Shell breaking, retention and desliming system of machine-made sand and desliming process thereof

A technology of machine-made sand and shell breaking, applied in grain processing and other directions, can solve the problem of low production efficiency, and achieve the effect of improving quality and reducing pretreatment processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Pass the natural soil sample taken through a 3.0mm mesh sieve to separate impurities such as pebbles and tree roots.

[0040] Take 30Kg of sieved soil sample and adjust it into mud with 15L of water. Put 100Kg of gravel into the mud, make the mud evenly wrap the surface of the gravel, take it out and let it dry naturally at room temperature for 12 hours. Record the total mass W1 of the mud-coated gravel sample after air-drying.

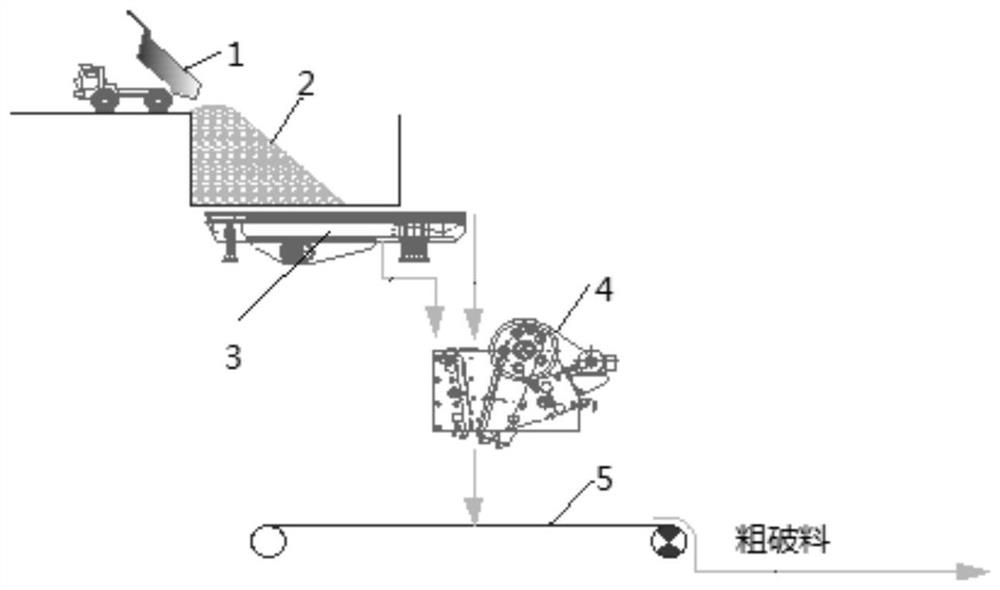

[0041] S1. The unloading hopper 2 feeds the material in the dump truck 1 into the coarse crusher 4 for crushing;

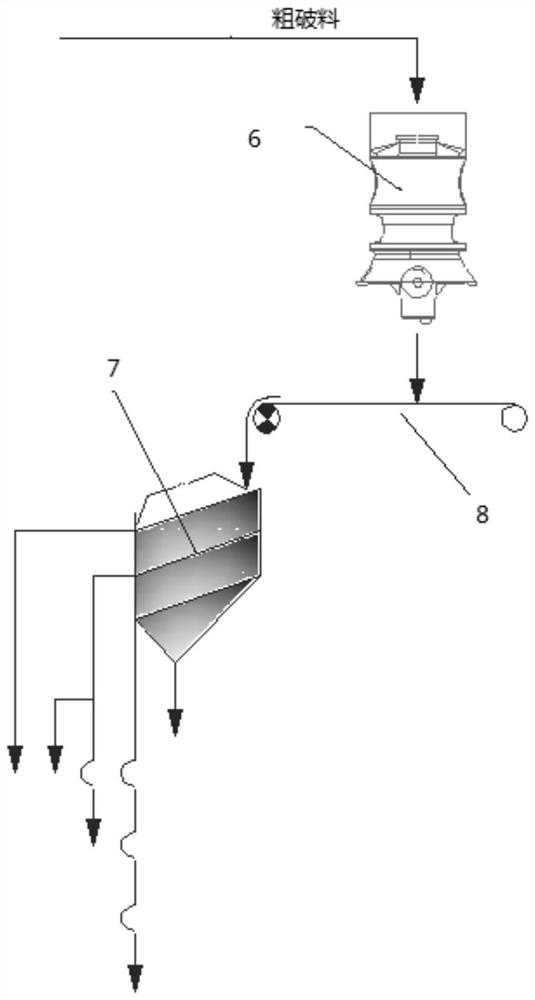

[0042] The material crushed by the coarse crusher 4 is transported to the secondary crusher 6 through the first conveyor belt 5;

[0043] Secondary crusher 6 crushes the medium material, and then transports the material to the compound sieve 7 through the second conveyor belt 8 for screening, then weighs the weight of the finished material W2 and the useless material W3 respectively

[0044] W2 is 98Kg, and W2 is 32Kg.

Embodiment 2

[0046] In this embodiment, by controlling the conveying speed of the conveyor belt, the feeding speed is adjusted between the crusher and the vibrating screen according to different materials and their attachments, so that the crusher can fully deslim the materials;

[0047] During the implementation process, the feeding speed of the bar feeder 3, the first conveyor belt 6, and the second conveyor belt 8 is 100 tons / hour, and the surface of the material screened by the vibrating screen has no soil adhesion.

Embodiment 3

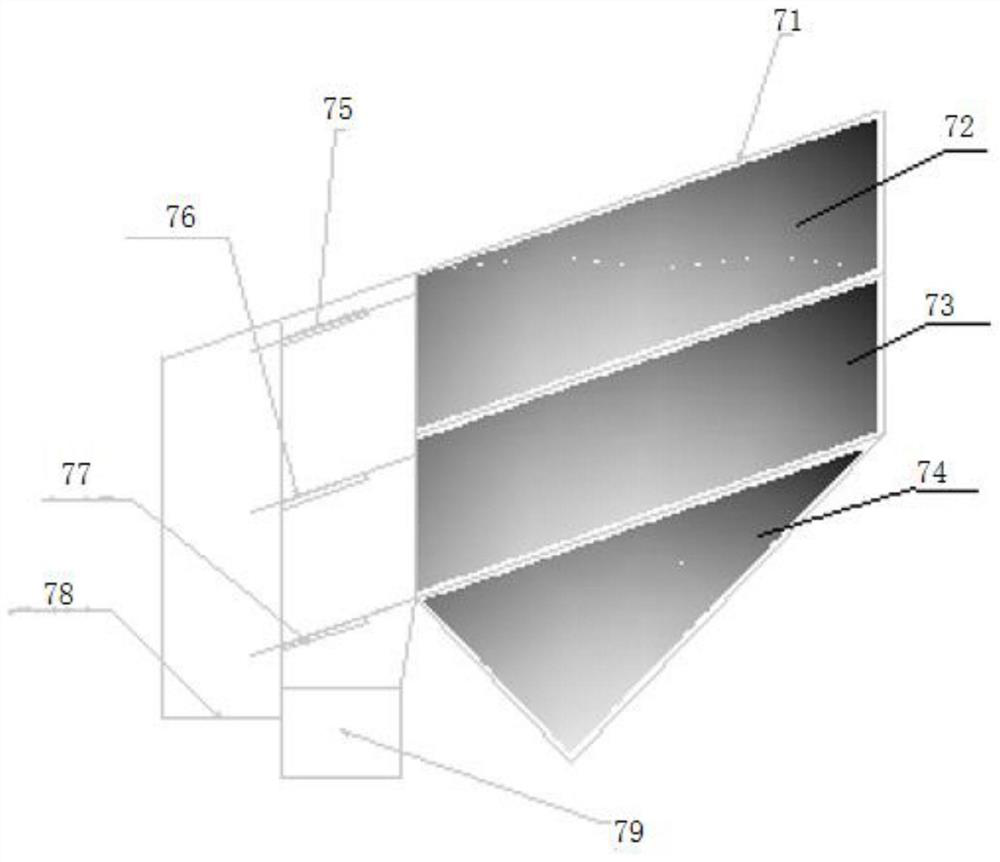

[0049] Such as image 3 As shown, the first screen 2, the second screen 3, and the third screen 4 are set in the vibrating screen 1. If there is no particle size of the material, the third screen needs to be used, and the fine material first enters through the inlet port of the vibrating screen. The first sieve, the larger-sized aggregates are left on the screen surface of the first sieve 2, and under the action of the vibrating screen, they are piled up at the outlet and blocked by the first reversing door 5 to prevent them from falling. The material falls on the second screen 3 and is screened, and the same material with larger particle size remains on the screen surface of the second screen and accumulates to its outlet, and is blocked by the second reversing door 6; then the material with smaller particle size falls On the third sieve 4, the third sieve 4 keeps the aggregate with smaller particle size on the sieve surface for storage, and the fine useless materials fall in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com