T-shaped pipe network three-stage axial flow gas-liquid separation device and real-time control system

A technology of gas-liquid separation device and real-time control system, applied in separation methods, liquid degassing, rapid degassing, etc., can solve the problems of blockage, low separation efficiency, long residence time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

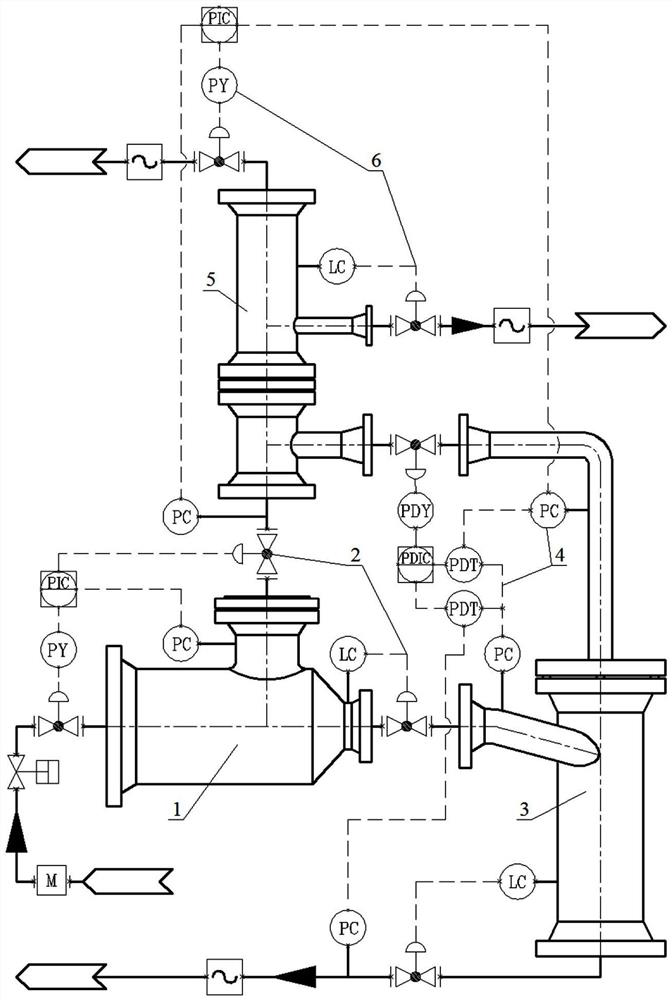

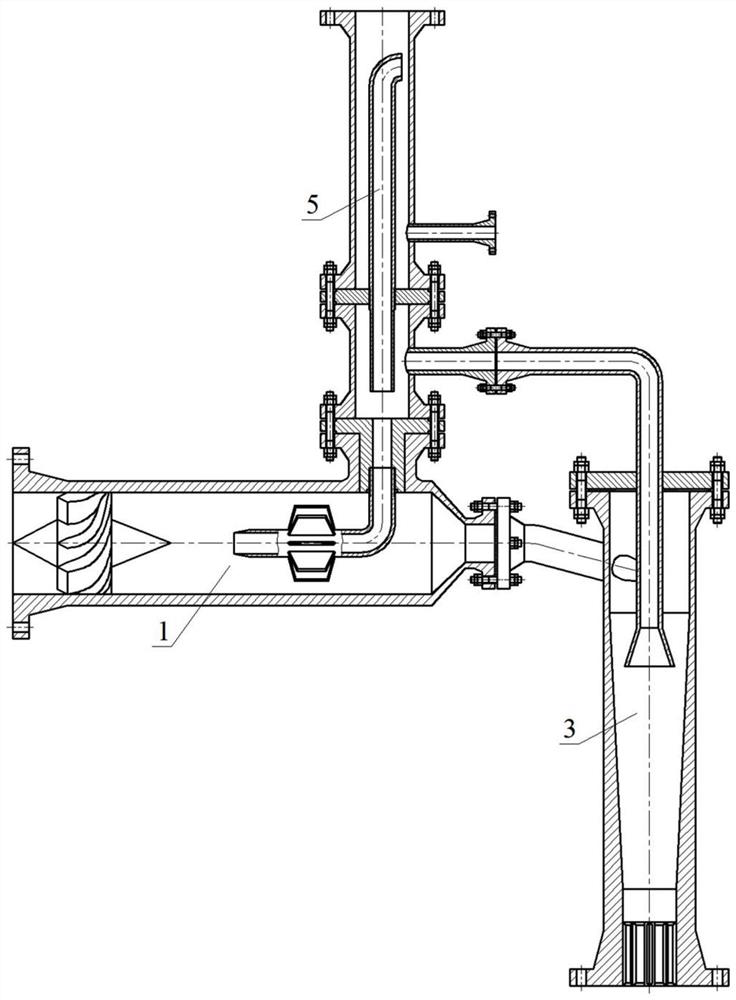

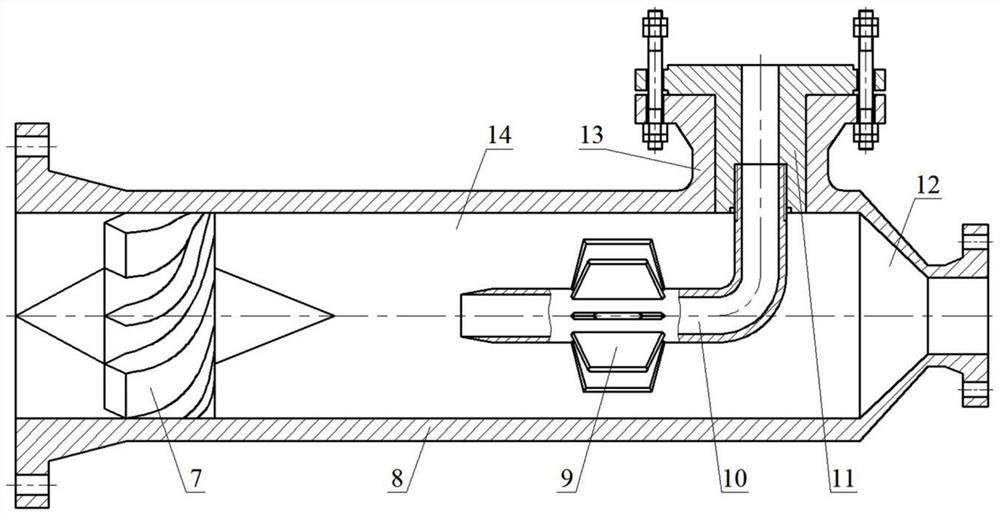

[0045] exist figure 1 and figure 2 Among them, the T-type pipe network three-stage axial flow gas-liquid separation device and real-time control system include the first-stage axial flow degasser 1, the first-stage axial flow degasser control system 2, the second-stage cyclone degasser 3, the second-stage Stage 4 cyclone degasser control system, 3rd stage jet degasser 5 and 3rd stage jet degasser 6, 1st stage axial flow degasser 1, 2nd stage cyclone degasser 3 and 3rd stage The jet degassers 5 are connected by flanges to form a T-shaped pipe network and realize three-stage axial flow gas-liquid separation of gas-containing well fluid.

[0046] exist figure 1 and figure 2 Among them, the three-stage axial flow gas-liquid separation device and real-time control system of the T-shaped pipe network implement the first-stage four-stream axial flow rapid degassing operation based on the first-stage axial flow degasser 1, and remove most of the liquid phase of the gas-bearing we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com