Coal gangue-containing foundation pit backfill material and preparation method thereof

A technology for coal gangue and foundation pit, which is applied in the field of civil engineering and building materials, can solve problems such as environmental pollution of coal gangue, and achieve the effects of saving construction costs, good use effect and good compressive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

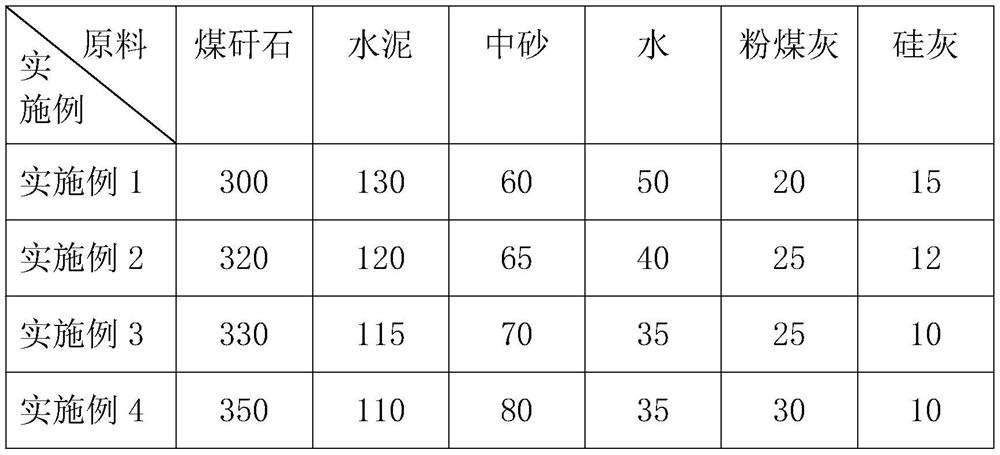

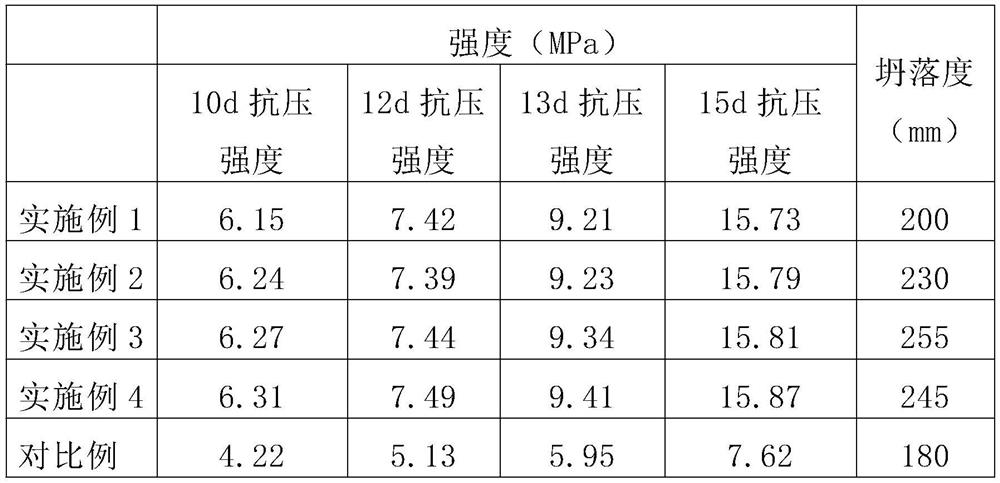

[0028] The foundation pit backfill material containing coal gangue in parts by weight, the specific proportioning in each embodiment is as follows:

[0029]

[0030] Among them, coal gangue is a single gradation with a particle size of 5-10, forming the skeleton structure of the backfill material, and its properties are shown in Table 1.

[0031] Table 1 Physical properties of coal gangue

[0032] Particle size (mm) Compressive performance (MPa) Bulk density (g / cm 3 )

Porosity(%) 5-10 4.2-4.7 1.2-1.8 40-42

[0033] The cement is composite Portland cement, and its strength grade is above 42.5.

[0034] Medium sand is coarse sand with a particle size of 0.5-1mm.

[0035] The water is ordinary tap water.

[0036] Fly ash refers to general fly ash with a particle size between 1 and 100 μm.

[0037] Silica fume is common silica fume whose main chemical composition is amorphous amorphous silicon oxide.

Embodiment 5

[0039] Adopt each raw material in embodiment 1 to prepare the foundation pit backfill material containing coal gangue, and its method may further comprise the steps:

[0040] (1) Take 20 parts of fly ash and 15 parts of silica fume, pour them into a fixed container, add 50 parts of water to dissolve, fully stir to form a mixed solution A;

[0041] (2) Mix 130 parts of cement with the solution A formed in step (1), pour it into the mixing pot, and stir for 60 seconds to form the mixed solution B;

[0042] (3) Fully mix 300 parts of coal gangue and 60 parts of medium sand, weigh half of it and add it to a stirring pot equipped with solution B, and stir for 90 seconds to form mixture C;

[0043] (4) Pour the remaining coal gangue and medium sand into the stirring pot successively, fully stir for 90s, and make the foundation pit backfill material containing coal gangue;

[0044] (5) Pour out the foundation pit backfill material containing coal gangue prepared above from the stirr...

Embodiment 6

[0046] Adopt each raw material in embodiment 2 to prepare the foundation pit backfill material that contains coal gangue, and its method may further comprise the steps:

[0047] (1) Take 25 parts of fly ash and 12 parts of silica fume, pour them into a fixed container, add 40 parts of water to dissolve, fully stir to form a mixed solution A;

[0048] (2) Mix 120 parts of cement and the solution A formed in step (1) evenly, pour into the stirring pot, and stir for 70 seconds to form the mixed solution B;

[0049] (3) Fully mix 320 parts of coal gangue and 65 parts of medium sand, weigh half of it and add it to a stirring pot equipped with solution B, and stir for 80 seconds to form mixture C;

[0050] (4) Pour the remaining coal gangue and medium sand into the stirring pot in turn, fully stir for 100s, and prepare the foundation pit backfill material containing coal gangue;

[0051] (5) Pour out the foundation pit backfill material containing coal gangue prepared above from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com