Novel assembly type water plank road structure and construction method thereof

A prefabricated, plank road technology, applied in infrastructure engineering, erection/assembly of bridges, bridge parts, etc., can solve the problems of long construction period, low labor efficiency, high formwork cost, and achieve faster construction progress, reduce impact, and landscape effects. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

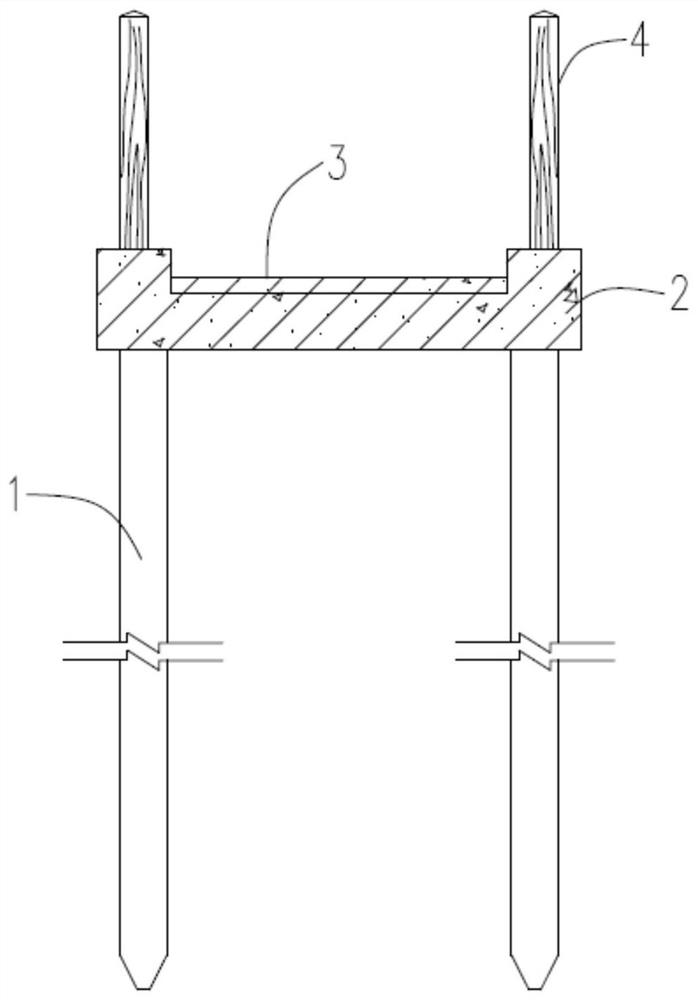

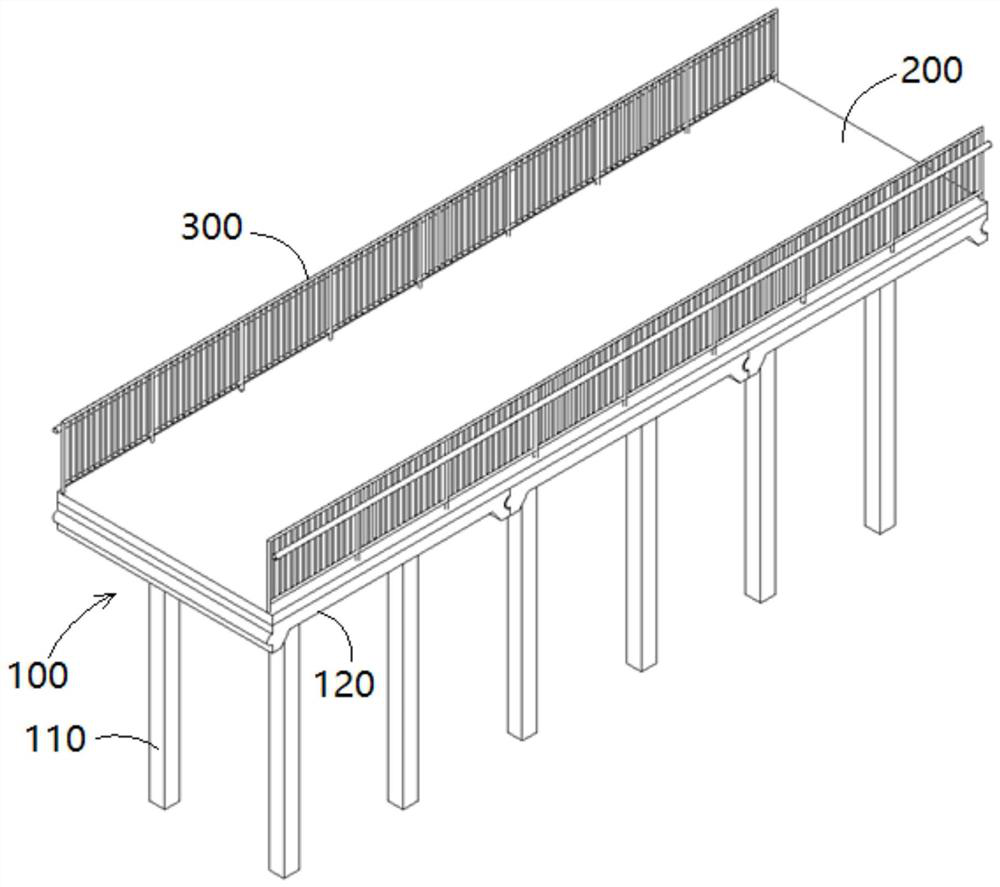

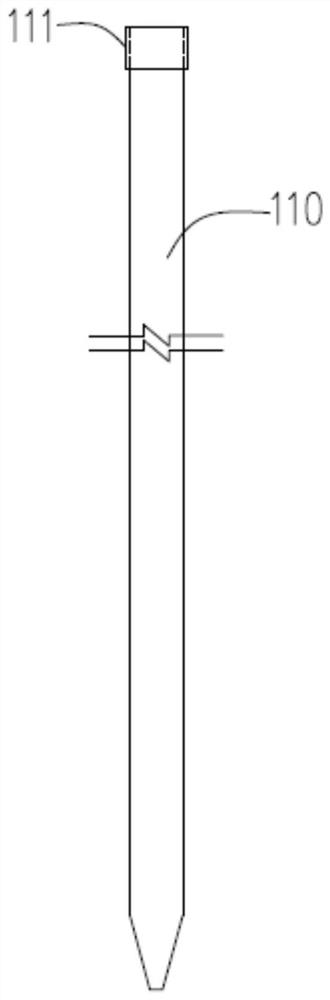

[0048] see figure 2 , shown in the figure is a new type of prefabricated plank road structure, which consists of several prefabricated plank road units 100 arranged side by side along the extension direction of the plank road. Each prefabricated walkway unit 100 includes four prefabricated pile foundations 110 and prefabricated beamless slabs 120 . Of course, the number of prefabricated pile foundations 110 is not limited to the number in this embodiment, it should be set according to the actual support requirements, and should be set at least three to provide stable support.

[0049]Four prefabricated pile foundations 110 are set at the river bank at intervals, and each prefabricated pile foundation 110 preferably adopts prefabricated square ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com