Handbag making machine

A handbag and bag making machine technology, which is applied in bag making operations, container manufacturing machinery, flexible container manufacturing, etc., can solve the problems of easy food to escape from the bag mouth, stealing food is not easy to be found, and lack of privacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

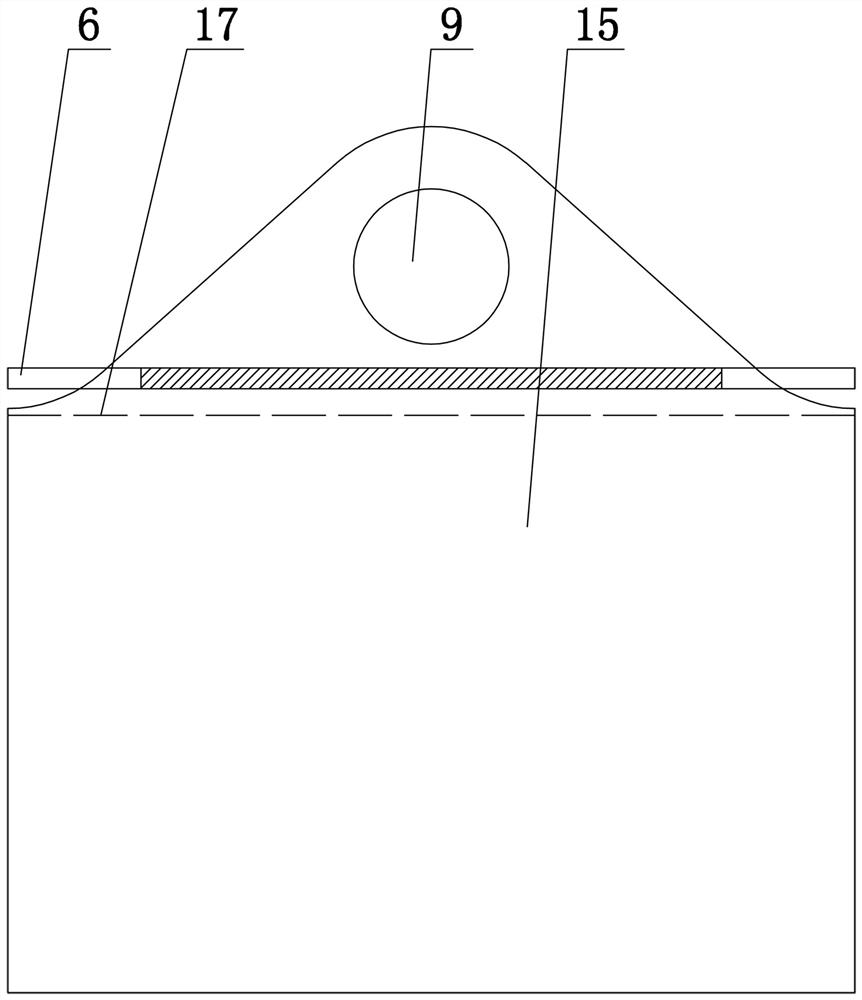

Image

Examples

Embodiment approach

[0031] The cartridge bag mechanism also includes a main steering mechanism including a left guide group and a right guide group, the including the left guide; the right guide group includes a right guide. Left, right guide changes the direction of transport of left main materials and right main materials, or may change the spacing of the two. The left guide includes a guide rod and a guide rod two, and the right guide includes a guide rod three and a guide rod four, the guide rod, a guide rod, the guide rod three and the guide rod four average The tilt setting is the same as the tilt direction of the guide rod three, and the guide rod is the same as the tilt direction of the guide rod, the guide rod three is the same as the tilt direction of the guide rod four, the left main material. The guiding rod is directed to the guide rod, and the conveying direction of the left main material is consistent with the conveying direction of the original material, and the right main material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com