Anti-winding cleaning rolling brush and cleaning robot

An anti-winding and rolling brush technology, applied in cleaning machinery, robot cleaning machines, cleaning equipment, etc., can solve the problems of affecting the cleaning effect of cleaning robots, time-consuming and laborious, easy to wind up hair, etc., to save weight, reduce weight, reduce The effect of hard work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

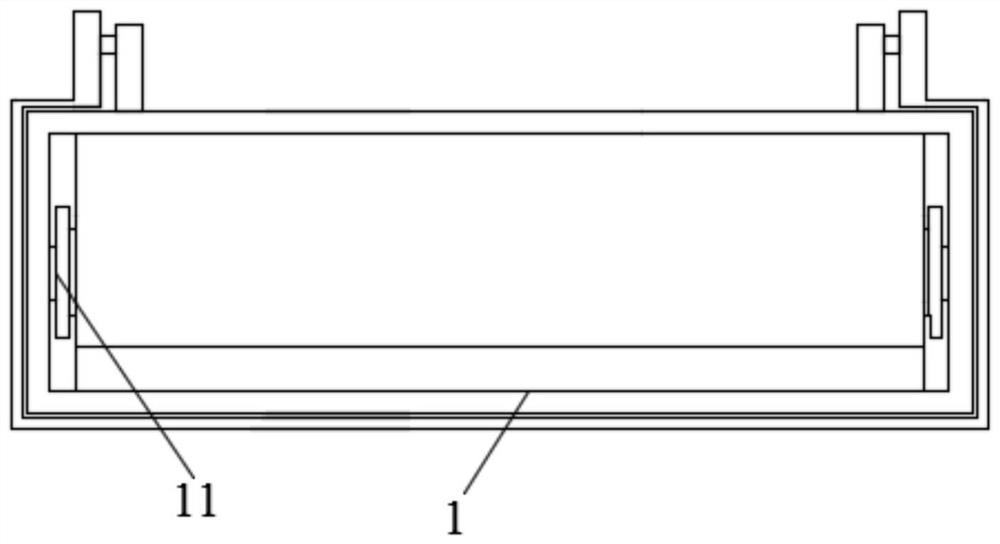

[0057] Such as figure 1 as shown, figure 1 It is a schematic diagram of the structure of the roller brush holder.

[0058] The anti-winding cleaning roller brush of the present invention can be arranged on the roller brush frame 1, and the roller brush frame 1 includes a roller brush installation groove 11 respectively arranged on one end of the roller brush frame 1 in the length direction, and a roller brush transmission groove 11 at the other end. The roller brush transmission groove is a polygonal or star-shaped roller brush transmission groove. The roller brush transmission groove is connected with the motor, and is used for torque-transmittable connection with the anti-winding cleaning roller brush. The roller brush mounting groove 11 can be a complete cylindrical roller brush mounting groove 11 formed by two semi-cylindrical grooves fastened together, for installing an anti-winding cleaning roller brush, for example, there is a semi-cylindrical groove on the roller brus...

Embodiment 2

[0088] Such as Figure 5 as shown, Figure 5 It is a structural schematic diagram of the cleaning robot of the present invention.

[0089] The present invention further provides a cleaning robot, comprising an anti-winding cleaning roller brush and a machine base, and the anti-winding cleaning roller brush is rotatably arranged on the machine base. details as follows:

[0090] The machine base, which can be a circular or D-shaped machine base;

[0091] The rolling brush frame 1, the rolling brush frame 1 is the rolling brush frame 1 in the above-mentioned embodiment, the rolling brush frame 1 is arranged on the bottom of the machine base, specifically, the rolling brush frame 1 can be located in the walking wheel set at the bottom The first half of the axis can also be located at the bottom and the second half of the central axis of the walking wheel set; the roller brush holder 1 can be floatingly arranged on the bottom of the housing; the roller brush holder 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com