Preparation method of novel solid-solid phase change energy storage material

A phase change energy storage material, a new technology, applied in the field of phase change energy storage material preparation, can solve the problem of high phase change enthalpy, and achieve the effect of meeting the application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

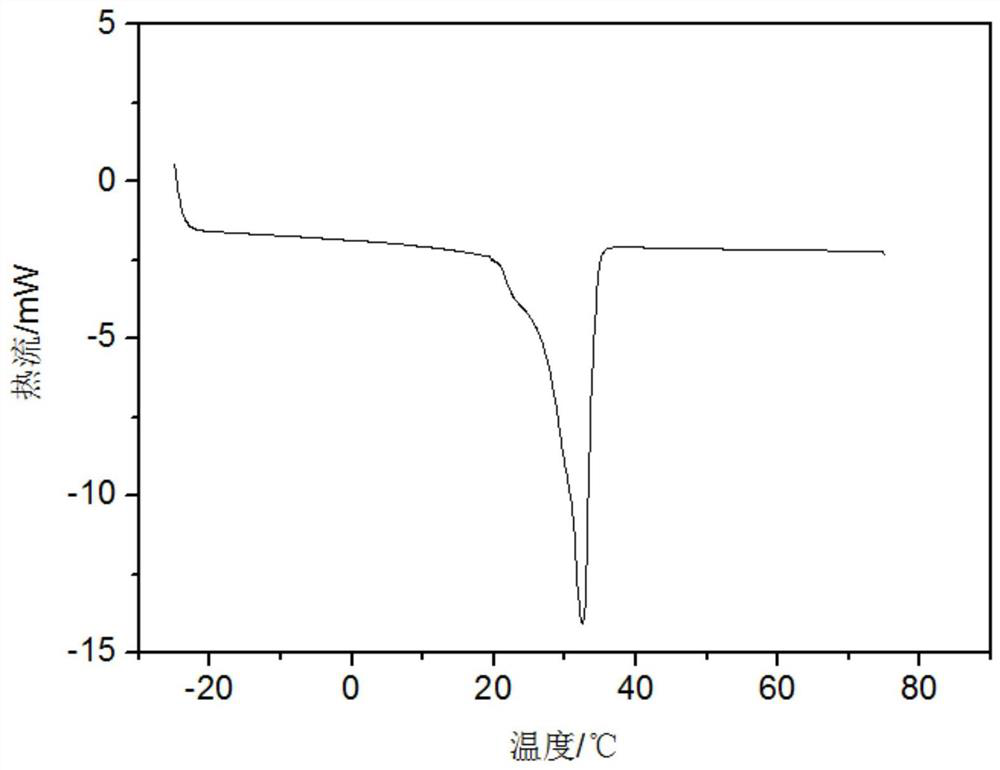

Image

Examples

Embodiment 1

[0032] A method for preparing a novel solid-solid phase change energy storage material, specifically implemented according to the following steps:

[0033] Step 1, add an appropriate amount of polyether polyol into the reactor, and dehydrate under vacuum at 110°C for 2 hours; wherein, the polyether polyol is a compound of polyethylene glycol and polytetrahydrofuran ether glycol, polyethylene glycol and The compounding mass ratio of polytetrahydrofuran ether glycol is 9:1; the molecular weight of polyethylene glycol is 2000, and the molecular weight of polytetrahydrofuran ether glycol is 2000;

[0034] Step 2, lower the temperature of the reactor to 50°C, add an appropriate amount of diisocyanate, keep it warm for 1 hour, then raise the temperature to 80°C, keep it warm for 3 hours, and obtain a polyurethane prepolymer;

[0035] Among them, the diisocyanate is isophorone diisocyanate; the molar ratio of diisocyanate to polyether polyol is 1.3:1;

[0036] Step 3, add an appropr...

Embodiment 2

[0040] A method for preparing a novel solid-solid phase change energy storage material, specifically implemented according to the following steps:

[0041] Step 1, add an appropriate amount of polyether polyol into the reactor, and dehydrate under vacuum at 110°C for 2 hours; wherein, the polyether polyol is a compound of polyethylene glycol and polytetrahydrofuran ether glycol, polyethylene glycol and The compounding mass ratio of polytetrahydrofuran ether glycol is 1:1; the molecular weight of polyethylene glycol is 2000, and the molecular weight of polytetrahydrofuran ether glycol is 2000;

[0042] Step 2, lower the temperature of the reactor to 50°C, add an appropriate amount of diisocyanate, keep it warm for 1 hour, then raise the temperature to 80°C, keep it warm for 2 hours, and obtain a polyurethane prepolymer;

[0043] Among them, the diisocyanate is isophorone diisocyanate; the molar ratio of diisocyanate to polyether polyol is 2:1;

[0044] Step 3, add an appropria...

Embodiment 3

[0048] A method for preparing a novel solid-solid phase change energy storage material, specifically implemented according to the following steps:

[0049] Step 1, add an appropriate amount of polyether polyol into the reactor, and dehydrate under vacuum at 110°C for 2 hours; wherein, the polyether polyol is a compound of polyethylene glycol and polytetrahydrofuran ether glycol, polyethylene glycol and The compounding mass ratio of polytetrahydrofuran ether glycol is 6:1; the molecular weight of polyethylene glycol is 2000, and the molecular weight of polytetrahydrofuran ether glycol is 2000;

[0050] Step 2, lower the temperature of the reactor to 50°C, add an appropriate amount of diisocyanate, keep the temperature for 1 hour, then raise the temperature to 80°C, keep the temperature for 2.5 hours, and obtain the polyurethane prepolymer;

[0051] Among them, the diisocyanate is isophorone diisocyanate; the molar ratio of diisocyanate to polyether polyol is 2:1;

[0052] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com