Modified multi-walled carbon nanotube modified cement-based composite material and preparation method thereof

A technology of multi-wall carbon nanotubes and composite materials, which is applied in the field of modified multi-wall carbon nanotube modified cement-based composite materials and the preparation thereof, can solve the problems of inactive functional groups, difficult to disperse uniformly, restricted dispersion, etc. The method is simple, the raw materials are easy to obtain, and the effect of improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

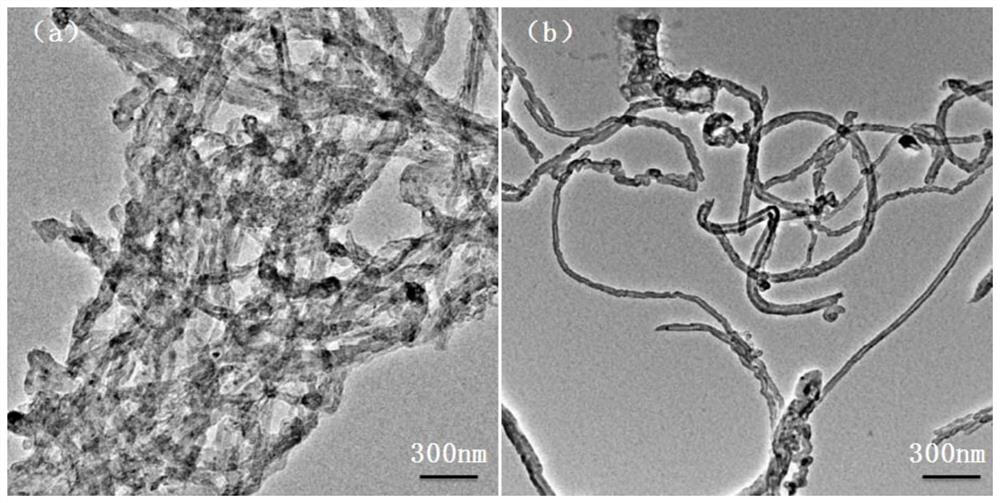

[0031] The preparation method of the modified multi-walled carbon nanotubes is:

[0032] (a) Weigh 1.0 g of multi-walled carbon nanotubes with an aspect ratio of 1800 and a length of 6 μm, place them in 400 mL of 4 mol / L sodium hydroxide solution for ultrasonic dispersion for 25 min, and add 1.5 g of sodium persulfate, mechanically stirred for 6 hours, left to stand and poured off the supernatant, the solids in the lower layer were washed with absolute ethanol and deionized water, and the obtained solids were dried at 80°C to obtain hydroxyl-modified polysaccharides. Walled carbon nanotubes;

[0033] (b) Add the hydroxyl-modified multi-walled carbon nanotubes of step (a) to a 0.8 g / L lauryl polyoxyethylene ether solution, and slowly add 0.3 g of polyamide-amine dendrimers while heating to 50° C. Shaped polymer, reflux reaction for 4h, the solution is stirred and ultrasonic treatment is applied during the reaction process;

[0034] (c) After the reaction, the reaction solutio...

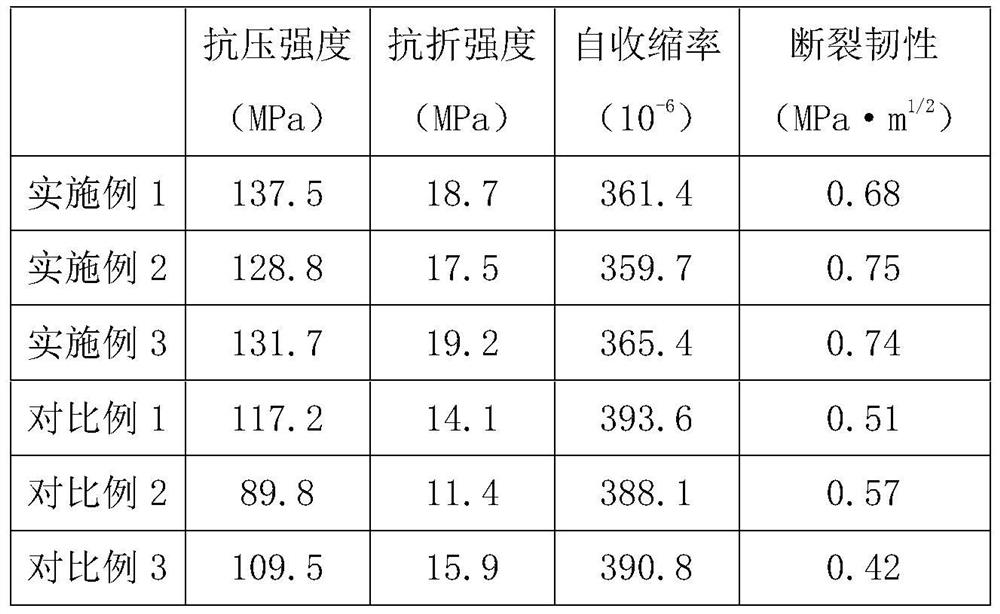

Embodiment 1

[0038]A modified multi-walled carbon nanotube modified cement-based composite material, comprising 24 parts of cement, 60 parts of river sand, 15 parts of silica lime, 5 parts of reinforcing fibers, and 3 parts of modified multi-walled carbon nanotubes in parts by weight , 0.5 parts of polycarboxylate water reducer, 1 part of defoamer, 10 parts of water. The reinforcing fibers are steel fibers, and the aspect ratio of the reinforcing fibers is 25:1. The polycarboxylate water reducer has a solid content of 25% and a water reducing rate of 35%. The defoamer is a silicone defoamer.

[0039] The preparation method of described cement-based composite material, comprises the steps:

[0040] (1) Add the modified multi-walled carbon nanotubes to 3 parts of water under the conditions of stirring and ultrasonic treatment, and finally obtain the modified multi-walled carbon nanotubes that can be uniformly and stably dispersed in water, and then add polycarboxylate-based reducing Water...

Embodiment 2

[0045] A modified multi-walled carbon nanotube modified cement-based composite material, comprising 30 parts of cement, 90 parts of river sand, 30 parts of silica lime, 10 parts of reinforcing fibers, and 5 parts of modified multi-walled carbon nanotubes in parts by weight , 1.5 parts of polycarboxylate water reducer, 2 parts of defoamer, 15 parts of water. The reinforcing fiber is glass fiber, and the aspect ratio of the reinforcing fiber is 40:1. The polycarboxylate water reducer has a solid content of 45% and a water reducing rate of 50%. The defoamer is a silicone defoamer.

[0046] The preparation method of described cement-based composite material, comprises the steps:

[0047] (1) Add the modified multi-walled carbon nanotubes to 3 parts of water under the conditions of stirring and ultrasonic treatment, and finally obtain the modified multi-walled carbon nanotubes that can be uniformly and stably dispersed in water, and then add polycarboxylate-based reducing Water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com