Tool clamp specially for shape correction of blade

A tooling fixture and shape correction technology, which is applied in the direction of manufacturing tools, feeding devices, metal processing, etc., can solve the problem that it is difficult to accurately grasp the angle of blade shape correction, the data judgment basis cannot be provided for the same type of blade shape correction, and the consistency of blades is difficult. Guarantee and other issues, to achieve the effect of shortening the time of shape correction, precise shape correction, and improving the accuracy of shape correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

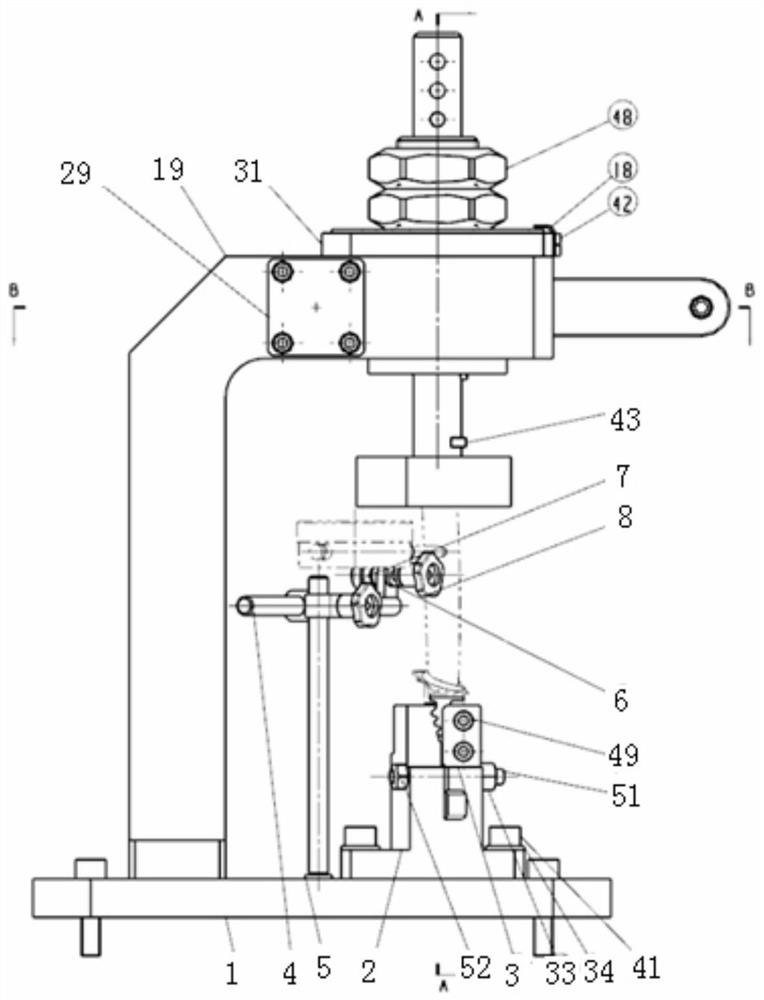

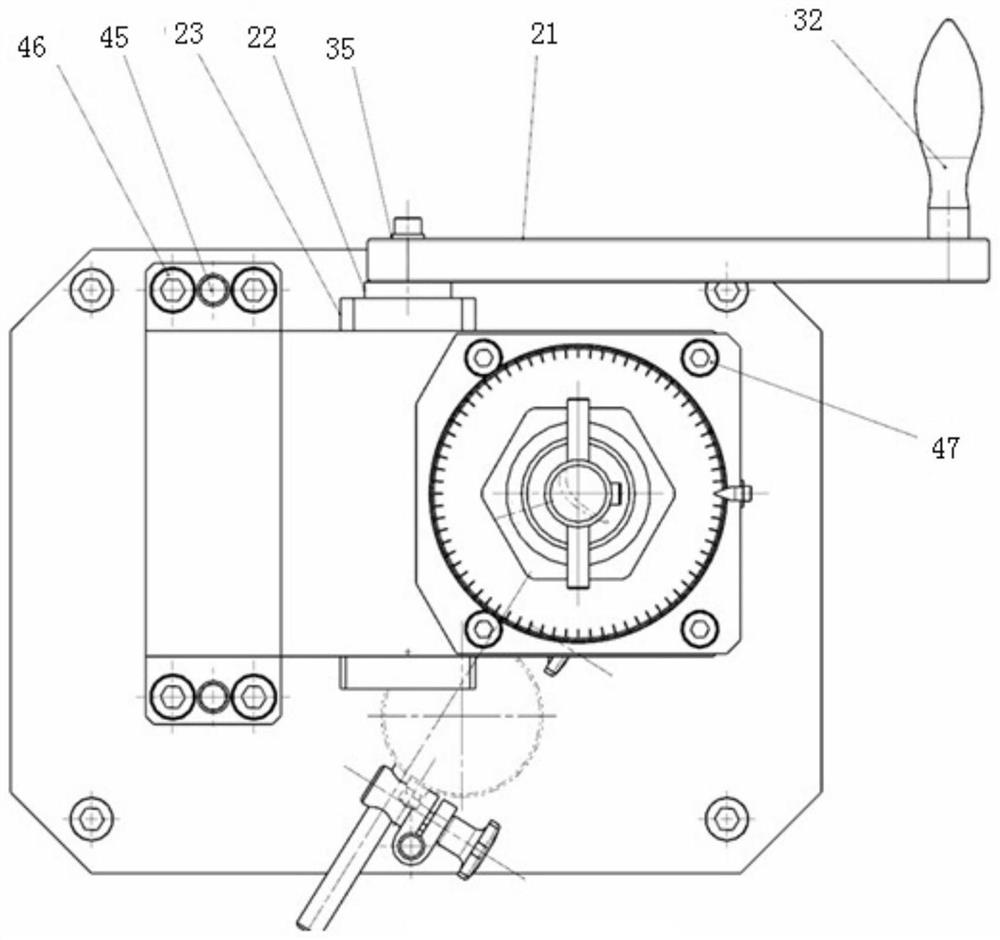

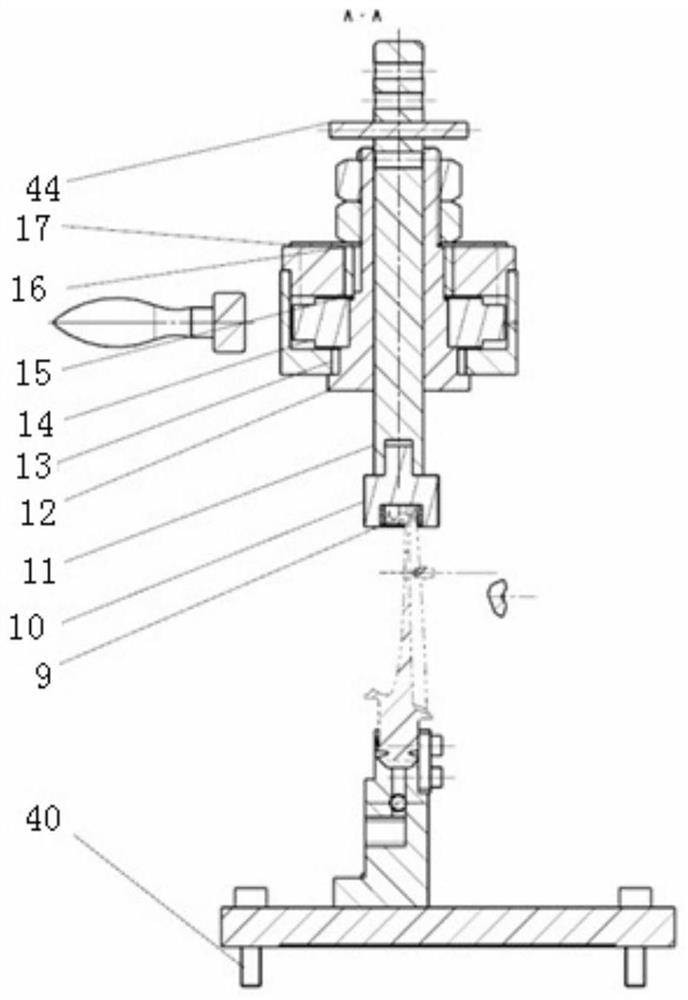

[0042] like Figure 1-4 Shown is a special tooling fixture for blade shape correction, including base plate 1, positioning block 2, baffle plate 3, beam 4, column 5, table clamp 6, screw 7, star nut 9, spacer 9, torque transmission sleeve 10 , Tightening rod 11, rotating shaft 12, bushing a13, turbine 14, adjusting gasket 15, bushing b16, scale gasket 17, pointer 18, positioning seat 19, blocking cover a20, handle 21, washer 22, blocking cover b23, worm 24, felt ring 25, sleeve 28, clip 29, pull rod 30, blocking cover c31;

[0043] The main body of the bottom plate 1 is a cuboid, and the cuboid is provided with mounting holes, and four light holes are provided at the four corners, which are used to fix the overall structure of the fixture on the worktable through hexagon socket head screws a40, and the mounting holes are used for fixing and positioning Block 2, column 5 and positioning seat 19;

[0044] The positioning block 2 is a cuboid, and the positioning block 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com