Novel outer wall split bolt hole three-color polyurethane plugging process

A technology for tie bolts and tie bolt holes, applied in polyurea/polyurethane coatings, building components, coatings, etc., can solve problems such as low work efficiency, difficulty in checking hole sealing and tightness, and moisture return in interior walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

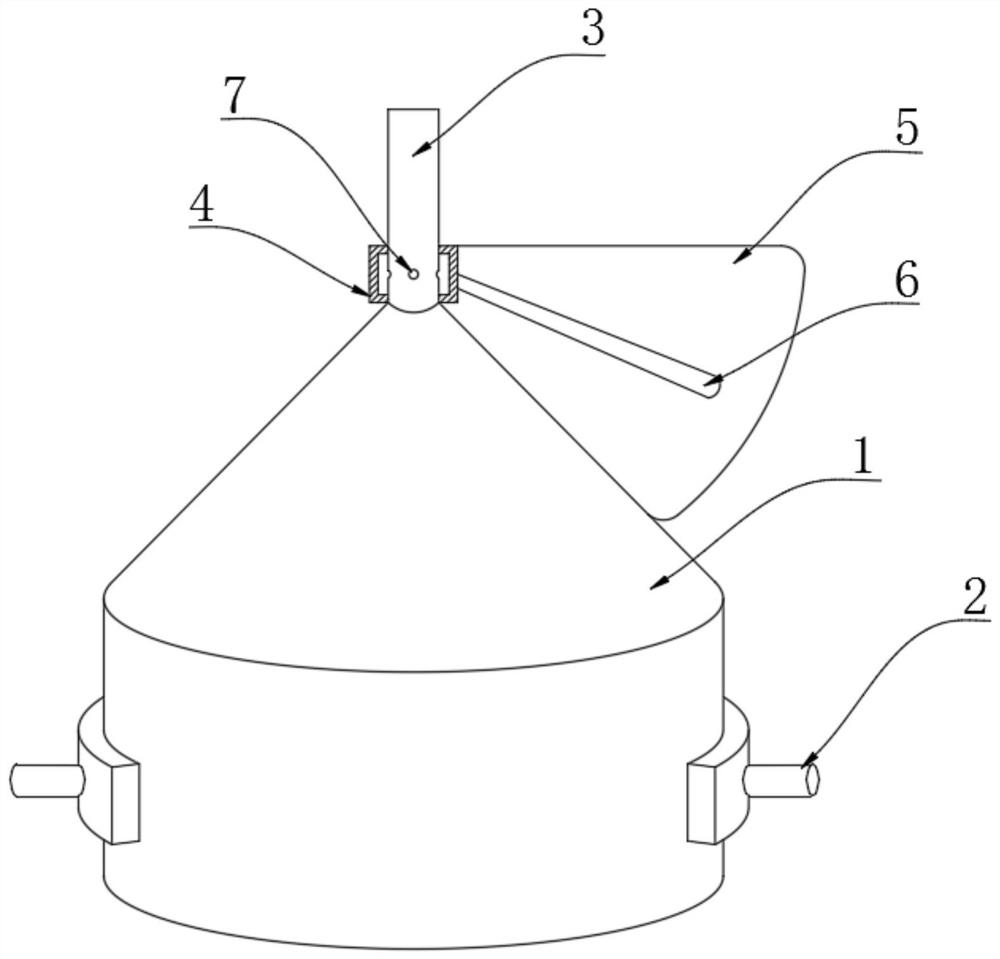

[0039] refer to figure 1 , a new type of three-color polyurethane sealing process for the pull bolt hole of the outer wall, including the following process:

[0040] S1, basic treatment

[0041]After the external wall formwork is removed, pull out the double bolt holes of the external wall, cut the PVC pipe exposed on the wall flat, and clean up the residual mortar around the holes; Break the PVC pipe in the hole, and clean the hole with a wire brush or air pump;

[0042] S2. Waterproof expansion cement mortar filling

[0043] Rinse and moisten the pull bolt holes with water one day in advance, stuff the waterproof expansion cement mortar into the bolt holes with an iron trowel. Tamp the sides at the same time, and finally use an iron trowel to wipe the bolt hole on the outside of the wall and the wall surface to a concave of 5mm, and smooth the inside;

[0044] S3, waterproof expansion cement mortar maintenance

[0045] The holes of the tie bolts are sealed with waterpro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com