Trace oxygen generation module and pure oxygen generation system thereof

Oxygen generation and trace technology, applied in the direction of cells, electrolysis process, electrode shape/type, etc., can solve the problem of increased contact resistance on the anode side and cathode side, so as to avoid the increase of input voltage, ensure the output, and excellent electricity The effect of contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

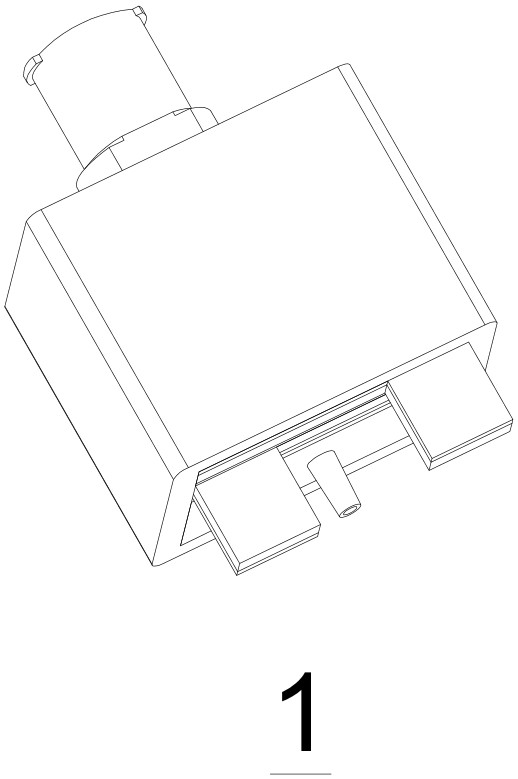

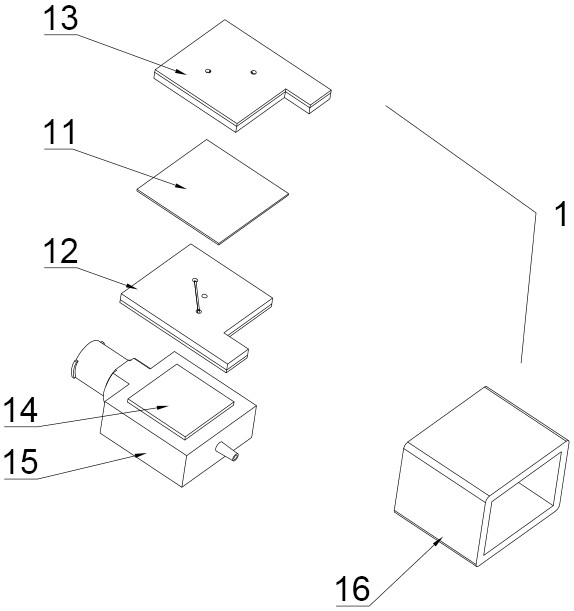

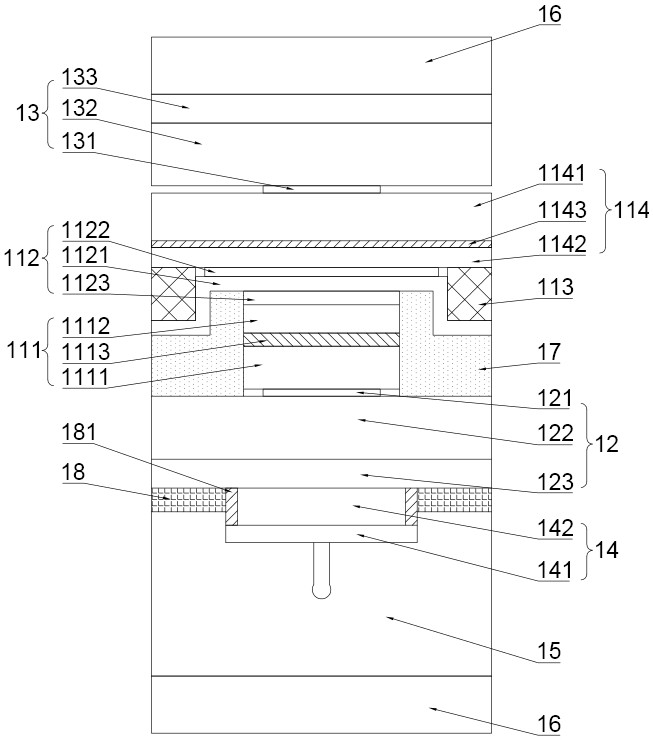

[0036] Trace oxygen generation module 1, such as Figure 1~Figure 6 As shown, it includes a cathode collector plate 13, a cathode support layer 114, a catalytic reaction layer 112, an anode support layer 111, and an anode collector plate 12 ( figure 2 Middle 11 is a cathode support layer 114, a catalytic reaction layer 112, an anode support layer 111 laminated membrane electrode) and a pure oxygen gas collection chamber 15, the cathode collector plate 13 and the anode collector plate 12 are equipped with current collector lines, the cathode Both the support layer 114 and the anode support layer 111 are provided with a conductive base layer, and the hardness of the conductive base layer is lower than that of the current collecting circuit. pressure and can maintain the state of being partially or fully embedded in the conductive base layer. In this embodiment, the current collecting circuit has a long and thin structure, specifically a strip structure, which is convenient for...

experiment example

[0060] The material and preparation process of each layer structure of the trace oxygen generation module in the above embodiments of the present invention are described as follows.

[0061] Cathode conductive layer 133: tin sheet size (length, width, thickness) 21mm×21mm×0.3mm.

[0062] Cathode non-conductive layer 132: PETG (glycol-modified polyethylene terephthalate), with a size of 21mm×21mm×2mm.

[0063] Cathode current collecting circuit 131 : palladium plating, width 0.1 mm, thickness 0.1 mm, plasma deposition.

[0064] Cathode conductive base layer 1141 (including water-transfer agent material and hygroscopic material): water-transfer agent material and hygroscopic material are respectively made of simethicone and silicon dioxide. Mix in the solvent formed by propanol and deionized water, the mass ratio of simethicone, silicon dioxide, ethanol, isopropanol and deionized water is 30:4:150:100:300, mix well to form a water-based suspension After immersing the carbon fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com