Automatic cutting pick machining and welding device of coal mining machine

A technology of automatic processing and welding device, applied in the field of picks, can solve the problems of slow welding speed, inconvenient welding parts, air quality damage, etc., and achieve the effect of improving welding speed, stable and fast limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

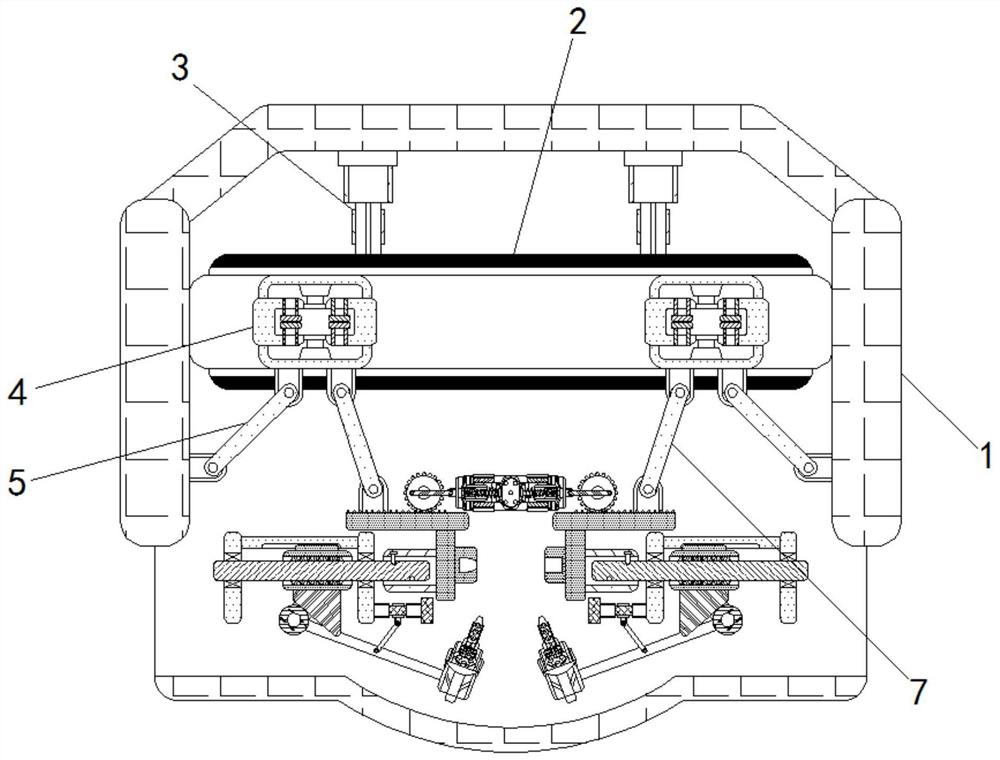

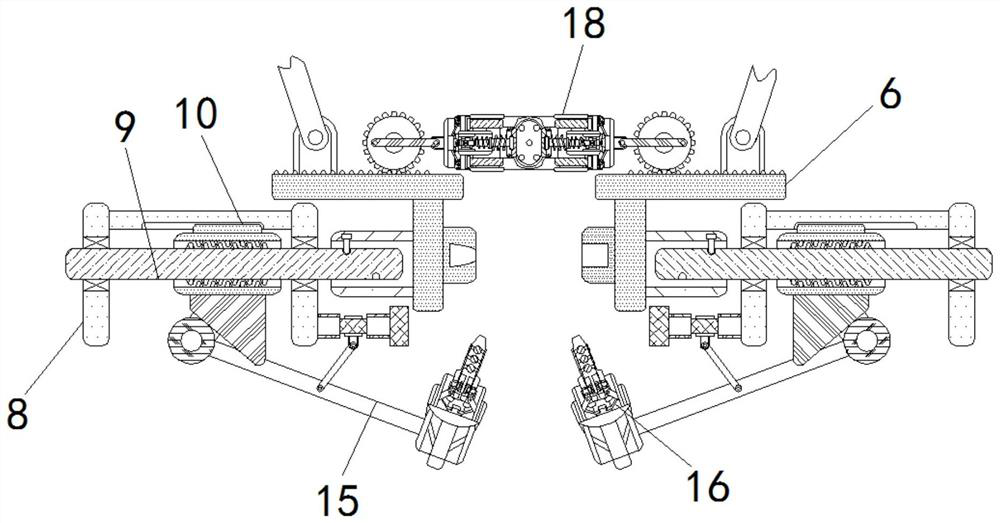

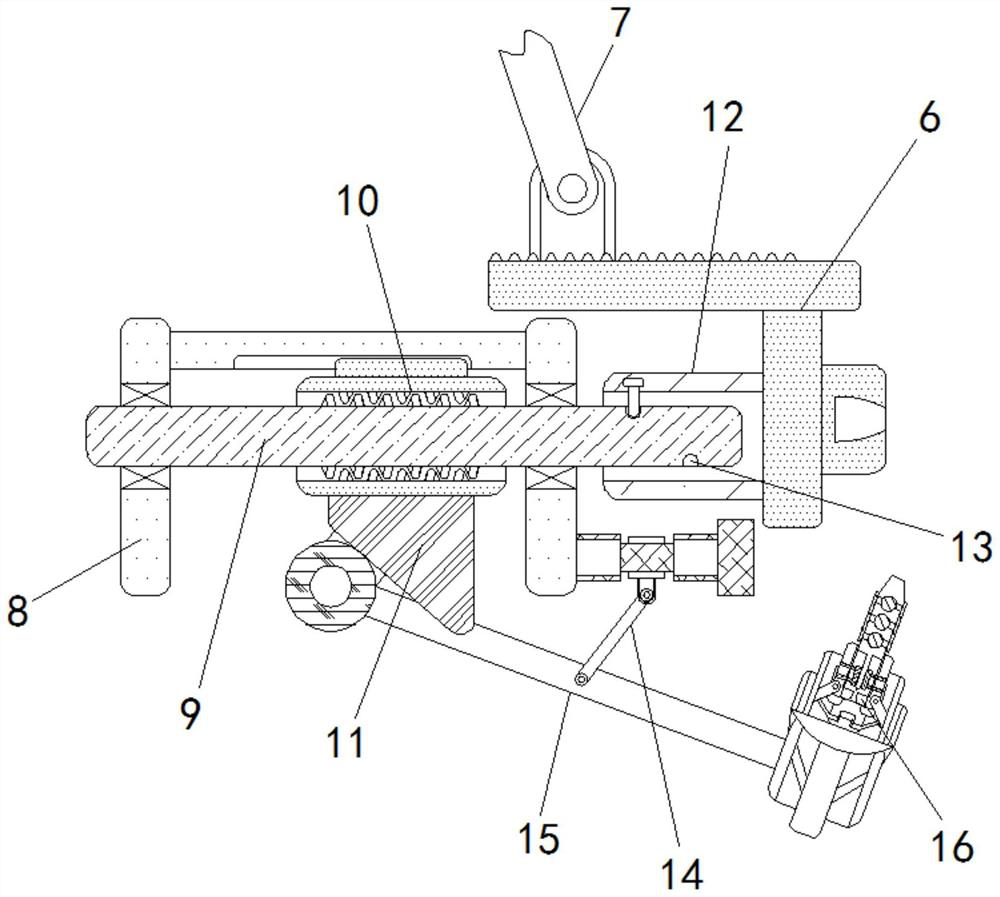

[0022] See Figure 1-4 , A coal-proof automatic processing welding device, including the housing 1, and the upper portion of the inner chamber of the housing 1, and the movable frame 2, the movable block 2 and the end wall of the inner cavity of the housing 1 are fixed. The expansion column 3, the inner cavity of the movable frame 2 slides a symmetrical movable member 4, and the movable member 4 and the inner cavity side wall of the casing 1 are movable between the connecting rod 5, and the lower portion of the inner cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com