Wire cutting machine

A technology of wire cutting machine and bearing block, which is applied in the direction of electric processing equipment, metal processing equipment, accessory devices, etc., can solve the problems that the bearing plate is easy to shake, and the fixing effect of the bearing plate is not realized, so as to achieve the effect of increasing fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-3 The application is described in further detail.

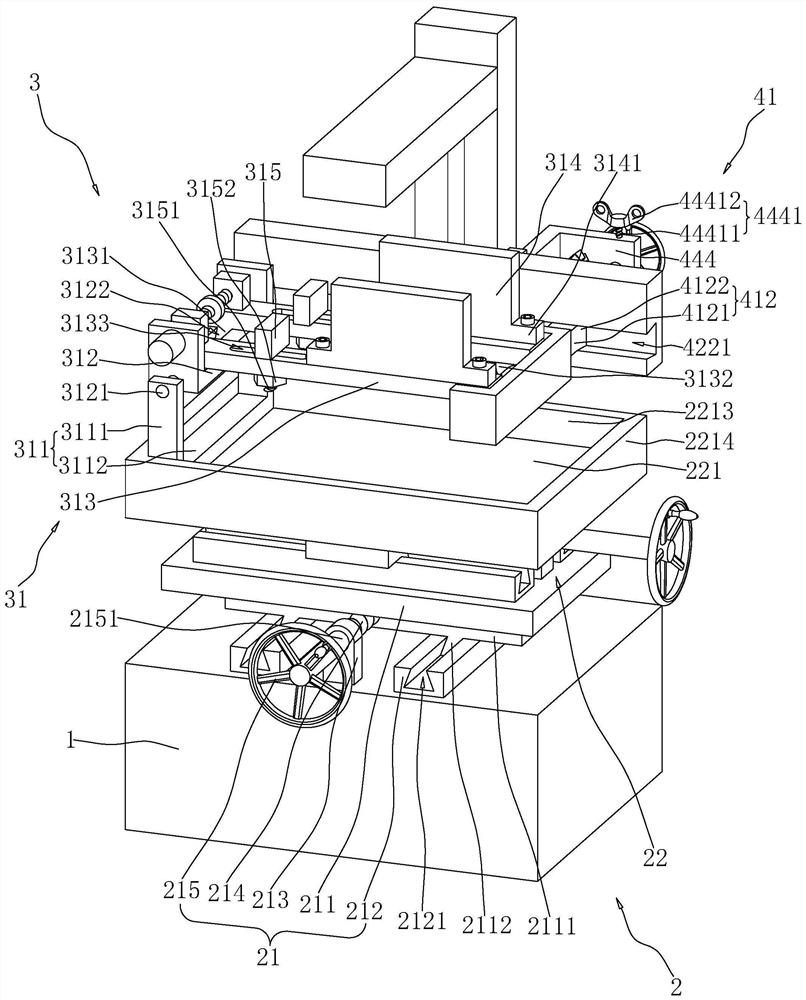

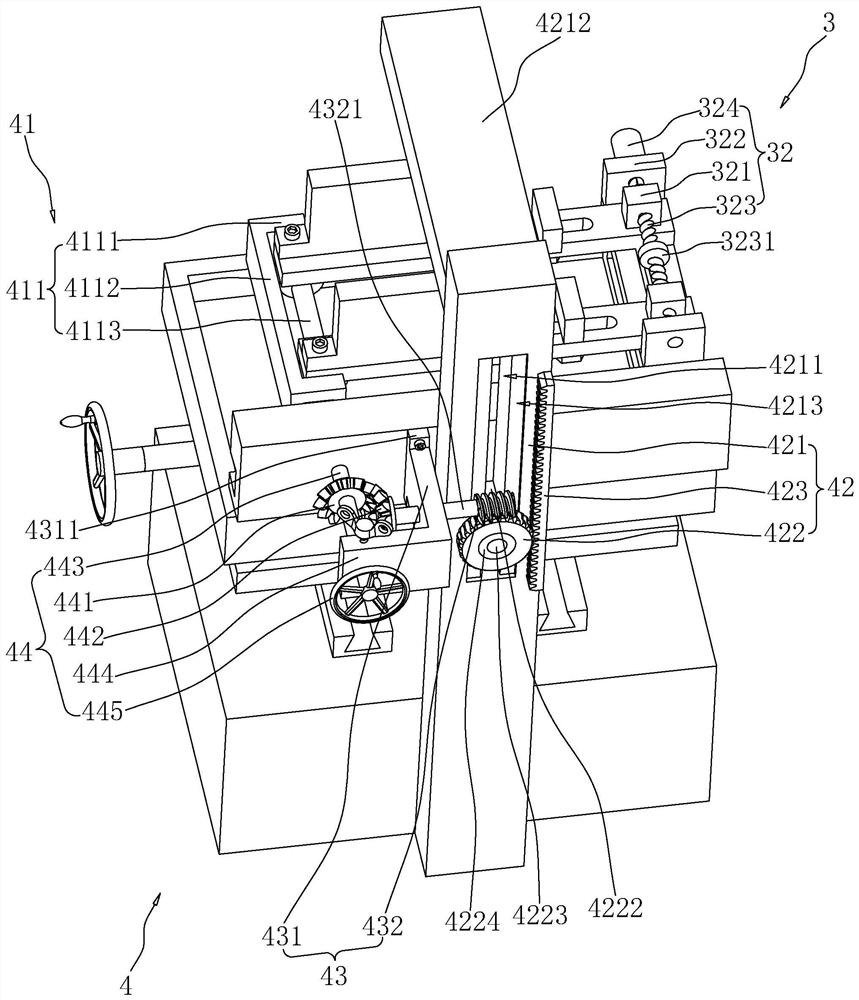

[0040] The embodiment of the application discloses a wire cutting machine. refer to figure 1 and figure 2 , The wire cutting machine includes a workbench 1, a sliding device 2, a clamping device 3, an adjusting device 4 and a cutting device. The shape of the workbench 1 is a cuboid, and the horizontal section of the workbench 1 is a rectangle. The sliding device 2 is installed on the upper surface of the workbench 1, the clamping device 3 is installed on the sliding device 2, the clamping device 3 is used to clamp the workpiece, and the sliding device 2 is used to drive the clamping device 3 to slide in the horizontal direction , the adjusting device 4 is used to adjust the angle of the clamping device 3, and the cutting device is used to cut the workpiece.

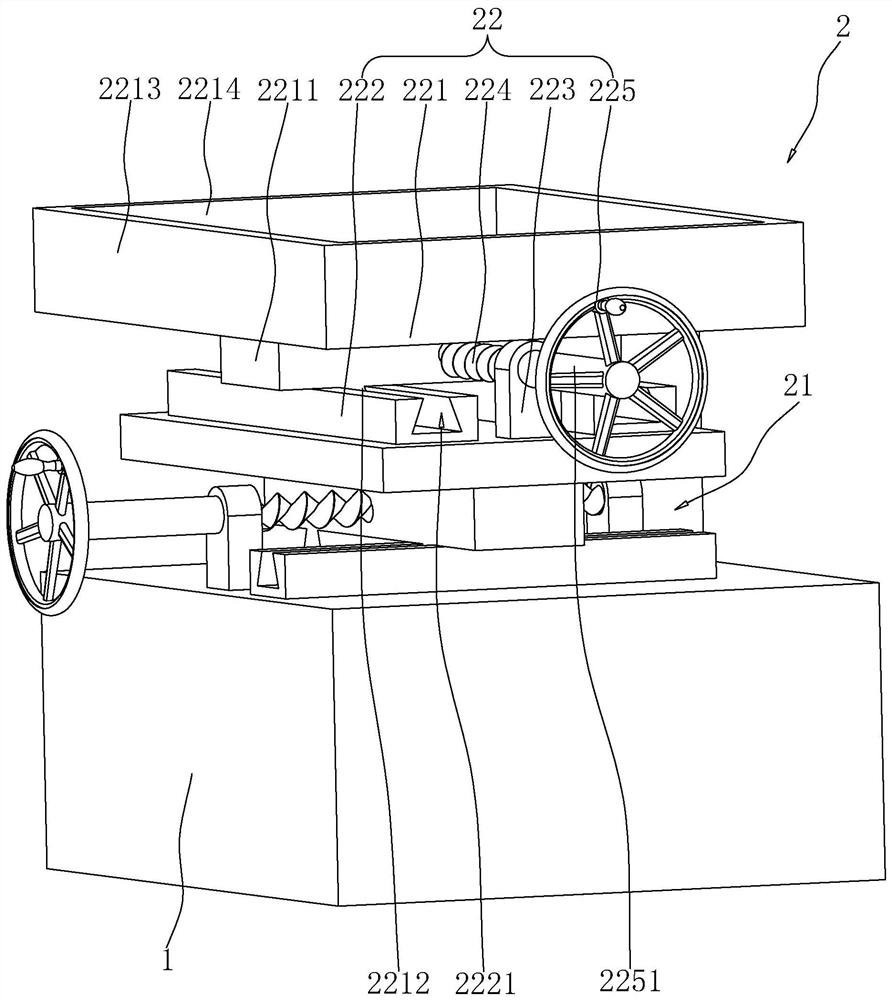

[0041] refer to figure 1 and image 3 , the sliding device 2 includes a first sliding mechanism 21 and a second slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com