Beefsteak processing, forming and pressing device

A technology for processing and shaping steaks, which is applied in the fields of meat processing, slaughtering, food science, etc., can solve the problems of not being able to guarantee the consistency of steaks from the factory, unfavorable product sales and promotion, and inability to achieve continuous feeding, etc., to achieve stable and reliable undertaking, The effect of reducing interval time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

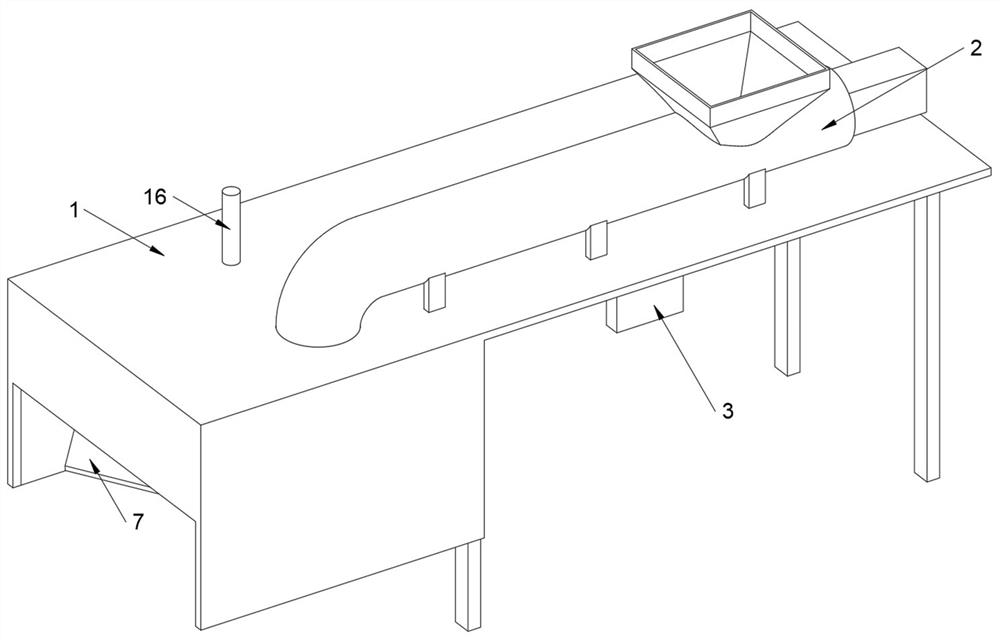

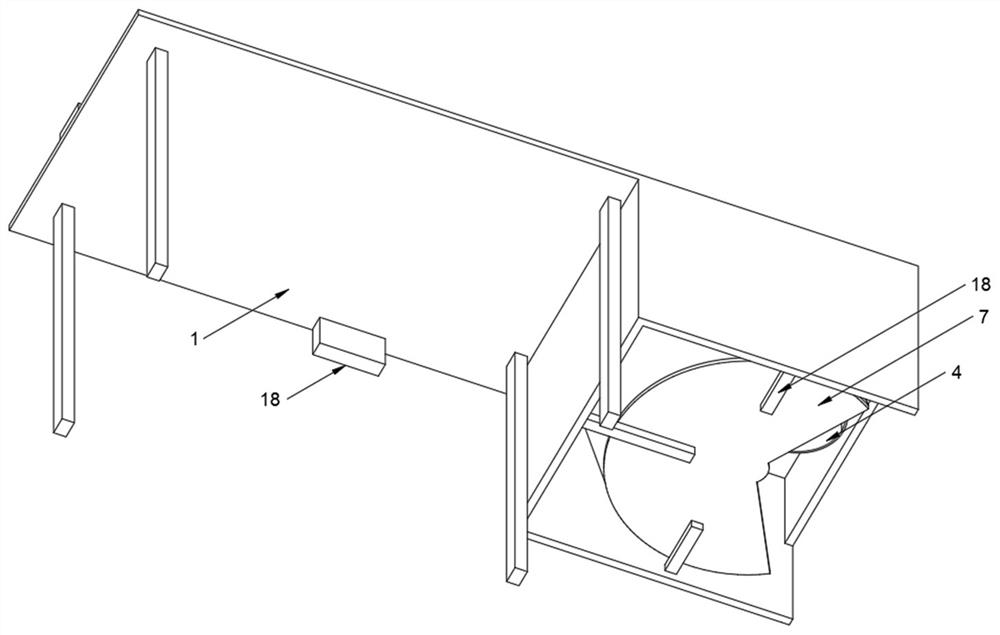

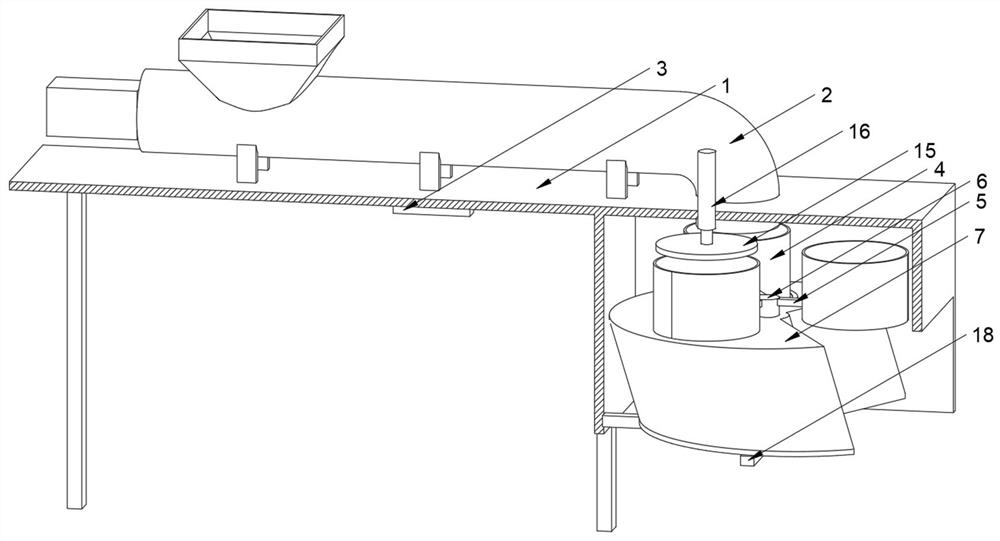

[0026] see Figure 1-Figure 7 , the present invention provides the following technical solutions: a beefsteak processing and molding pressing device, including a frame body 1, a screw feeding mechanism 2 is fixedly installed on the top surface of the frame body 1, and the lower right side of the frame body 1 is fixed by a support frame 18 An outer casing 7 is installed, and the top surface of the outer casing 7 is provided with an installation groove 8, and a pressure sensor 9 and a relay 17 are fixedly installed inside the installation groove 8, and the top surface of the pressure sensor 9 is fixedly connected to the weighing panel 10, the edge of the top surface of the weighing panel 10 and the edge of the installation groove 8 are provided with a groove body for fixing and bonding a fixing belt 11, and a stepping motor 12 is fixedly installed inside the outer shell 7, and the stepper The output shaft of the motor 12 is fixedly equipped with a dial 13, and the dial 13 is mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com