Liquid food pulping device for food production and processing

A liquid food and food technology, which is applied in applications, kitchen utensils, household utensils, etc., can solve the problems of low preparation efficiency and inability to make food into slurry, and achieve good crushing effect, simple structure, and better crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

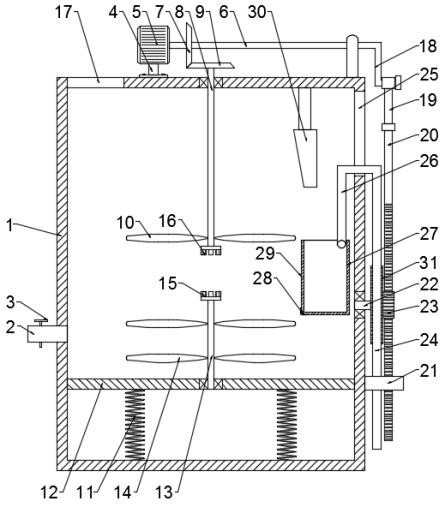

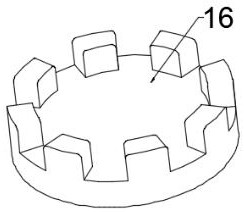

[0025] Example 1: Please refer to Figure 1-3 , a liquid food pulping device for food production and processing, comprising a preparation box 1, a discharge pipe 2 is fixedly connected to the left side of the preparation box 1, a valve 3 is arranged in the middle of the discharge pipe 2, and a motor bracket 4 is fixedly connected to the top of the preparation box 1 A motor 5 is fixedly connected to the top of the motor bracket 4, and the output end of the motor 5 is fixedly connected to a driving rotating rod 6, and the outer side of the driving rotating rod 6 is fixedly connected to a driving bevel gear 7, and the top of the preparation box 1 is rotatably connected to a longitudinal rotating shaft 8, and The top of the rotating shaft 8 is fixedly connected with a driven bevel gear 9, the driving bevel gear 7 is meshed with the driven bevel gear 9, and the outer side of the lower end of the longitudinal rotating shaft 8 is fixedly connected with a first crushing blade 10;

[0...

Embodiment 2

[0038] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the first crushing blade 10 and the second crushing blade 14 are not spiral blades, and the spiral first crushing blade 10 and the second crushing blade are flat 14 It can promote the flow of materials and speed up the crushing efficiency.

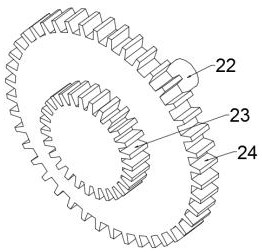

[0039] The working principle of the present invention is: when using, add raw materials into the device, turn on the motor 5, the rotation of the motor 5 drives the driving bevel gear 7 to rotate, the rotation of the driving bevel gear 7 drives the rotation of the driven bevel gear 9, and then drives the rotation of the vertical shaft 8, and the vertical The rotating shaft 8 drives the first pulverizing blade to rotate to realize pulverization, and simultaneously the crankshaft 18 drives the transmission rack 20 to move up and down through the transmission rod 19, and the transmission rack 20 synchronously drives the driven rack 24 to move up and down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com