USB data transmission connector assembling and packaging equipment and assembling and packaging process

A technology of data transmission and packaging equipment, applied in the directions of transportation packaging, transportation and packaging, packaging, etc., can solve the problems of increasing cutting steps, increasing the complexity of the control system of the cutting mechanism, and reducing the cutting efficiency of the casing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

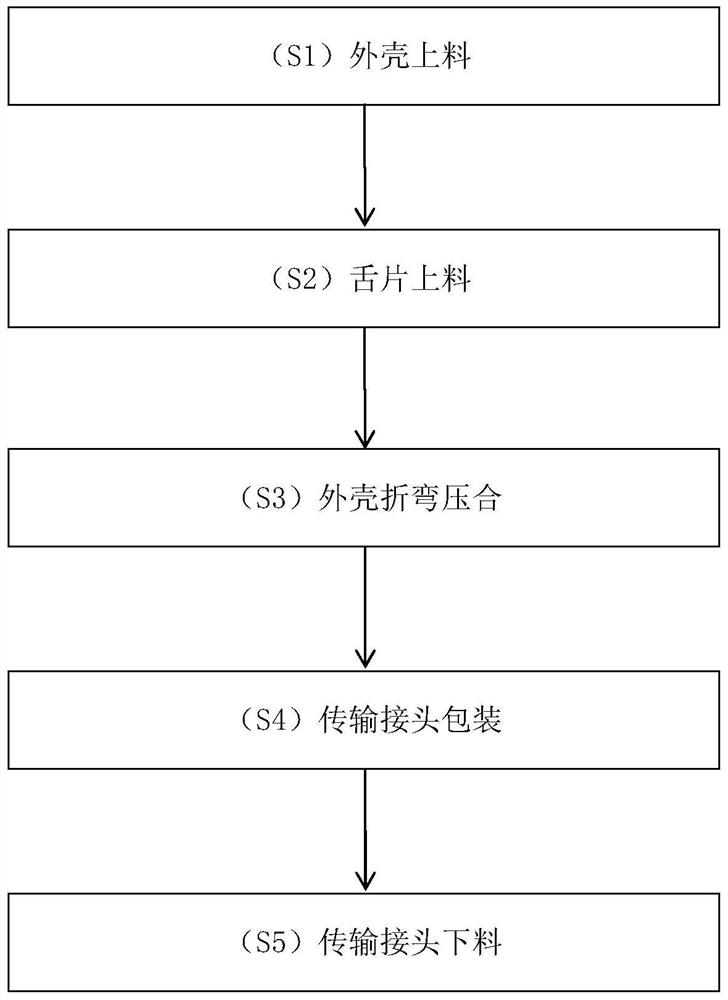

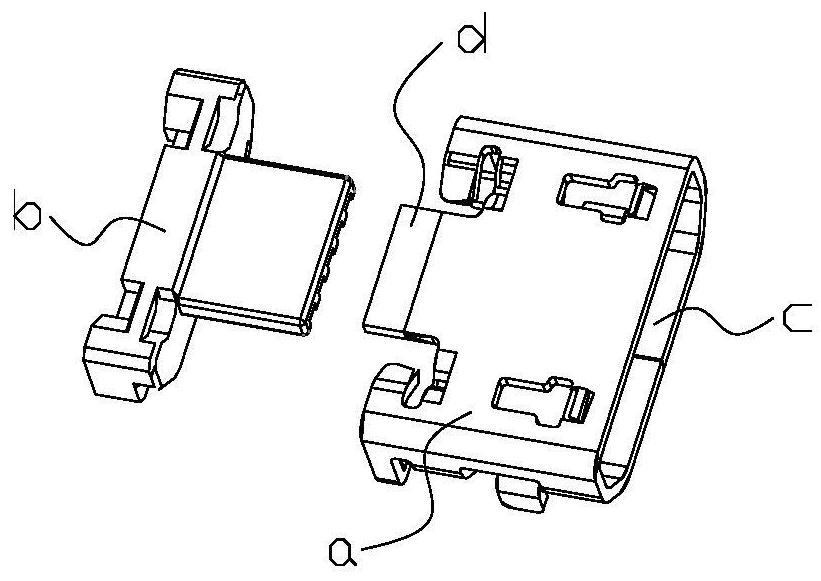

[0038] Such as Figure 1-21 A USB data transmission joint assembly and packaging equipment is shown, the equipment includes a workbench and an assembly device 1 and a packaging device 2 fixed on the workbench; the input end of the assembly device 1 is connected to the shell feeding station and the tongue feed respectively The stations are connected, the output end of the assembly device 1 is connected with the input end of the packaging device 2; the input end of the packaging device 2 is connected with the carrier tape feeding station, and the output end of the packaging device 2 is connected with the unloading station; the assembly device 1 is used for USB Assembling of the data transmission connector; the packaging device 2 is used for packaging the assembled USB data transmission connector into a carrier tape.

[0039] The product flow direction of the USB data transmission connector is: assembly device 1 to packaging device 2 .

[0040] Such as figure 2 Shown is a sche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com