Fed-batch feeding method in fermentation production of neomycin sulfate

A neomycin sulfate and feeding technology, applied in fermentation and other directions, can solve the problems of bacterial contamination risk, high nutrient concentration and delayed feeding time in the entire feeding system, so as to reduce the risk of bacterial contamination and achieve high conversion rate. , the effect of strong mycelial metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A fed-batch feeding method in the fermentative production of neomycin sulfate, the method may further comprise the steps:

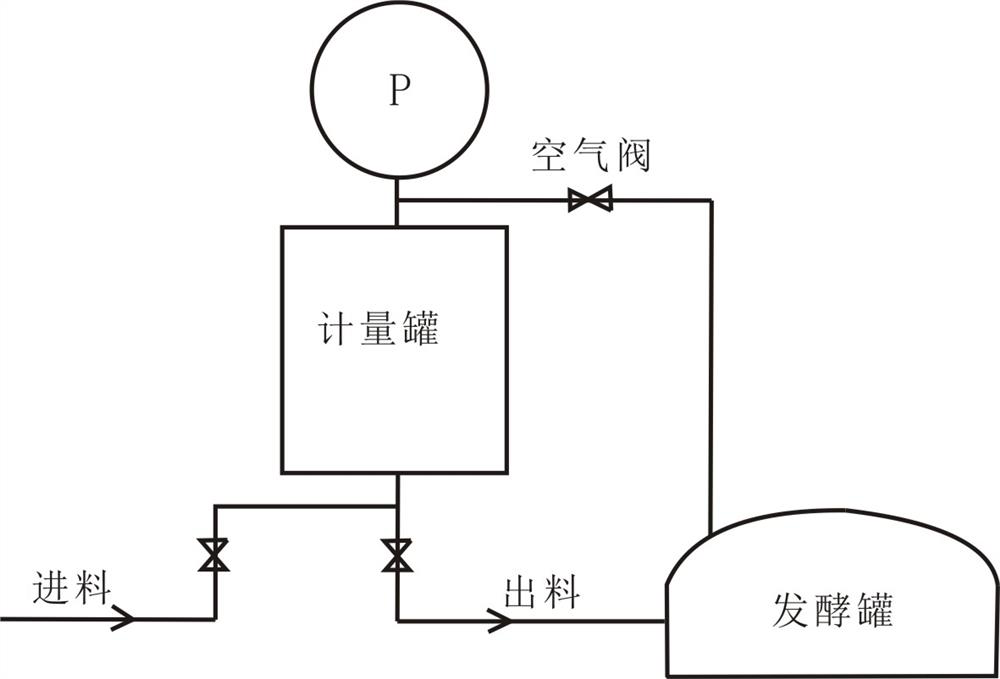

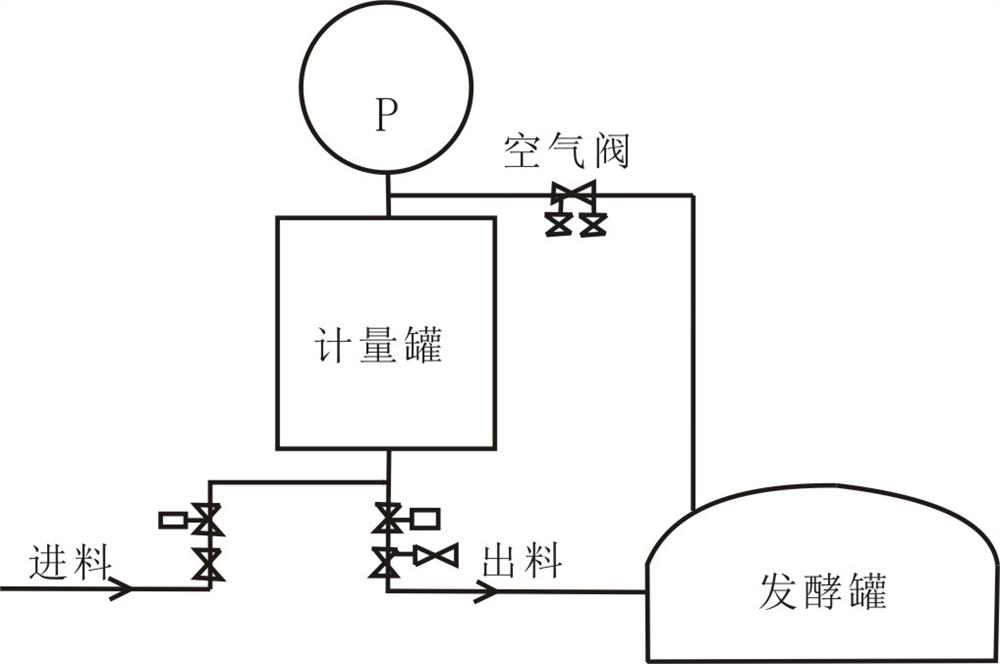

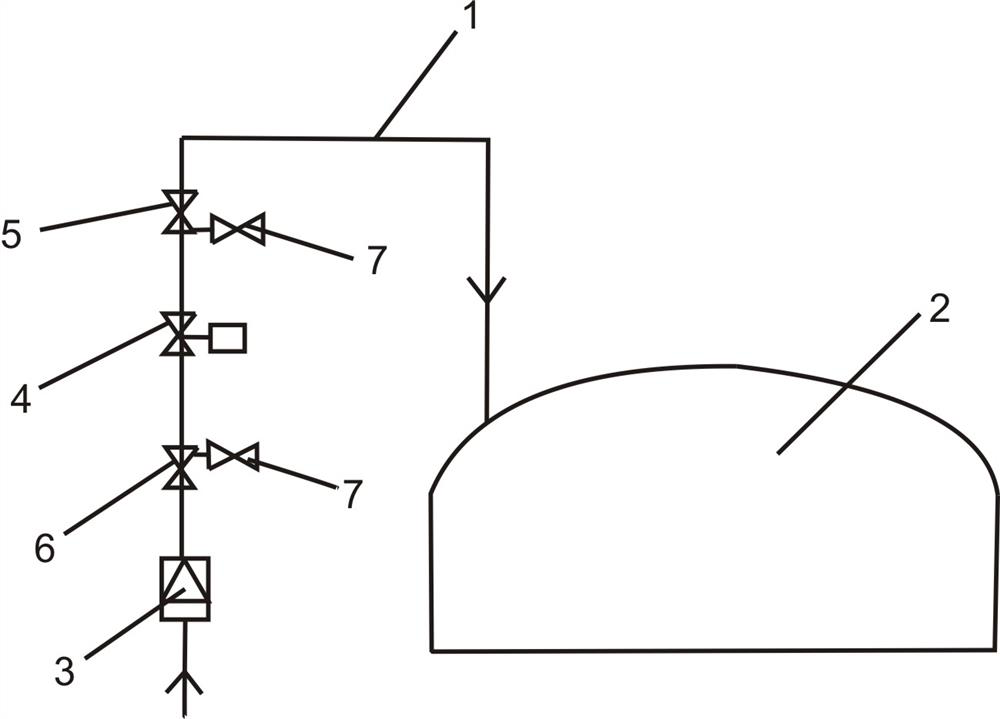

[0038] Step 1: Connect the feeding pipeline 1 directly to the neomycin sulfate fermenter 2, and set a flow meter 3 and a pneumatic diaphragm valve 4 in sequence on the feeding pipeline 1 according to the feeding direction.

[0039] Step 2: Determine the time interval H of each sampling.

[0040] Step 3: every other sampling time interval H, the sampling staff samples the fermented liquid in the neomycin sulfate fermenter 2 to detect indicators such as reducing sugar and ammoniacal nitrogen, and determines the total amount of a sampling time interval H in combination with the metabolism of the fermented liquid. Feeding amount S, calculate the feeding rate V of this sampling time interval, the calculation formula is:

[0041] Feed rate V = total feed volume S / sampling interval H

[0042] S, the unit is L; H, the unit is hour.

[0043] Step 4: If...

Embodiment 2

[0063] After the second branch factory of Three Gorges Pharmaceutical Co., Ltd. adopts the method described in the present invention in the neomycin sulfate fermentation process, the dissolved oxygen in the tank is more stable, the mycelium metabolism is more vigorous, and the biological potency is obviously increased. Metering cup feeding and the second branch factory adopt the method of the present invention to select 3 batches of tanks with the same or close cycle to do comparative experiments. The first branch factory selects fermenter batches F353 / 0696, F356 / 0698, F358 / 0700, and the second branch factory selects The batch numbers of fermenters are F309 / 247, F312 / 248, and F303 / 249. The comparison results are as follows:

[0064] (1) Comparison of dissolved oxygen in the tank: The period of 60h to 84h was selected for the comparison of dissolved oxygen in the experimental tank. At this stage, the metabolism is relatively vigorous, the amount of feed is large, and the fluctua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com