High-salinity wastewater flash evaporation and concentration system coupled with solar heat collection

A technology that couples solar energy and high-salt wastewater, and is used in general water supply conservation, heating water/sewage treatment, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

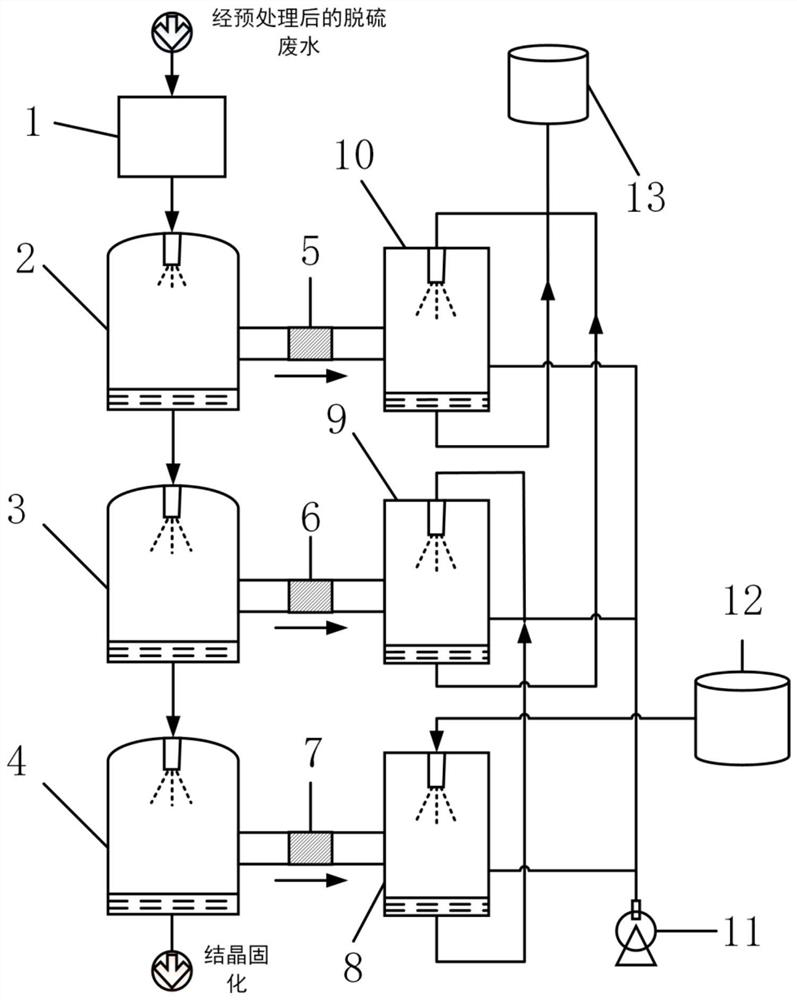

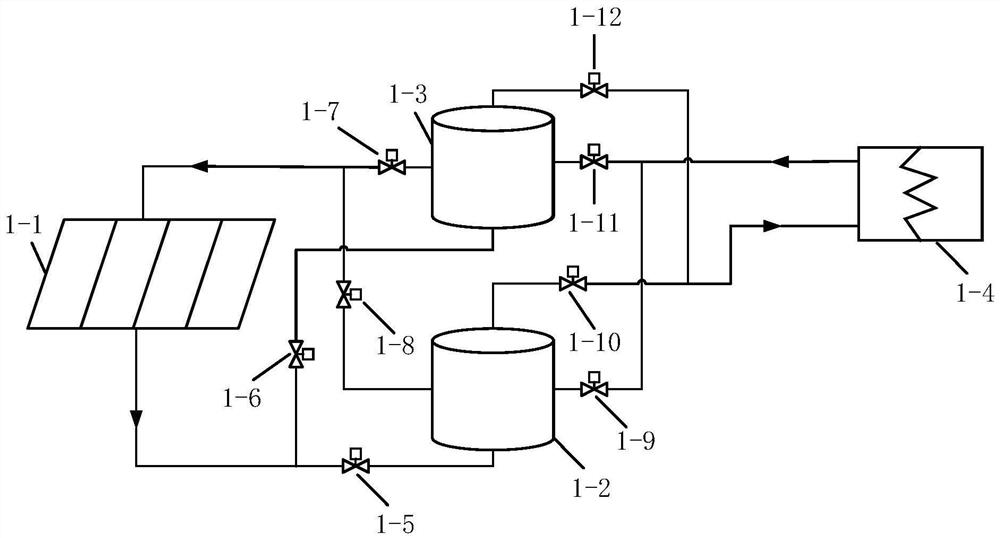

[0014] refer to figure 1 , a high-salt wastewater concentration system coupled with solar heat collection of the present invention, comprising: a wastewater preheating system 1, a first-stage flash chamber 2, a second-stage flash chamber 3, a third-stage flash chamber 4, and a first defogging chamber Device 5, the second demister 6, the third demister 7, the primary condensing chamber 8, the secondary condensing chamber 9, the tertiary condensing chamber 10, the vacuum pump 11, the condensed water tank 12, the fresh water tank 13, the waste water The preheating system 1 is connected to the primary flash chamber 2 through pipelines, and the wastewater solution heated by the wastewater preheating system 1 is injected into the primary flash chamber 2 from the nozzle 2-1 in the primary flash chamber 2. A pressure measurement component 2-2 is arranged in the flash chamber, and the pressure measurement component 2-2 is connected with a data collector. The primary flash chamber 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com