improve the production efficiency, reduce the The effect of the amount of hub deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

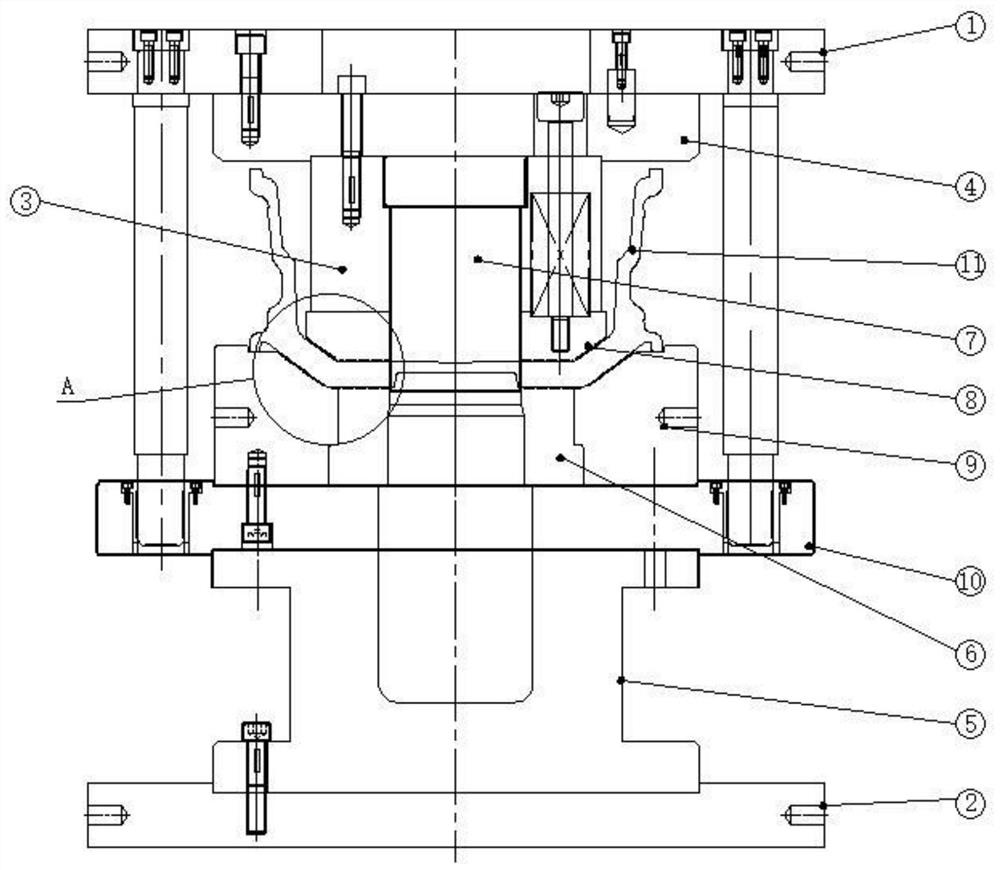

[0026] This embodiment is based on the liquid die forging process in CN106345984B with the publication number, the difference is that the extrusion of the spokes is added in step E, including the following steps:

[0027] A. Alloy composition optimization;

[0028] B. Melting: Melt the A357 aluminum ingot in a fast melting furnace and keep it warm;

[0029] C. Deslagging and degassing: Degas and deslag the melt obtained in step A with a high-efficiency refining agent in the furnace to make the melt clean and free of impurities; remove impurities and gases inside the aluminum alloy melt, which can further improve the purity of the alloy. Improve the metallographic structure of the alloy, eliminate internal defects such as shrinkage cavities, porosity, pores, and cracks in the product, and improve the surface quality of the workpiece at the same time;

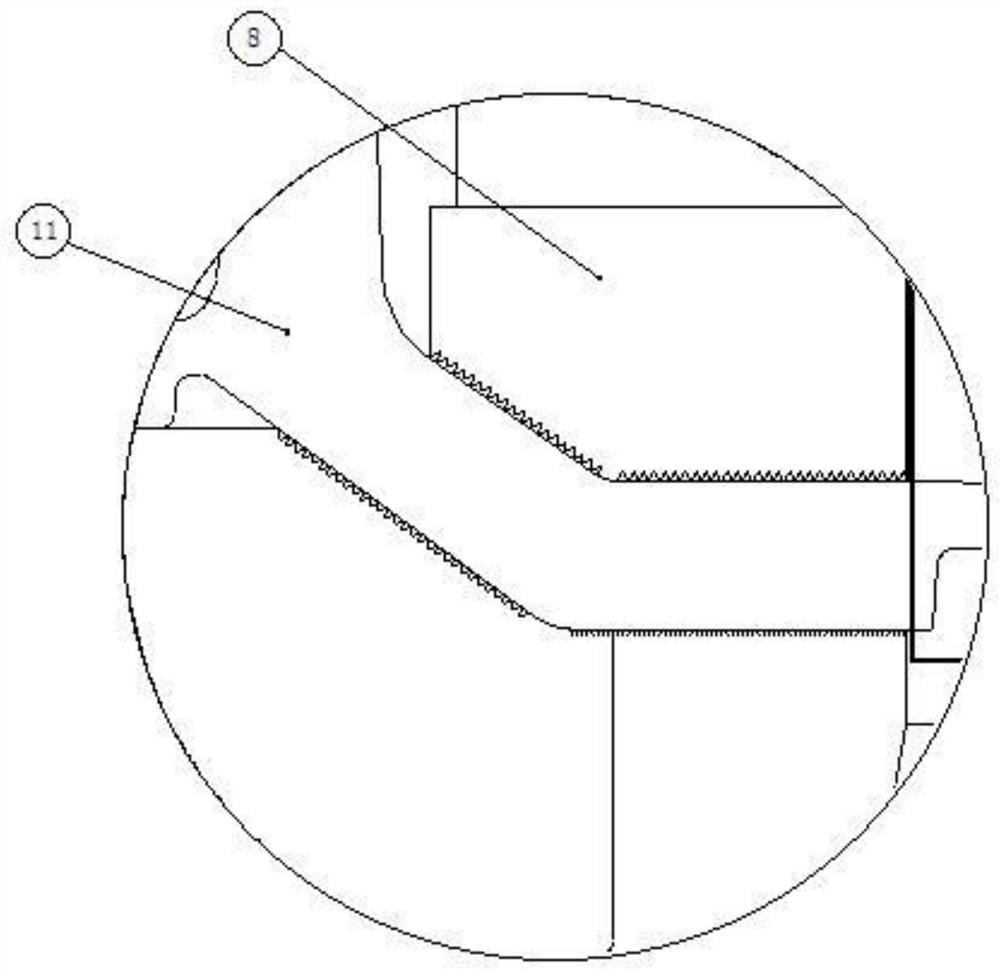

[0030] D. Liquid die forging: the wheel hub blank 11 is obtained, the wheel hub blank 11 includes the rim and the spokes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com