Lead-acid battery with gradient polar plates

A lead-acid battery, gradual change technology, applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc., can solve the problems of unfavorable cost control, low material utilization rate, low service life, etc., and achieve charging uniformity Improve, reduce occupied volume, prolong the effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

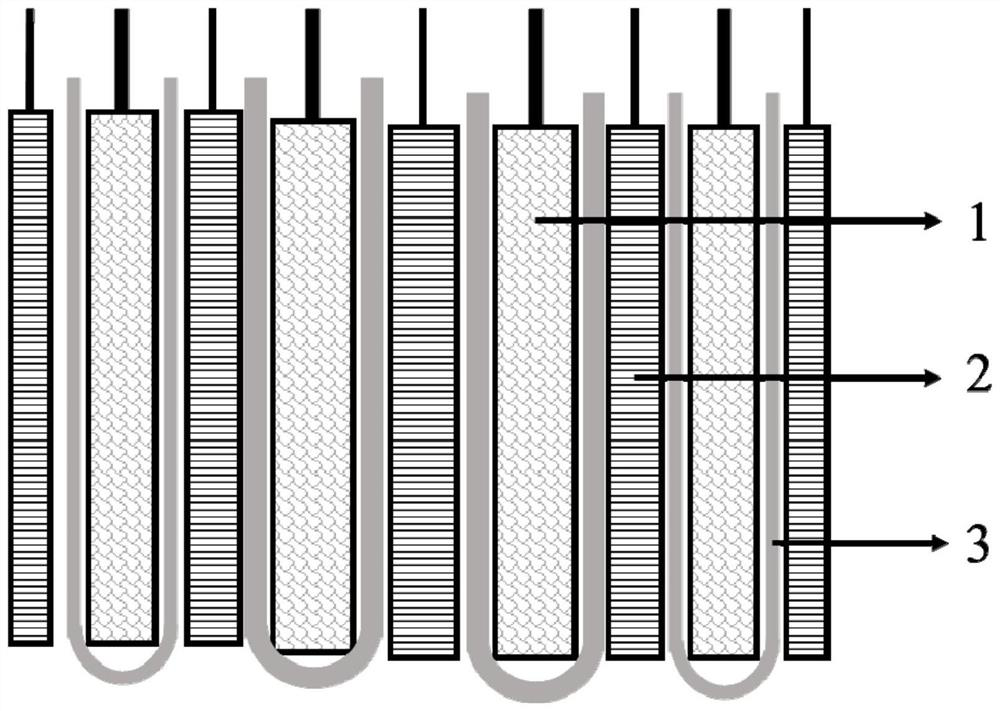

[0018] A 12V20Ah power battery is prepared through a gradient plate design. The battery is designed as six 2V20Ah pole groups, and each pole group adopts a structure of 4 positive and 5 negative, that is, the pole group includes 4 positive plates 1 and 5 negative plates 2 .

[0019] like figure 1 As shown, the thicknesses of the four positive plates 1 are 2.3 mm, 2.5 mm, 2.5 mm, and 2.3 mm from left to right, that is, the thicknesses of the two positive plates 1 in the middle are both 2.5 mm.

[0020] Among them, the active material coated on the positive electrode plate 1 with a size of 2.5 mm is 94 g, and the active material coated on the positive electrode plate 1 with a size of 2.3 mm is 82 g.

[0021] Among them, the thickness dimensions of the five negative plates 2 are 1.3mm, 1.6mm, 1.7mm, 1.6mm, and 1.3mm from left to right, that is, the thickness of the middle negative plate 2 is 1.7mm.

[0022] Among them, the active material coated on the negative electrode plate 2...

Embodiment 2

[0026] A 2V300Ah power battery is prepared through a gradient plate design. The battery is designed as one pole group, and the pole group adopts a structure of 6 positive and 7 negative, that is, the pole group includes 6 positive plates 1 and 7 negative plates 2 .

[0027] Among them, the thickness of the six positive plates 1 is 4.5mm, 5.0mm, 5.5mm, 5.5mm, 5.0mm, and 4.5mm from left to right, that is, the thickness of the two positive plates 1 in the middle is 5.5mm, and the positive plates 1 on both sides are The thickness decreases from the middle to both sides.

[0028] Among them, 1000g of active material is coated on the positive electrode plate 1 of 5.5mm size, 800g of active material is coated on the positive electrode plate 1 of 4.5mm size, and 650g of active material is coated on the positive electrode plate 1 of 3.5mm size.

[0029] Among them, the thickness dimensions of the seven negative plates 2 are 2.2mm, 2.7mm, 3.0mm, 3.2mm, 3.0mm, 2.7mm, and 2.2mm from left ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com