Construction method for bailing out stuck single-shield tunnel boring machine

A construction method and single-shield technology, applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problems of inconvenient construction in front of the cutter head, increased construction difficulty, increased risk factor, etc., to save cost and time, Fewer construction steps, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

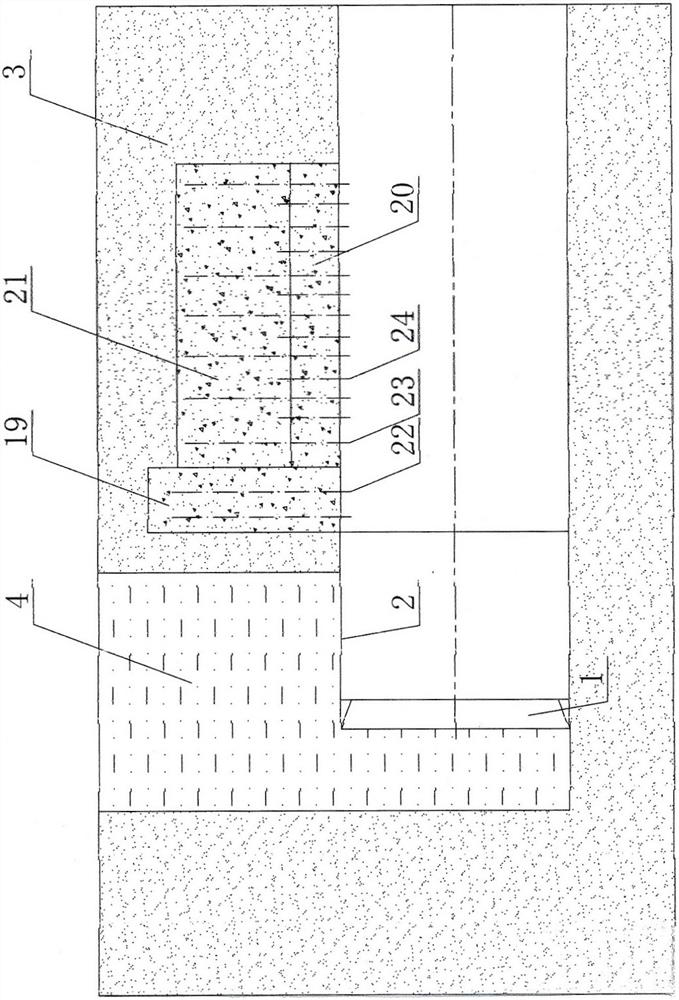

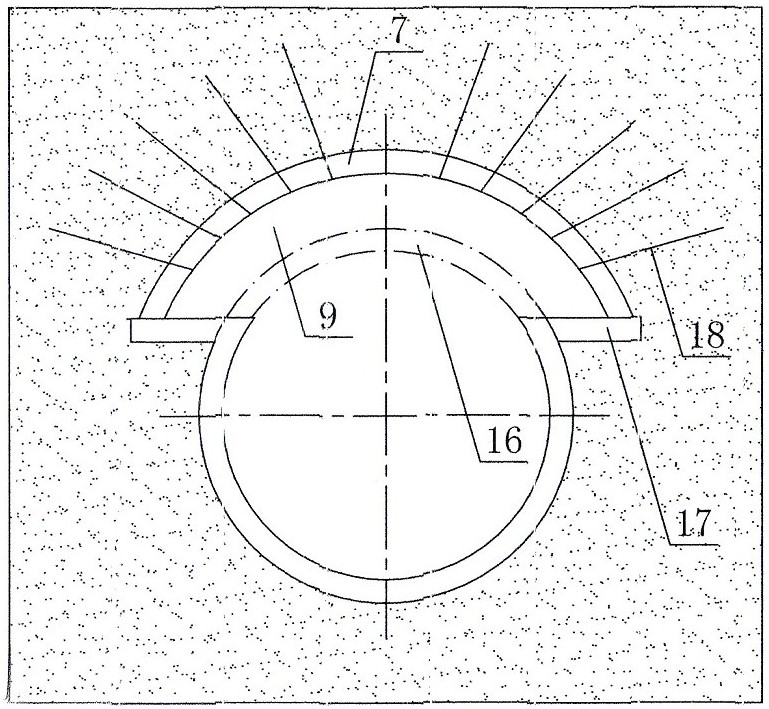

[0024] Embodiment 1: as figure 1 , 2 , 3, and 4, including the following steps:

[0025] 1. Arrange hollow anchor pipe grouting behind the shield to consolidate the surrounding rock in the operation area;

[0026] 2. Expand the excavation and replace the arch support in the working area of the pipe shed drilling rig;

[0027] 3. Build an advanced pipe shed to the front of the tunnel face and the area affected by the landslide;

[0028] 4. Excavate pilot holes on both sides of the left and right shields;

[0029] 5. Manually clean the slag accumulated in the landslide area in front of the cutter head in the cutter head and through the guide holes on both sides;

[0030] 6. Clean up the collapsed debris in front of the cutter head until the cutter head can rotate normally, and the TBM can solve the problem; step 4 can be operated simultaneously with steps 1, 2 and 3.

[0031] Wherein, in the first step, its specific operation is as follows: the first hollow anchor pipe 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com