Cable joint discharge live detection method based on high-speed light sensation and pressure wave technologies

A cable joint, live detection technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of inability to eliminate the relative noise of high-speed photosensitive light sources, inability to detect, etc., achieve high signal-to-noise ratio, reduce the average number of times, The effect of high output frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for detecting live discharge of cable joints based on high-speed light sensing and pressure wave technology, comprising the following steps:

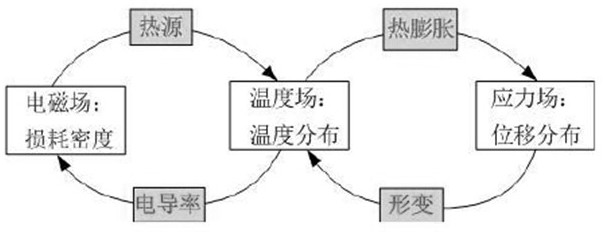

[0042] S1: Construct the discharge-pressure wave multiphysics coupling model in the cable joint;

[0043] S2: Use the pressure wave sensor, electric field sensor and temperature sensor to collect the pressure wave information, electric field distribution, electric field strength information and temperature information of the cable joint to be tested, and transmit them to the information processing unit;

[0044] S3: The information processing unit analyzes and processes the pressure wave information, electric field distribution, electric field intensity information and temperature information according to the discharge-pressure wave multiphysics field coupling model;

[0045] S4: According to the analysis results, determine the area of accumulated charge, that is, the hidden fault point.

[0046] The mathematical mode...

Embodiment 2

[0073] The cable joint discharge and liveness detection method based on high-speed light sensing and pressure wave technology in the embodiment of the present invention differs from the first embodiment in that:

[0074] The pressure wave must pass through the air from the device to be detected and then reach the pressure wave sensor. Due to the huge acoustic impedance difference between the equipment to be tested (including insulating materials, copper or aluminum semiconductors, etc.) and the air, most of the pressure wave energy is reflected back on the surface of the equipment to be tested, and the energy loss of the pressure wave is very large after it reaches the air. Large, so additional high-sensitivity detectors are required. The energy output is increased by coating the surface of the device under test with a material whose impedance is between the two, so as to compensate for the lack of signal energy at the detection end, which affects both the intensity and resolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com