Hydraulic reverse formwork construction method for light aluminum alloy formwork of square chimney

An aluminum alloy formwork and chimney technology, which is applied to formwork/formwork/work frame, building type, and on-site preparation of building components, etc., can solve the problem of slip marks on the surface of the cylinder wall, drift and torsion of the platform, and easy cracking of the concrete surface. and other problems, to achieve the effect of convenient construction, improved safety, and excellent appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below, but the implementation scope of the present invention is not limited to the following embodiments.

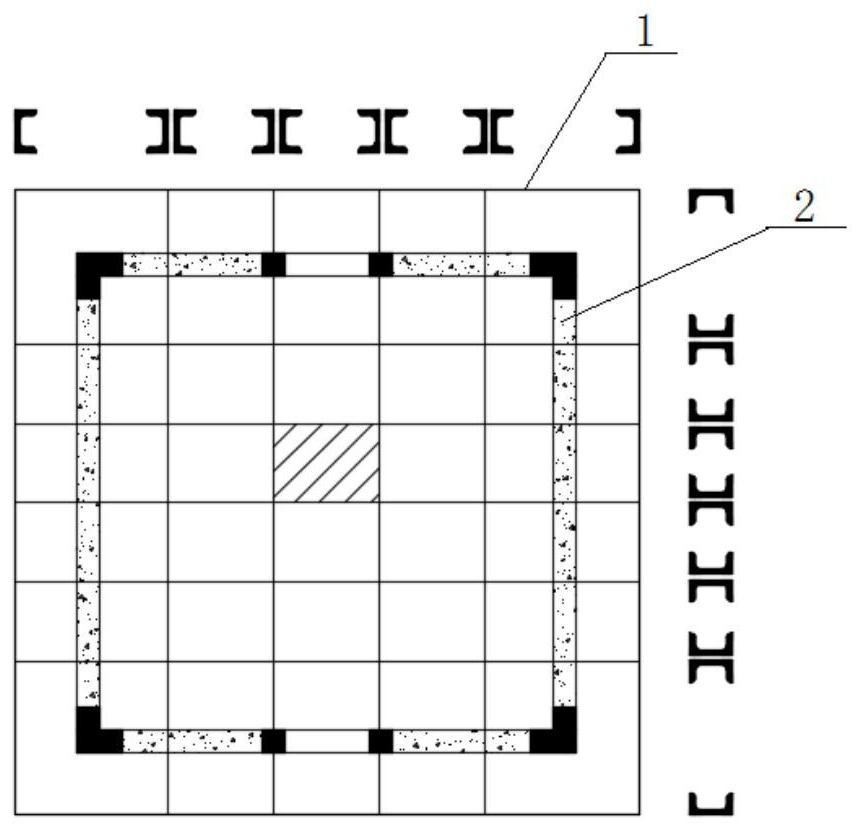

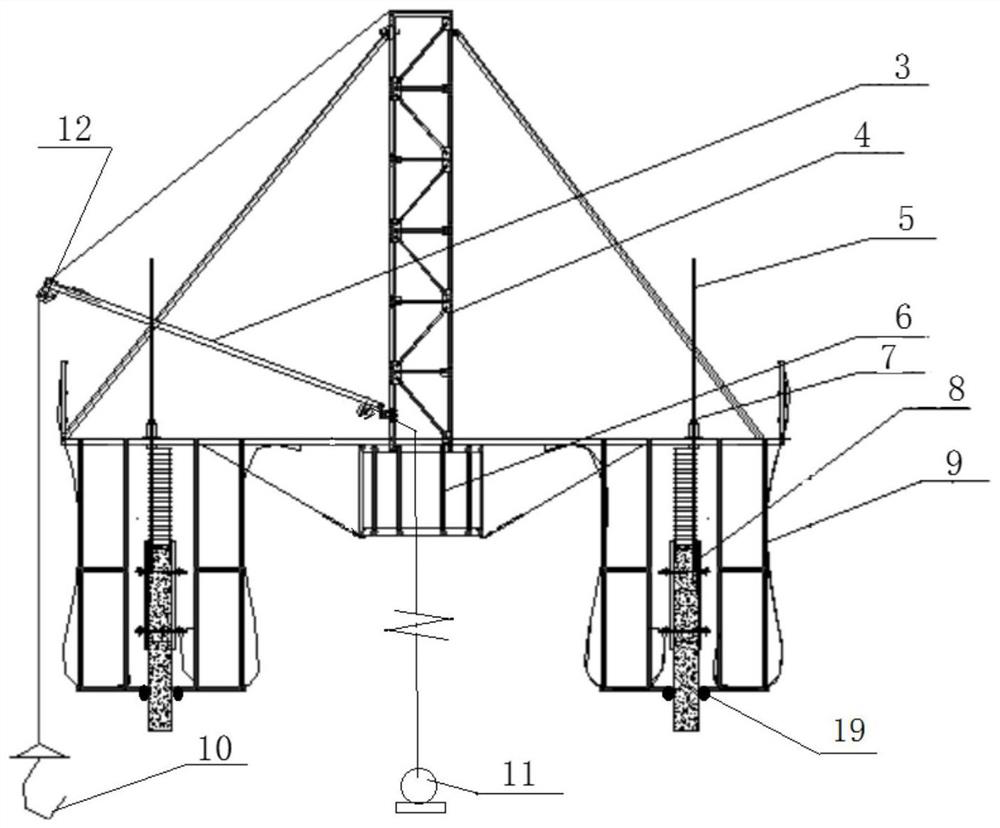

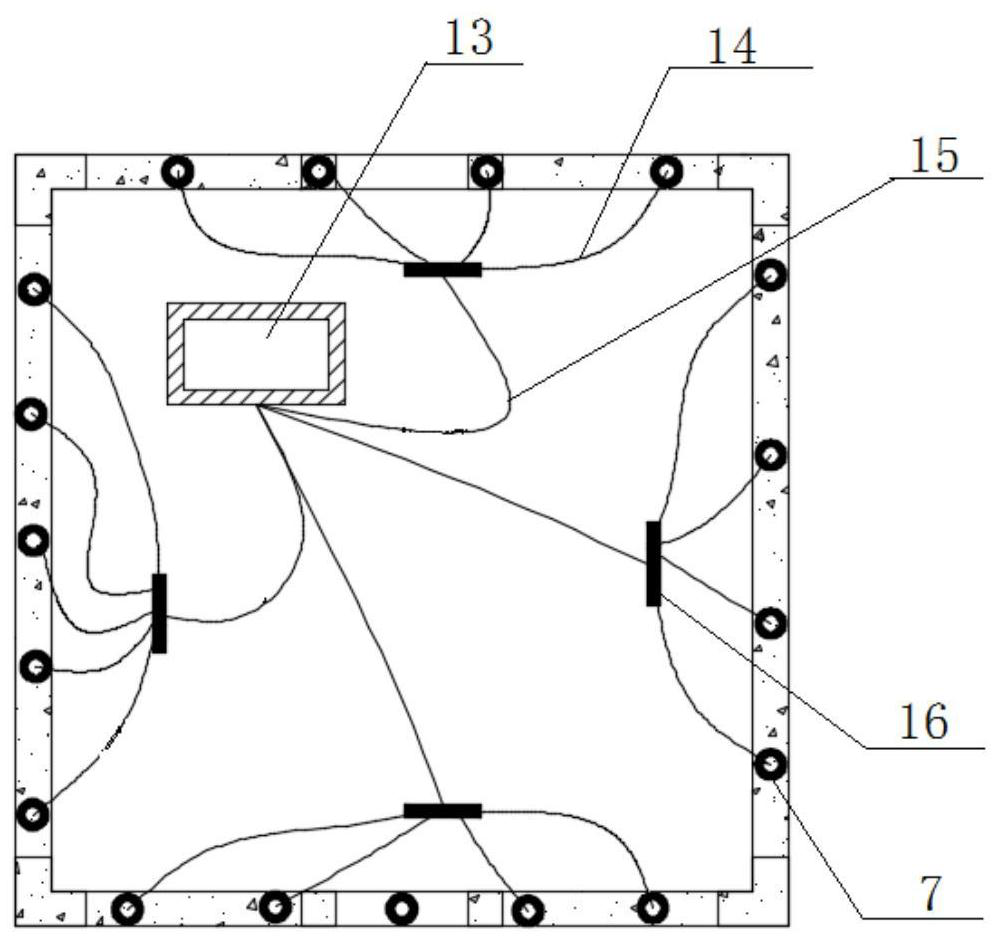

[0028] Such as Figure 1-Figure 5 As shown, a square chimney light aluminum alloy formwork hydraulic inversion construction method uses light aluminum alloy formwork and uses hydraulic inversion to lift the construction truss, specifically including:

[0029] After the wall construction and earthwork backfilling are completed, the light aluminum alloy formwork hydraulic pouring equipment will be assembled. See Figure 5 First set up a temporary installation platform 21, bind 2.5 meters high steel bars 20, support the aluminum alloy formwork and correct and reinforce; utilize the temporary installation platform 21 to set up an overall steel truss 1 operation platform; install the jack 7 and the climbing pole 5, the bottom of the climbing pole 5 Weld firmly with the steel bar 20, pour the first layer of concrete, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com