Neutral water-based cleaning agent for cleaning PCB and preparation method of neutral water-based cleaning agent

A PCB board, neutral water technology, applied in the directions of detergent compositions, detergent compounding agents, detergent composition solvents, etc., can solve the problems of PCB board corrosion, toxicity and harm, waste of energy, etc., and achieve good cleaning effect and cleanliness. Good efficiency and improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

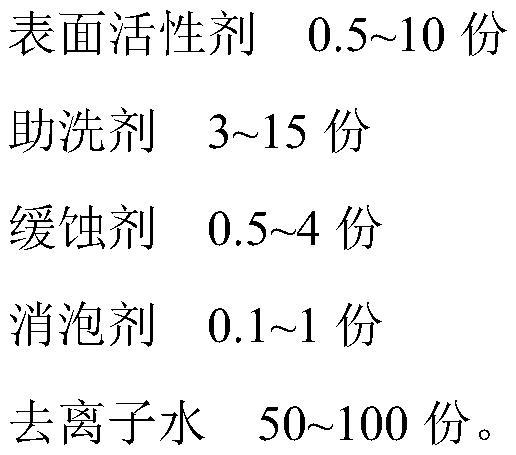

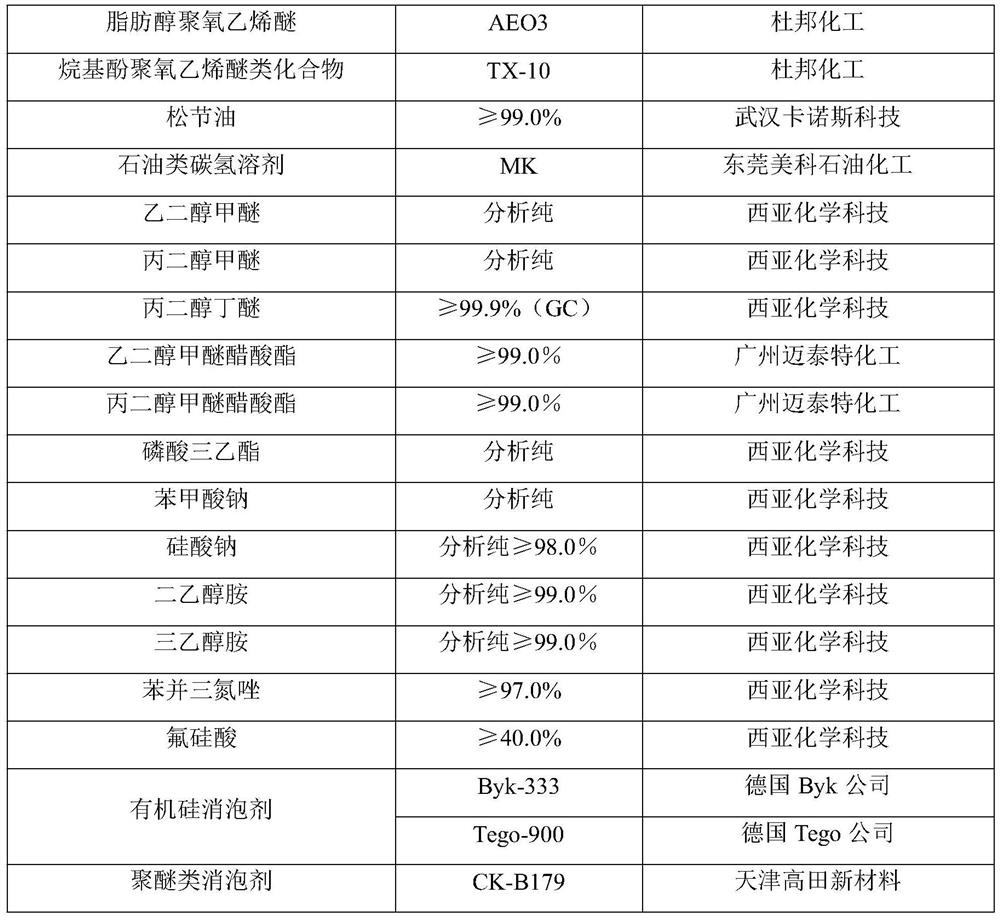

[0040] A neutral water-based cleaning agent for cleaning PCB boards, the dosage of each component is as follows:

[0041]

[0042] Preparation method: add deionized water into the reactor, then put in other raw materials, adjust the pH value to 7.0 after raising the temperature to 40°C, and stir at 800rpm for 15min to obtain the product.

Embodiment 2

[0044] A neutral water-based cleaning agent for cleaning PCB boards, the dosage of each component is as follows:

[0045]

[0046] Preparation method: add deionized water into the reactor, then put in other raw materials, adjust the pH value to 8.0 after raising the temperature to 40°C, and stir at 800rpm for 30min to obtain the product.

Embodiment 3

[0048] A neutral water-based cleaning agent for cleaning PCB boards, the dosage of each component is as follows:

[0049]

[0050] Preparation method: add deionized water into the reactor, then put in other raw materials, adjust the pH value to 7.0 after raising the temperature to 40°C, and stir at 800rpm for 20min to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com