Method for preparing wall thermal insulation material from industrial solid waste

A technology for thermal insulation material and industrial solid waste, applied in the field of industrial solid waste resource utilization, can solve the problems of difficult industrial solid waste treatment, and achieve the effect of natural pollution-free performance and simple and easy process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

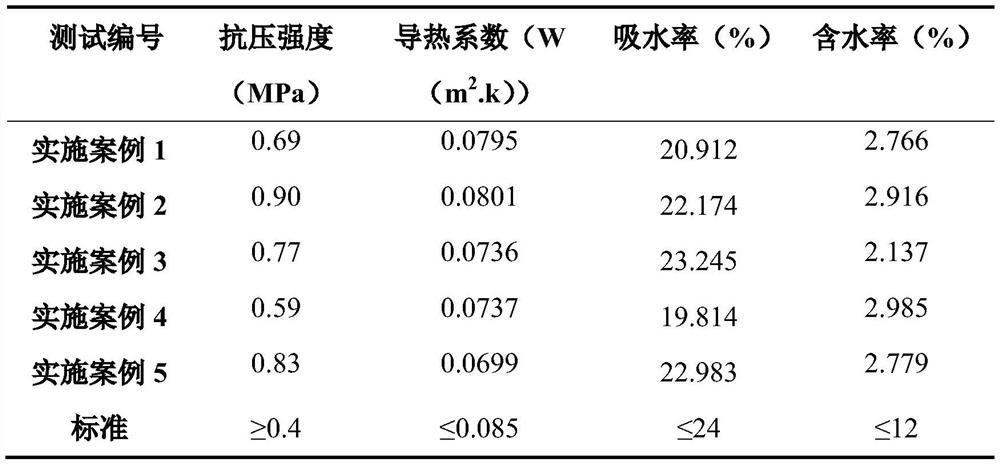

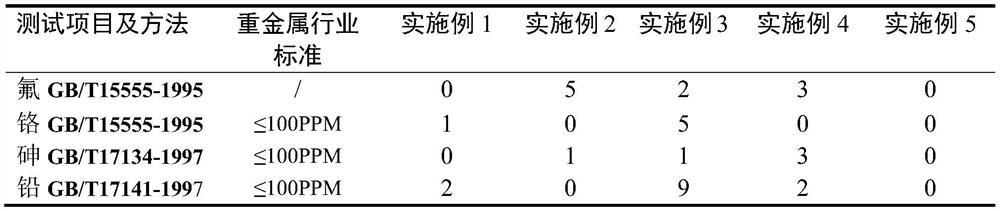

Examples

Embodiment 1

[0028] Embodiment 1: a kind of method utilizing industrial solid waste to prepare wall insulation material, it comprises the following steps,

[0029] Step 1, phosphogypsum, copper slag, and fly ash are dried in a constant temperature drying oven for 12 hours for later use;

[0030] Step 2, grinding, pulverizing and sieving the raw materials to 80 mesh;

[0031] Step 3, add quicklime 5g, add the water of 50mL, make quicklime and water fully react, generate enough Ca(OH) as activator;

[0032] Step 4: Add 200g of phosphogypsum, 10g of copper slag, 50g of fly ash, and mix well;

[0033] Step 5, add 60g of cement again, so that the raw material has gelling properties;

[0034] Step 6. Add 2 g of cement foaming agent, wherein α-olefin sulfonate sodium (AOS): dodecylbenzene sulfonate sodium (LAS): fatty alcohol polyoxyethylene ether sodium sulfate (AES) = 1:1:1 ;

[0035] Step 7. After preparing the slurry, use the semi-dry pressing molding method to pour the mixed raw material...

Embodiment 2

[0039] Embodiment 2: a kind of method utilizing industrial solid waste to prepare wall insulation material, it comprises the following steps,

[0040] Step 1, phosphogypsum, copper slag, and fly ash are dried in a constant temperature drying oven for 12 hours for later use;

[0041] Step 2, grinding, pulverizing and sieving the raw materials to 90 mesh;

[0042] Step 3, add quicklime 7g, add the water of 50mL, make quicklime and water fully react, generate enough Ca(OH) as activator;

[0043] Step 4: Add 200g of phosphogypsum, 15g of copper slag, 50g of fly ash, and mix well;

[0044] Step 5, add 60g of cement again, so that the raw material has gelling properties;

[0045] Step 6. Add 3g of cement foaming agent, wherein α-olefin sulfonate sodium (AOS): dodecylbenzene sulfonate sodium (LAS): fatty alcohol polyoxyethylene ether sodium sulfate (AES) = 1:1:1 ;

[0046] Step 7. After preparing the slurry, use the semi-dry pressing molding method to pour the mixed raw materials...

Embodiment 3

[0050] Embodiment 3: a kind of method utilizing industrial solid waste to prepare wall insulation material, it comprises the following steps,

[0051] Step 1, phosphogypsum, copper slag, and fly ash are dried in a constant temperature drying oven for 12 hours for later use;

[0052] Step 2, grinding, pulverizing and sieving the raw materials to 100 mesh;

[0053] Step 3, add quicklime 12g, add the water of 50mL, make quicklime and water fully react, generate enough Ca(OH) as activator;

[0054] Step 4, add 200g of phosphogypsum, 25g of copper slag, 50g of fly ash, and mix well;

[0055] Step 5, add 60g of cement again, so that the raw material has gelling properties;

[0056] Step 6: Add 4g of cement foaming agent, wherein α-olefin sulfonate sodium (AOS): dodecylbenzene sulfonate sodium (LAS): fatty alcohol polyoxyethylene ether sodium sulfate (AES) = 1:1:1 ;

[0057] Step 7. After preparing the slurry, use the semi-dry pressing molding method to pour the mixed raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com