Water-rich sand layer shield interval contact channel stratum pre-reinforcement structure and method

A technology of communication channel and water-rich sand layer, which is applied in the direction of tunnel, earthwork drilling, tunnel lining, etc., can solve the problems that the construction period cannot be effectively guaranteed, safety accidents are prone to occur, and construction safety risks are large, so as to ensure the quality of reinforcement And connection effect, enhanced reinforcement effect, good effect of reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

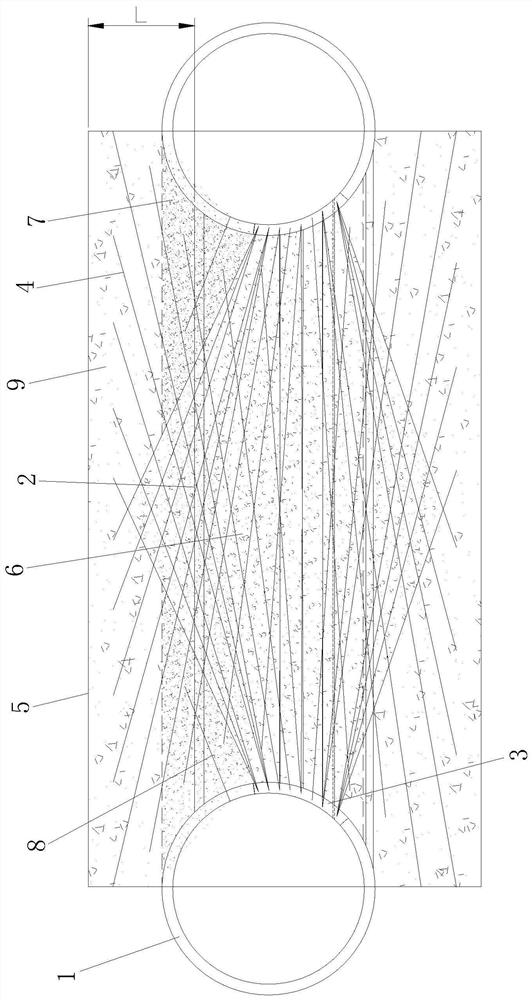

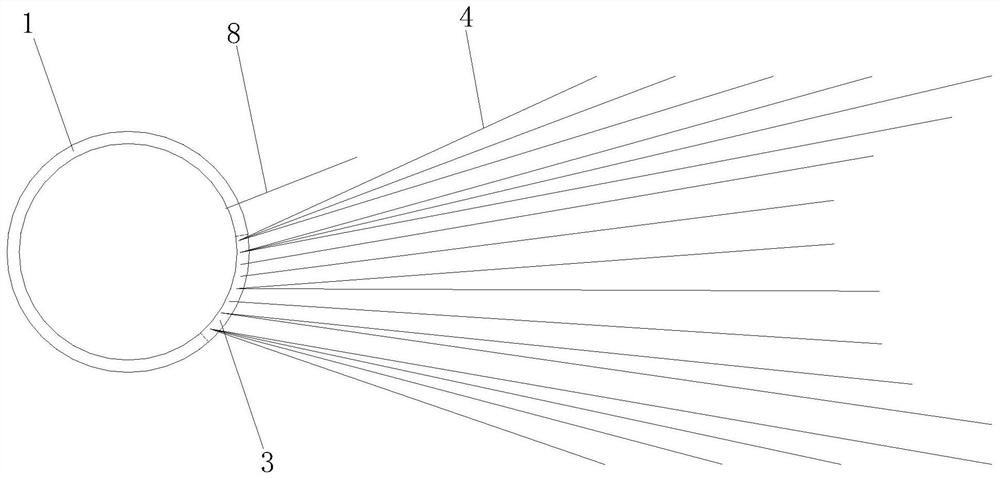

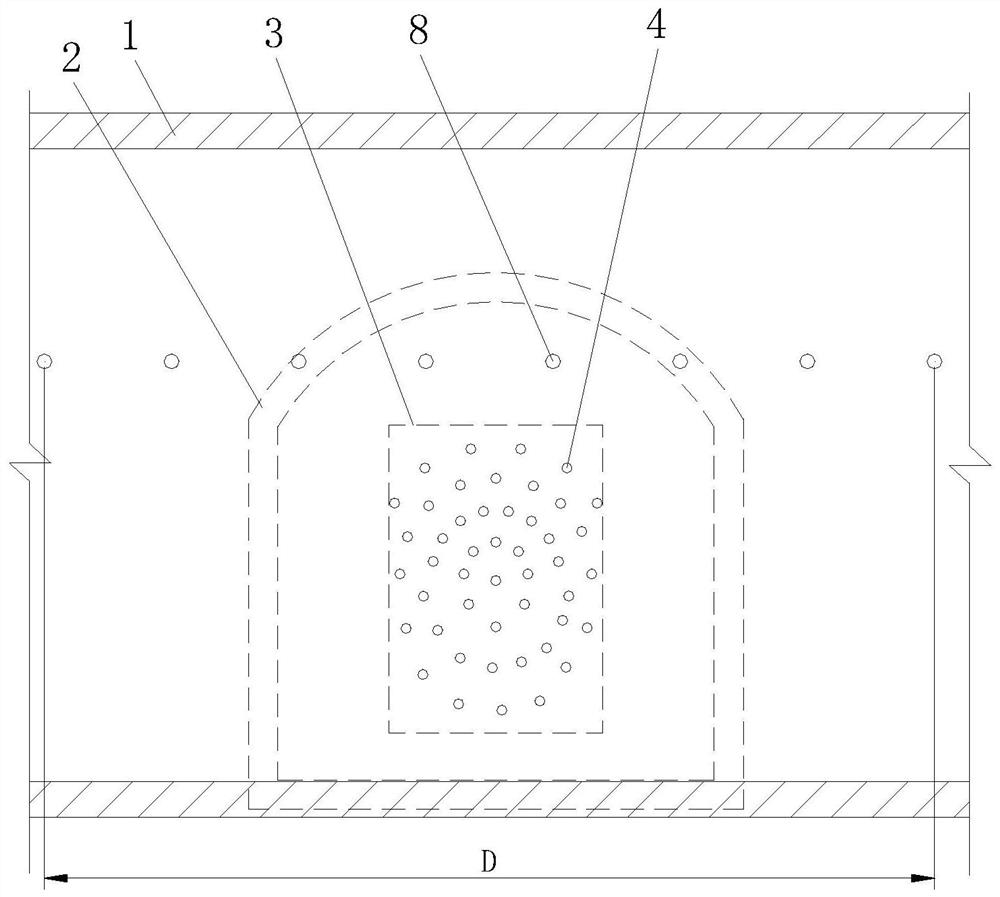

[0052] like Figure 1 to Figure 3 The shown pre-strengthening structure of the connection channel stratum in the shield tunnel interval of the water-rich sand layer includes an overall reinforcement structure of the channel stratum for reinforcing the stratum in the area where the communication channel 2 is constructed, and two front and rear sections of the communication channel 2 to be constructed, respectively. The channel end stratum reinforcement structure is reinforced by the end stratum, and the two channel end stratum reinforcement structures are respectively located on the front and rear sides of the channel stratum integral reinforcement structure, and both of them are fastened and connected to the channel stratum integral reinforcement structure as follows: One body; the constructed communication channel 2 is an undercut tunnel connected between the two shield tunnels 1 and the tunnel body is located in the water-rich sand layer;

[0053] The ground reinforcement st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com