Method for preparing high-fluidity carbon black master batch by in-situ degradation of polypropylene with peroxide

A fluid carbon black and peroxide technology, applied in the field of carbon black masterbatch and its preparation, can solve the problems of low flow rate, difficulty in dispersion, high production cost, high energy consumption, etc. Melt flow rate stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

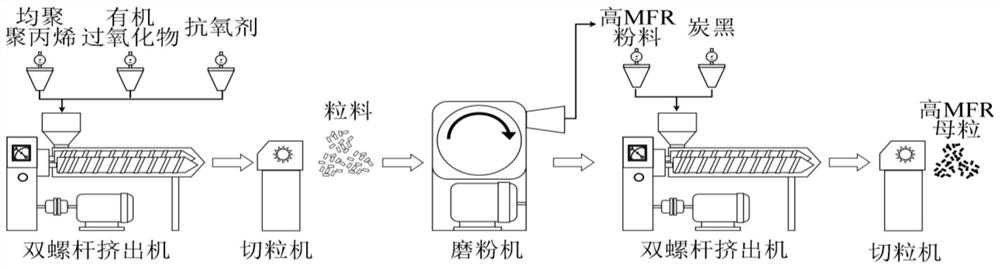

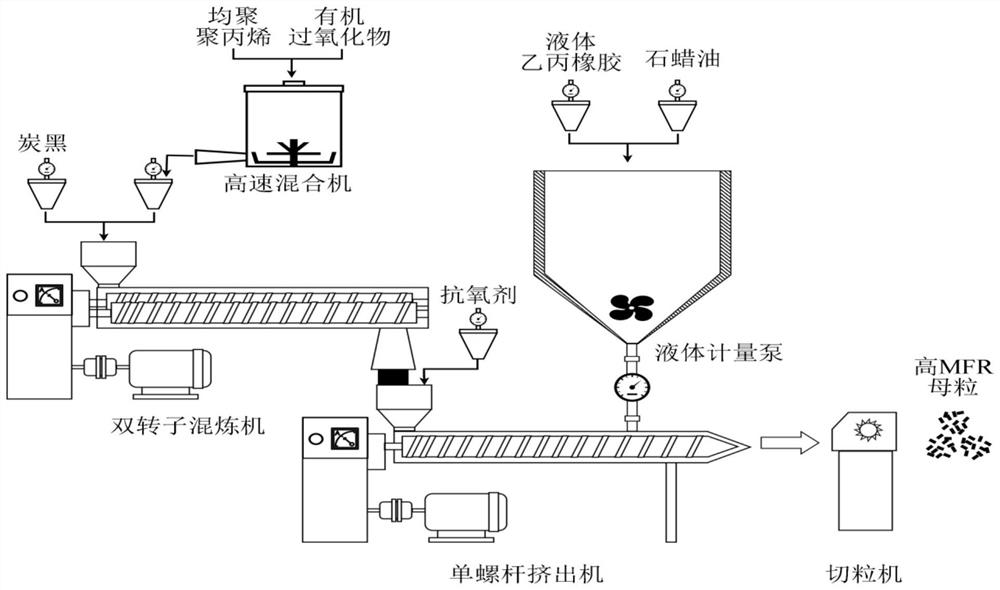

Method used

Image

Examples

Embodiment 1

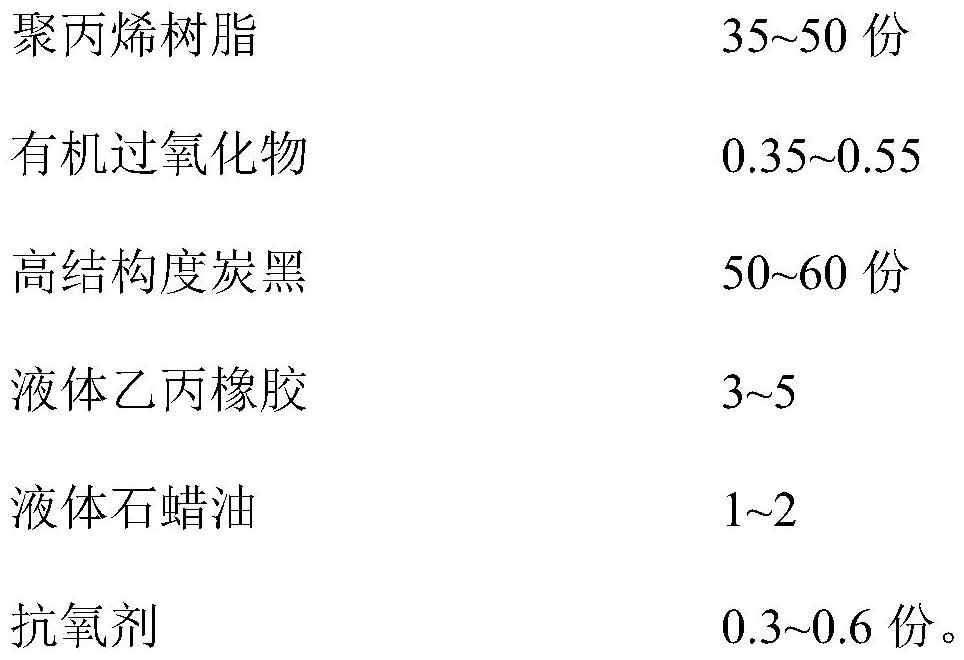

[0037] Raw material formula (mass ratio, part):

[0038] Homopolypropylene powder (load 2160g, MFR=400g / 10min at 230°C) 35,2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane 0.35, high structure carbon Black (15nm, specific surface area 100m 2 / g, oil absorption value 105mL / g, tinting strength 100) 60, binary liquid ethylene propylene rubber (number average molecular weight 35000) 3, liquid paraffin oil (100 ℃ kinematic viscosity 6 ~ 12mm 2 / s) 1~2, antioxidant B215 0.3.

[0039] Preparation Process:

[0040] High-speed mixing of powdered homopolypropylene resin and organic peroxide: in a high-speed mixer, stir the powdered homopolypropylene resin and organic peroxide in the formula raw materials at room temperature at a low speed of 500 rpm or less for 2 minutes and discharge to main silo.

[0041] Double-rotor continuous mixer blending: the integrated feeding system is turned on to transport the powdered homopolypropylene resin, organic peroxide mixture, and high-structure car...

Embodiment 2

[0046] Raw material formula (mass ratio, part):

[0047] Homopolypropylene powder (load 2160g, MFR=400g / 10min at 230°C) 50,2,5-Dimethyl-2,5-bis(t-butylperoxy)hexane 0.2,3,6, 9-triethyl-3,6,9-trimethyl-1,4,7-triperoxynonane 0.2, high structure carbon black (20nm, specific surface area 120m 2 / g, oil absorption value 125mL / g, tinting strength 105)50, ternary liquid ethylene propylene rubber (number average molecular weight is 40000)3, liquid paraffin oil (kinematic viscosity at 100°C is 10mm 2 / s) 1, antioxidant B225 0.5.

[0048] Preparation Process:

[0049] High-speed mixing of powdered homopolypropylene resin and organic peroxide: in a high-speed mixer, stir the powdered homopolypropylene resin and organic peroxide in the formula raw materials at room temperature at a low speed of 500 rpm or less for 2 minutes and discharge to main silo.

[0050] Double-rotor continuous mixer blending: the integrated feeding system is turned on to transport the powdered homopolypropylene...

Embodiment 3

[0055] Raw material formula (mass ratio, part):

[0056] Homopolypropylene powder (load 2160g, MFR=200g / 10min at 230°C) 40,2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane 0.2,3,6, 9-triethyl-3,6,9-trimethyl-1,4,7-triperoxynonane 0.2, di-tert-butyl peroxide 0.15, high structure carbon black (15nm, specific surface area 120m 2 / g, oil absorption value 110mL / g, tinting strength 105) 50, binary liquid ethylene propylene rubber (number average molecular weight 50000) 5, liquid paraffin oil (kinematic viscosity at 100°C is 12mm) 2 / s) 2, antioxidant B215 0.3, B225 0.3.

[0057] Preparation Process:

[0058] High-speed mixing of powdered homopolypropylene resin and organic peroxide: in a high-speed mixer, stir the powdered homopolypropylene resin and organic peroxide in the formula raw materials at room temperature at a low speed of 500 rpm or less for 2 minutes and discharge to main silo.

[0059] Double-rotor continuous mixer blending: the integrated feeding system is turned on to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com