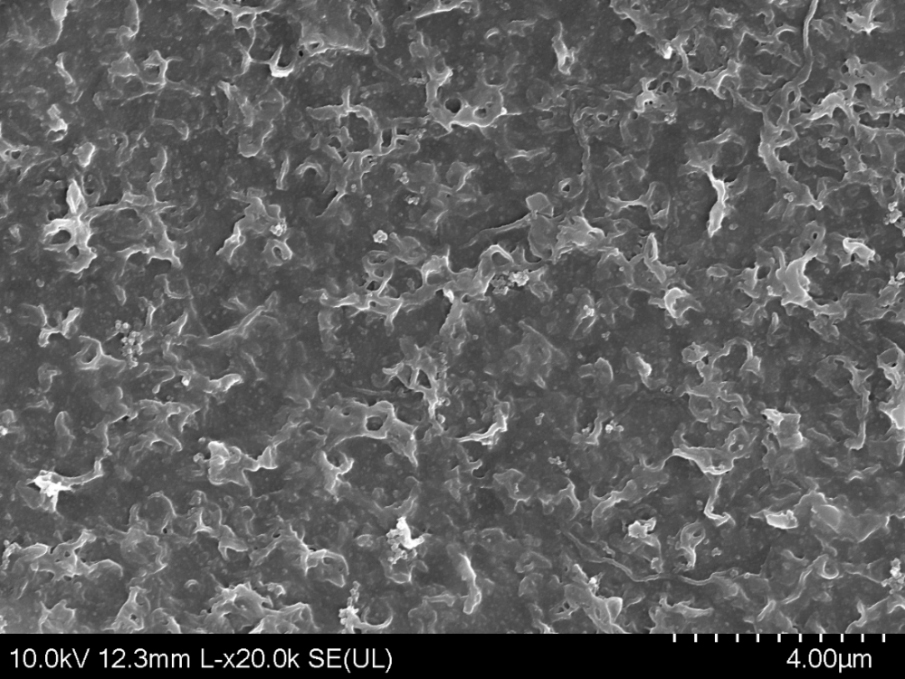

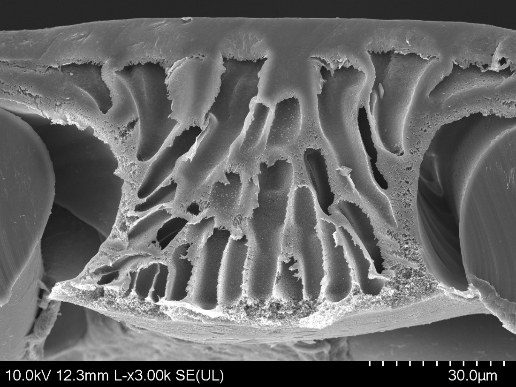

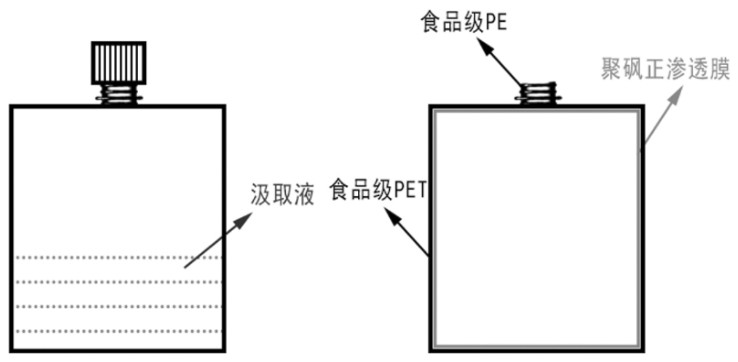

Dopamine and polyvinyl alcohol compounded modified polysulfone forward osmosis membrane as well as preparation method and application thereof

A technology of polyvinyl alcohol and compound modification, applied in the field of membrane separation, can solve the problems of no water available, complicated equipment, and inability to apply emergency rescue, etc., and achieve the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step (1): Add polysulfone particles with a mass percentage of 12 to N,N-dimethylformamide, N-methylpyrrolidone and acrylic acid solvent, stir and fully dissolve at 80°C, and continue stirring for 10 hours , and then let it stand for more than 2 hours to completely defoam, and then the prepared casting solution is ready for use;

[0031] Step (2): Coat the casting solution prepared in step (1) on the polyester screen that has been soaked and pretreated in N,N-dimethylformamide, and scrape it evenly on the non-woven fabric with a scraper. Form the bottom film layer on the cloth and leave it in the air for 10 seconds, then put the bottom film layer into the gel bath to form a bottom layer with a porous structure through phase inversion gel, the composition of the gel bath is deionized water, The gel bath time is 10 minutes. After the solvent is completely removed, put it into deionized water and save it for later use;

[0032] Step (3): Immerse the porous bottom layer pre...

Embodiment 2

[0036] Step (1): Add polysulfone particles with a mass percentage of 14 to a solvent consisting of N,N-dimethylformamide and N-methylpyrrolidone, stir and fully dissolve at 80°C, continue stirring for 8 hours, and then Leave it to stand for more than 2 hours to make it completely defoamed, and then the prepared casting solution is obtained and set aside;

[0037] Step (2): Coat the casting solution prepared in step (1) on the polyester screen that has been soaked and pretreated in N,N-dimethylformamide, and scrape it evenly on the non-woven fabric with a scraper. Form the bottom film layer on the cloth and leave it in the air for 10 seconds, then put the bottom film layer into the gel bath to form a bottom layer with a porous structure through phase inversion gel, the composition of the gel bath is deionized water, The gel bath time is 10 minutes. After the solvent is completely removed, put it into deionized water and save it for later use;

[0038] Step (3): Immerse the por...

Embodiment 3

[0043] Step (1): Add polysulfone particles with a mass percentage of 12 to a solvent consisting of N,N-dimethylformamide and N-methylpyrrolidone, stir and fully dissolve at 80°C, continue stirring for 10 hours, and then Leave it to stand for more than 2 hours to make it completely defoamed, and then the prepared casting solution is obtained and set aside;

[0044]Step (2): Coat the casting solution prepared in step (1) on the polyester screen that has been soaked and pretreated in N,N-dimethylformamide, and scrape it evenly on the non-woven fabric with a scraper. Form the bottom film layer on the cloth and leave it in the air for 10 seconds, then put the bottom film layer into the gel bath to form a bottom layer with a porous structure through phase inversion gel, the composition of the gel bath is deionized water, The gel bath time is 10 minutes. After the solvent is completely removed, put it into deionized water and save it for later use;

[0045] Step (3): Immerse the por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com