Machine tool heat treatment device for machining nuts

A technology of heat treatment device and heating device, which is applied in the field of nut processing, and can solve the problems of high cost, inability to heat at multiple levels, and burns to staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

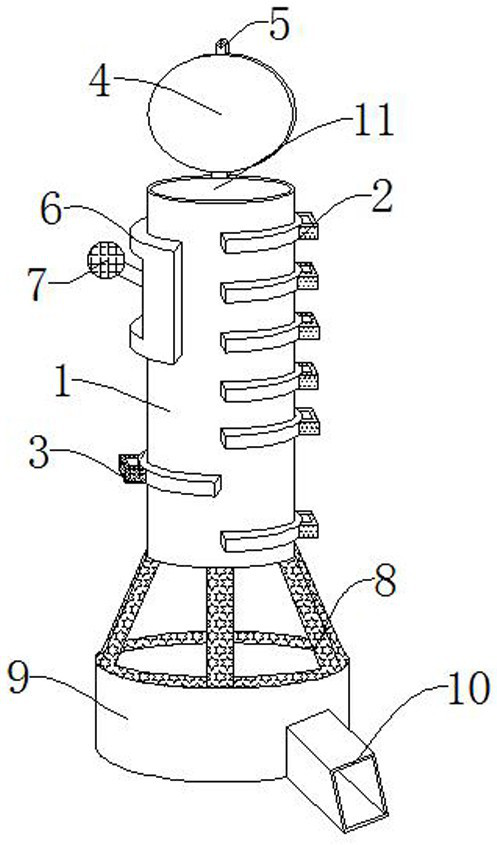

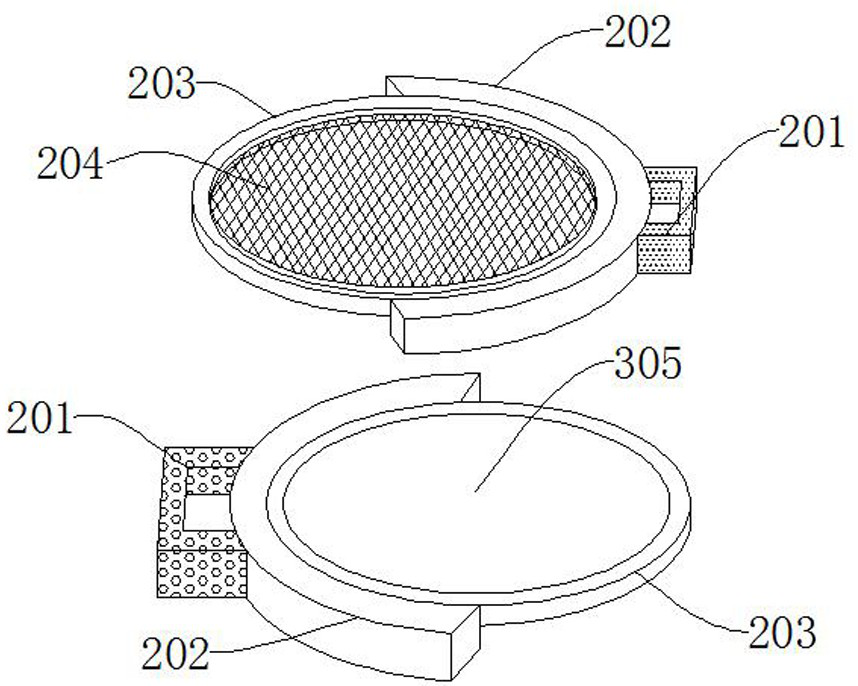

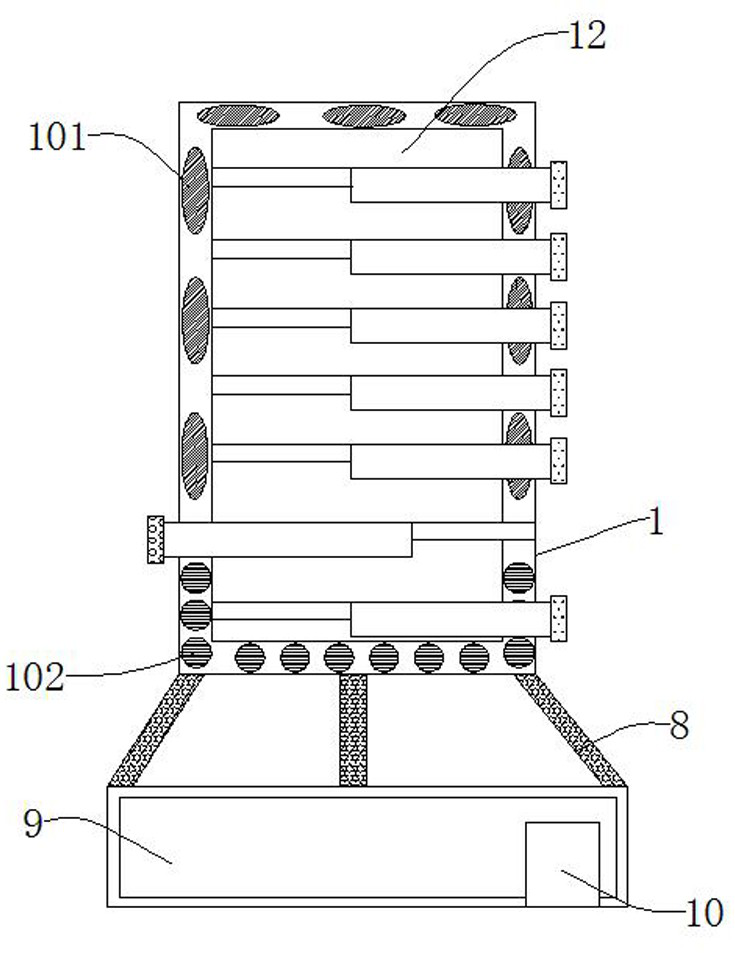

[0020] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 A schematic diagram of the overall structure of a preferred embodiment of a machine tool heat treatment device for processing nuts provided by the present invention; figure 2 for figure 1 The structural schematic diagram of the push-pull body shown; image 3 for figure 1 Schematic diagram of the overall cross-section shown. A machine tool heat treatment device for processing nuts includes a device body 1, a push-pull body 2 and an isolation layer 3, a push-pull body 2 is arranged on the right side of the device body 1, and the push-pull body 2 is movably connected with the device body 1, and the lower end of the push-pull body 2 is arranged There is an isolation layer 3, and the isolation layer 3 is fixedly connected to the push-pull body 2. A heating device 101 is arranged i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com