Transverse bridge direction and vertical direction bidirectional earthquake-resistant stop block structure suitable for bridge

A technology of transverse bridge direction and anti-seismic retaining, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of difficult repair of bridge damage, damage of bearings, damage of bearings, etc., and achieve easy maintenance and replacement of parts, The effect of reducing the possibility of collision and preventing the damage of falling beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below the present invention is further described:

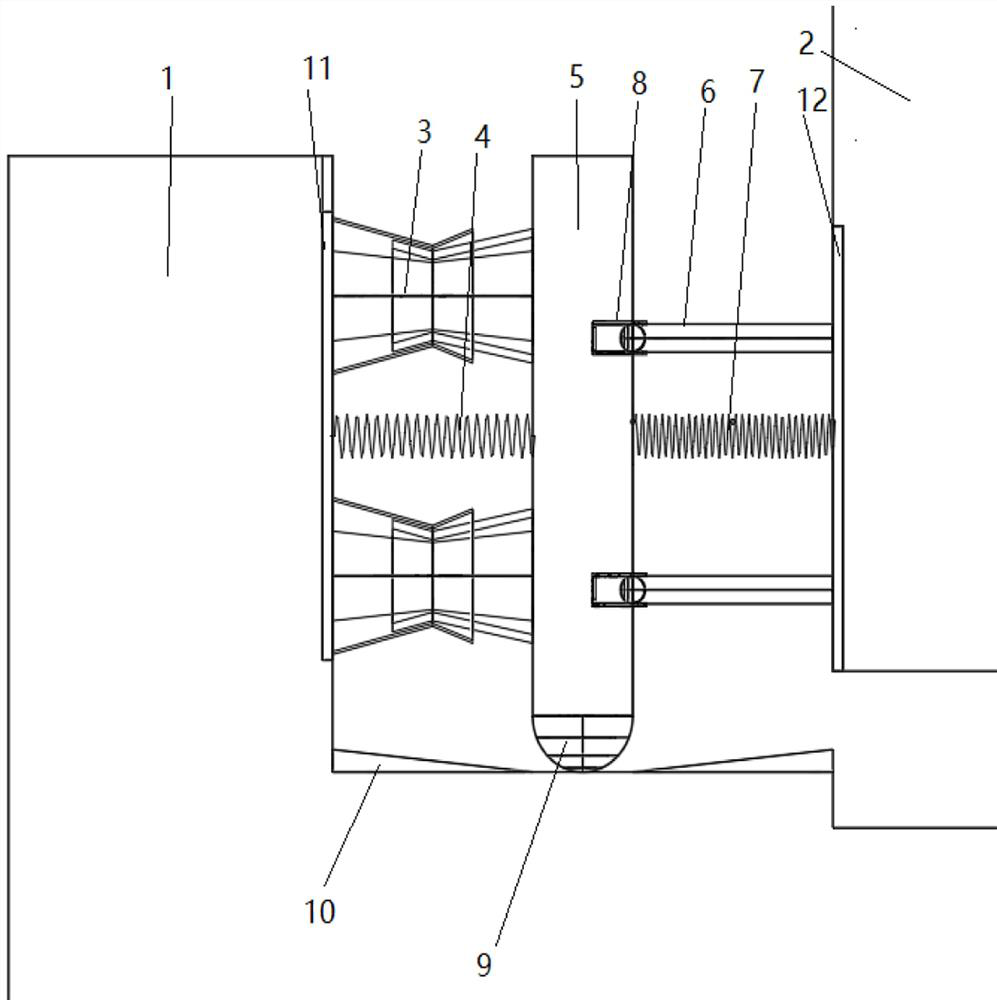

[0027] see Figure 1-5 ,

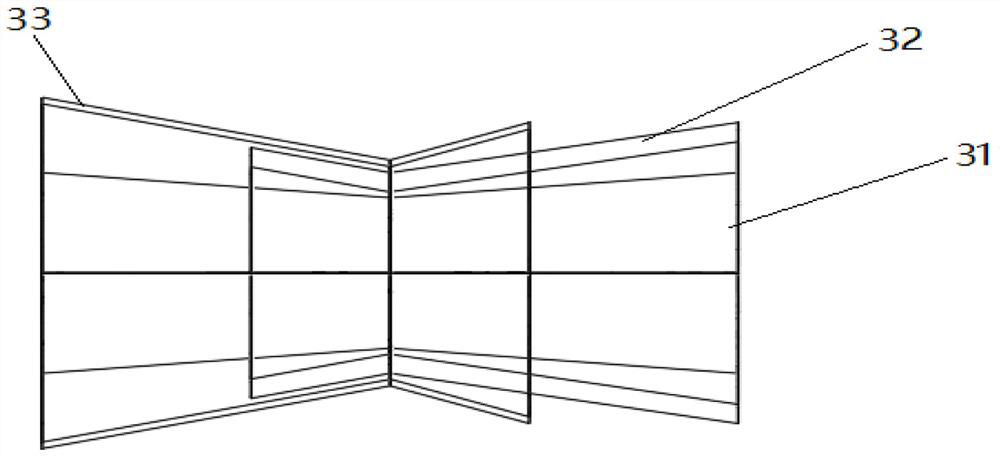

[0028] The invention discloses a two-way anti-seismic stopper structure suitable for bridges in the transverse bridge direction and vertical direction, comprising a rectangular concrete stopper 1, a bridge main body 2, an embedded circular platform composite column 3, a carbon steel spring 4, and a steel stopper in the middle 5. Suspension rib 6, alloy steel spring 7, high-performance buffer plate 8, semicircular pulley 9, triangular tilting block 10, block pre-embedded steel plate 11, main beam pre-embedded steel plate 12, square digging hole 13, inner circle Table-top elastic column 31, middle round table-type hollow column 32, outer round table-type hollow column 33, carbon steel spring 4 and embedded round table composite column 3 are arranged between the rectangular concrete block 1 and the middle steel block 5 connected. The right side of the middle rigid block 5 contains a square di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com