Warehouse-in and warehouse-out management guiding system for steel pipe warehouse, and ground rail type patrol robot

A rail-type, robotic technology, applied in the field of warehouse management, can solve the problems of inconsistent database inventory and actual situation, personnel operation errors, high labor intensity, etc., to reduce labor intensity, reduce weight, and improve the degree of intelligence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

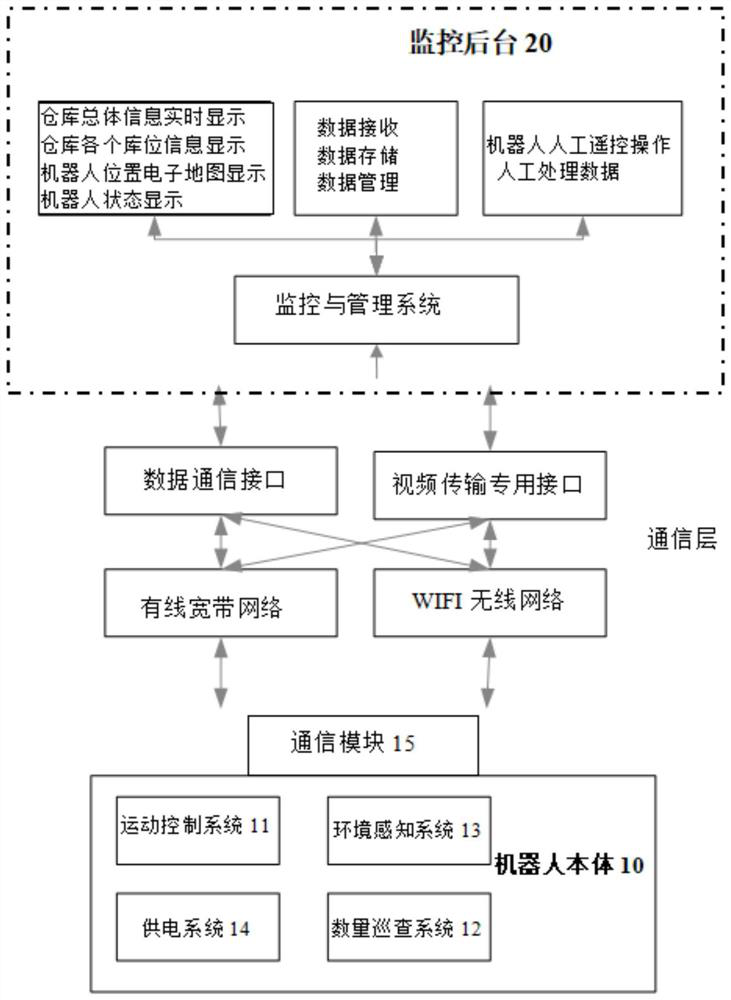

[0045] Such as figure 1 Shown is an overall frame diagram of a ground rail-type inspection robot in a preferred embodiment of the present invention. Such as figure 1 As shown, the ground-orbit inspection robot includes a robot body 10 and a monitoring background 20; the robot body 10 exchanges data with the monitoring background 20 through its own communication module and communication layer. The communication layer includes a communication interface capable of wireless / wired communication with the communication module of the robot body 10, a wired broadband network, a wifi wireless network, and a dedicated interface for video transmission. The monitoring background 20 comprises a monitoring host computer (monitoring and management software system is installed), and the monitoring host computer is provided with an instruction input terminal (for manual processing of data and manual remote operation of the robot body), a display (for real-time display of warehouse overall info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com