A joint blank forging forming process

A technology of forging and blanking, which is applied in the field of joint blank forging and forming technology, can solve the problems of low strength and poor mechanical properties, and achieve the effects of improving mechanical properties, increasing strength and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

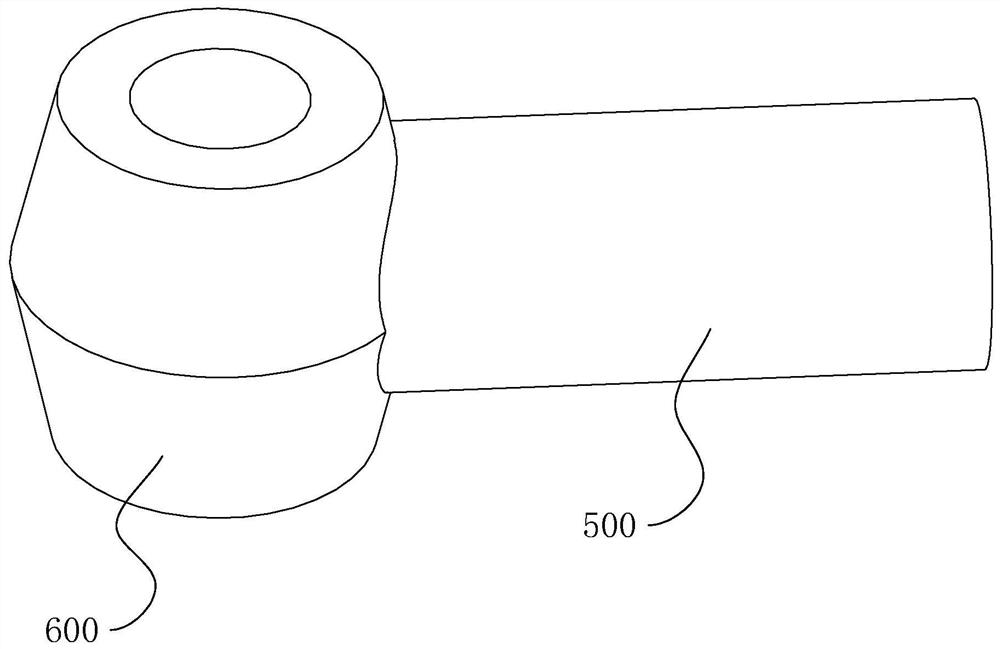

[0066] Attached to the following Figure 1-8 This application will be described in further detail.

[0067] The embodiment of the present application discloses a joint blank forging forming process.

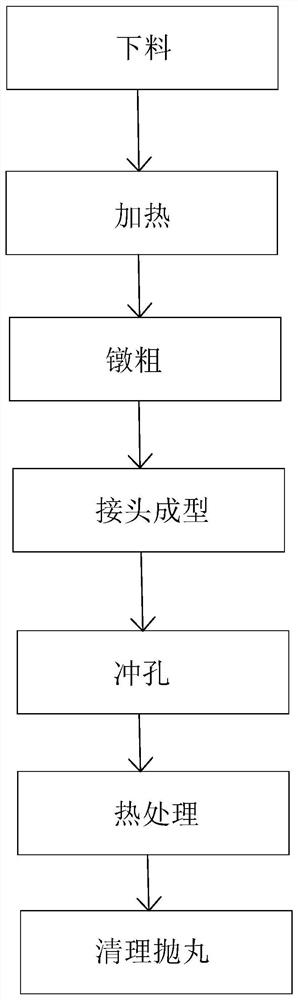

[0068] refer to figure 2 , The joint blank forging forming process includes the following steps: S1, blanking; S2, heating; S3, upsetting; S4, joint forming; S5, punching; S6, heat treatment; S7, cleaning shot blasting.

[0069] In S1, round steel is used as the base material, and a sawing machine is used to cut the base material into multiple shorter raw material columns according to the size of the joint blank to be processed.

[0070] In S2, the raw material column is heated by an intermediate frequency heating furnace.

[0071] In S3, the raw material column is forged with a punch to make the diameter of the raw material column thicker and the height shortened to form a raw material blank.

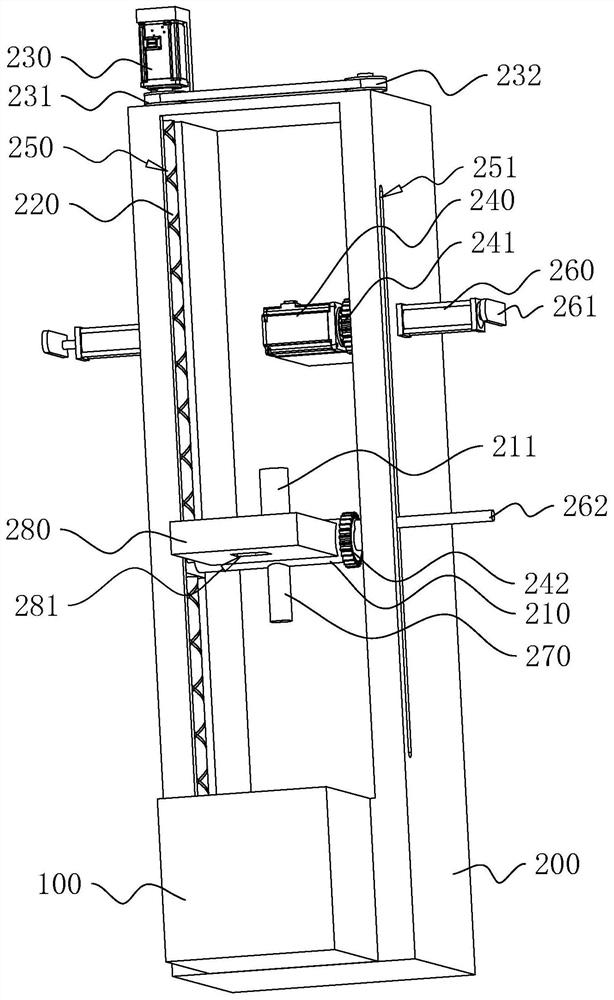

[0072] refer to image 3 , the punching machine includes a workbench 100 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com