Reflective printed elastic fabric and preparation process thereof

A preparation process and technology of elastic cloth, which is applied in the direction of textile, fabric, textile and papermaking, etc., can solve the problems of easy wrinkle of reflective cloth, high hardness of reflective cloth, poor washing resistance, etc., and achieve superior wear resistance and good wrinkle resistance , Strong washing resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

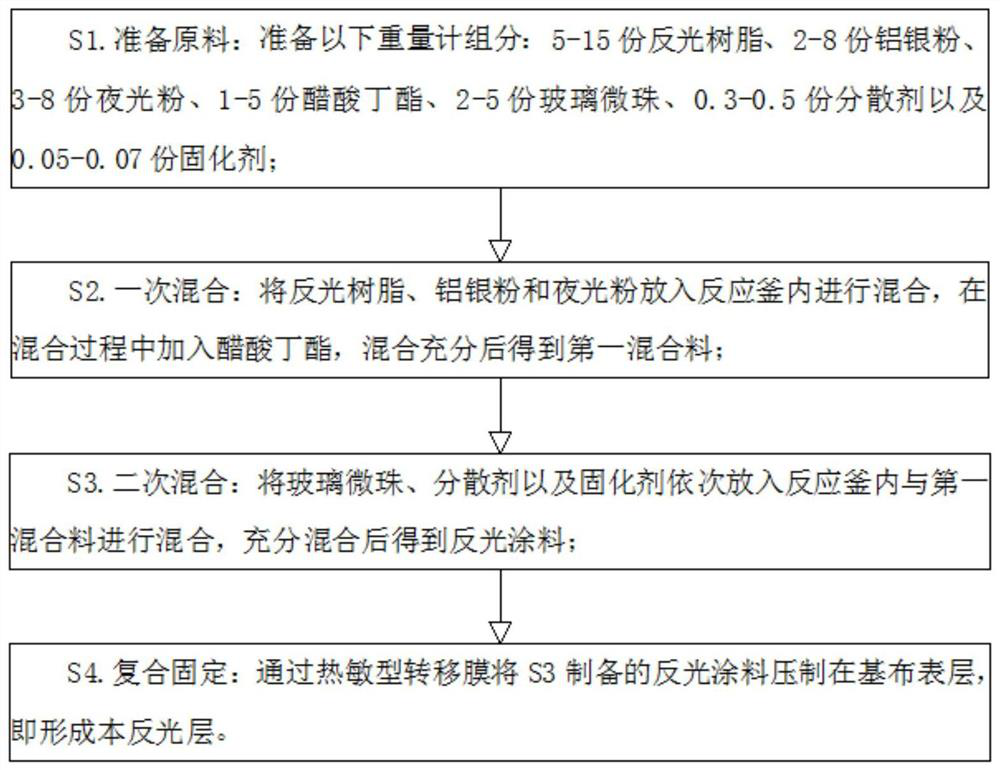

[0034] A reflective printed elastic fabric comprises a base layer and a reflective layer, the reflective layer is compositely fixed on the surface of the base layer, and the base layer includes 44% nylon fiber, 44% polyester fiber and 12% spandex fiber.

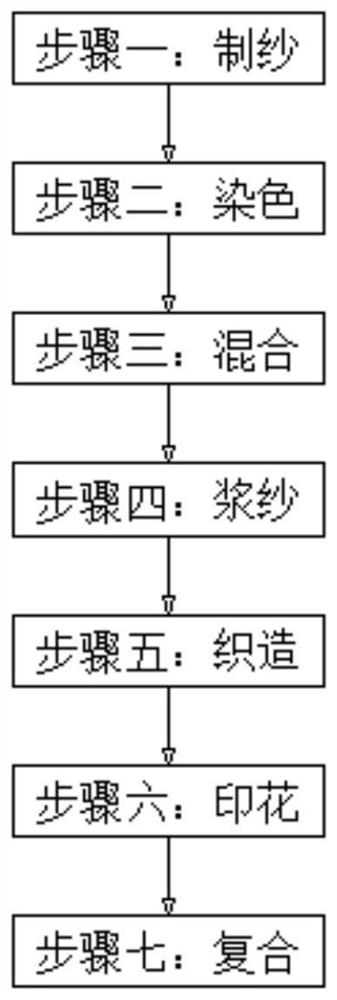

[0035] A preparation process of reflective printed elastic cloth, comprising the following steps:

[0036] Step 1: yarn making: nylon fiber, polyester fiber and spandex fiber are spun on a spinning machine in sequence to obtain nylon yarn, polyester yarn and spandex yarn;

[0037] Step 2: Dyeing: Put the nylon yarn, polyester yarn and spandex yarn into the dyeing tank respectively, and then inject the colorant into the dyeing tank for dip-dyeing, so that the colorant is completely submerged in the nylon yarn, polyester yarn and spandex yarn ;

[0038] Step 3: Mixing: The nylon yarn, polyester yarn and spandex yarn obtained in step 2 are wound on the bobbin in turn to form a bobbin, and then the nylon bobbin, polyester bobbin...

Embodiment 2

[0058] A reflective printed elastic fabric comprises a base layer and a reflective layer, the reflective layer is compositely fixed on the surface of the base layer, and the base layer includes 42% nylon fiber, 42% polyester fiber and 16% spandex fiber.

[0059] A preparation process of reflective printed elastic cloth, comprising the following steps:

[0060] Step 1: yarn making: nylon fiber, polyester fiber and spandex fiber are spun on a spinning machine in sequence to obtain nylon yarn, polyester yarn and spandex yarn;

[0061] Step 2: Dyeing: Put the nylon yarn, polyester yarn and spandex yarn into the dyeing tank respectively, and then inject the colorant into the dyeing tank for dip-dyeing, so that the colorant is completely submerged in the nylon yarn, polyester yarn and spandex yarn ;

[0062] Step 3: Mixing: The nylon yarn, polyester yarn and spandex yarn obtained in step 2 are wound on the bobbin in turn to form a bobbin, and then the nylon bobbin, polyester bobbin...

Embodiment 3

[0082] A reflective printed elastic fabric comprises a base layer and a reflective layer, the reflective layer is compositely fixed on the surface of the base layer, and the base layer includes 43% nylon fiber, 43% polyester fiber and 14% spandex fiber.

[0083] A preparation process of reflective printed elastic cloth, comprising the following steps:

[0084] Step 1: yarn making: nylon fiber, polyester fiber and spandex fiber are spun on a spinning machine in sequence to obtain nylon yarn, polyester yarn and spandex yarn;

[0085] Step 2: Dyeing: Put the nylon yarn, polyester yarn and spandex yarn into the dyeing tank respectively, and then inject the colorant into the dyeing tank for dip-dyeing, so that the colorant is completely submerged in the nylon yarn, polyester yarn and spandex yarn ;

[0086] Step 3: Mixing: The nylon yarn, polyester yarn and spandex yarn obtained in step 2 are wound on the bobbin in turn to form a bobbin, and then the nylon bobbin, polyester bobbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com