Earthquake area UHPC temporary board room and erection method

A temporary, prefabricated house technology, applied in the direction of earthquake resistance, floors, walls, etc., to achieve the effect of increasing the resistance to lateral movement, saving building materials, and improving the tensile capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

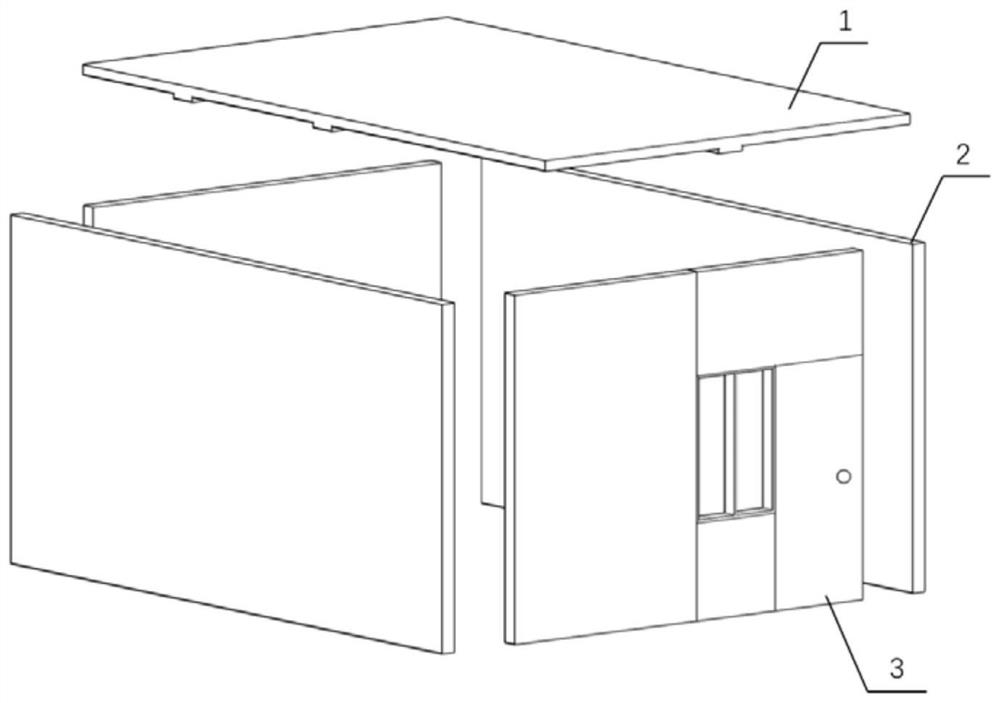

[0049] see Figure 1-Figure 6 , a UHPC temporary prefabricated house in an earthquake area provided by this embodiment includes a base plate, a UHPC prestressed wall 1 , a UHPC ribbed floor 2 and ancillary facilities 3 . The auxiliary facilities 3 include doors and windows, and the doors and windows are all set on the UHPC prestressed wall 1 .

[0050] In this embodiment, the bottom plate is made of concrete.

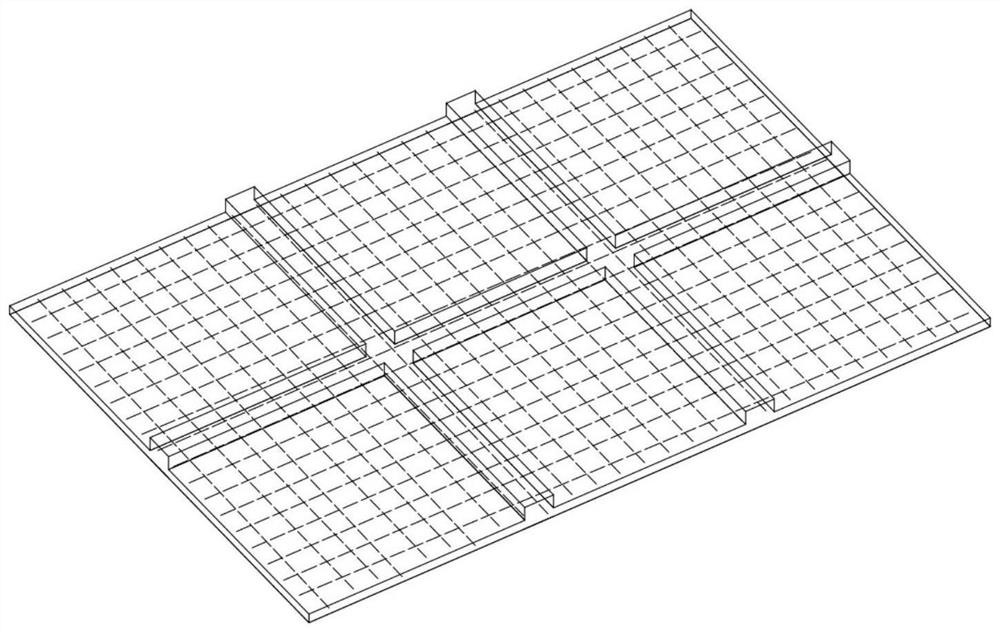

[0051] The UHPC prestressed wall 1 is fixed on the side of the bottom plate, and the UHPC prestressed wall 1 is provided with ordinary steel bars and prestressed steel bars in the wall, and the prestressed steel bars are fixed in the wall by pretensioning. Using UHPC prestressed wall 1 can effectively improve the overall stability of the wall. The UHPC prestressed wall 1 includes a plurality of UHPC wall panels, and the thickness of the UHPC wall panels is between 100mm and 200mm. The UHPC prestressed wall 1 is formed by splicing a plurality of UHPC wall panels in seq...

Embodiment 2

[0057] It is basically the same as Embodiment 1, except that this embodiment also provides a method for erecting a UHPC temporary prefabricated house in an earthquake area provided by Embodiment 1.

[0058] A method for erecting a UHPC temporary prefabricated house in an earthquake area, comprising the following steps:

[0059] 1. Foundation excavation, foundation treatment, laying out the outline of the prefabricated house, for the temporary construction of the prefabricated house, just ram and compact it directly, or directly choose hard soil as the foundation.

[0060] 2. For foundation construction, pour a layer of 150mm thick C20 concrete.

[0061] 3. Put the installation line, make sure the required size is accurate.

[0062] 4. Lift the UHPC prestressed wall through the lifting device.

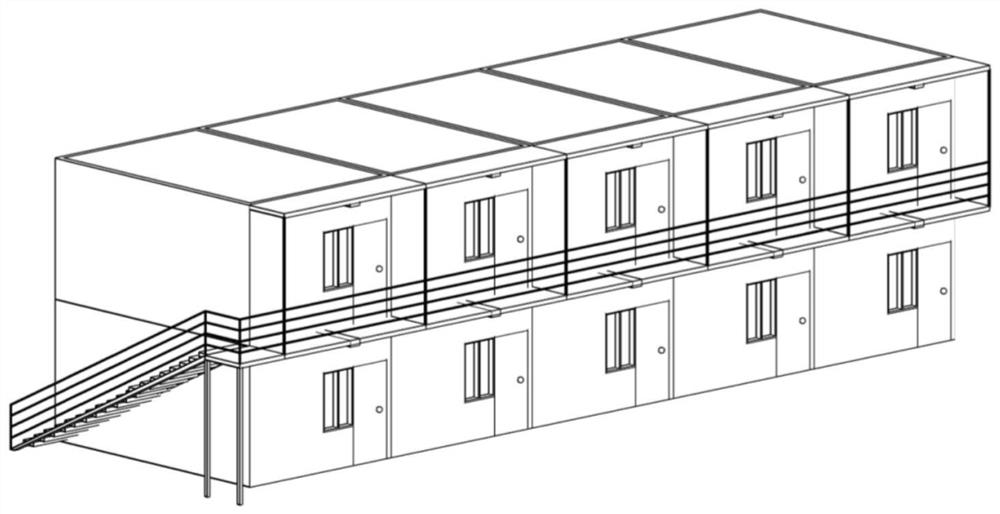

[0063] 5. Install the UHPC ribbed slab on the top of the UHPC prestressed wall through the lifting device. If a prefabricated house with upper and lower floors or more than two floor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com