Polystyrene latex microspheres and preparation method thereof

A technology of polystyrene latex and styrene monomer, which is applied in the direction of instruments, analytical materials, measuring devices, etc., can solve the problems of coupling failure coupling efficiency, poor improvement effect, and reduce the stability of latex microspheres, etc., to achieve Improve the coupling success rate and coupling efficiency, high particle size uniformity, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides the preparation method of above-mentioned polystyrene latex microsphere, comprises the steps:

[0055] Mix the preparation raw materials and water, heat and stir to carry out emulsion polymerization.

[0056]In one example, mixing the preparation materials refers to adding the surfactant to the water, heating and stirring, and then adding the rest of the preparation materials.

[0057] In one example, heating and stirring refers to stirring at a rate of 80 rpm to 500 rpm under the temperature condition of 65° C. to 95° C.

[0058] Specifically, the temperature of heating and stirring includes but not limited to the following temperatures: 65°C, 70°C, 75°C, 78°C, 80°C, 82°C, 85°C, 90°C, 95°C.

[0059] The stirring rate includes but not limited to the following rates: 80rpm, 100rpm, 150rpm, 200rpm, 250rpm, 300rpm, 350rpm, 380rpm, 400rpm, 420rpm, 450rpm, 500rpm.

[0060] The present invention also provides the application of the above-...

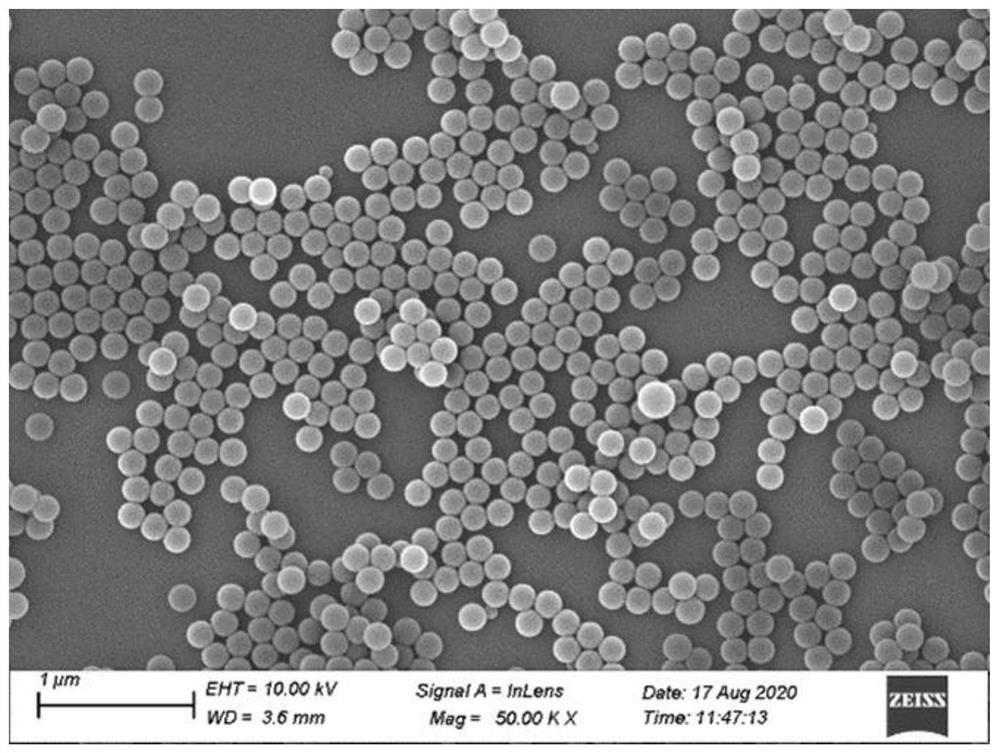

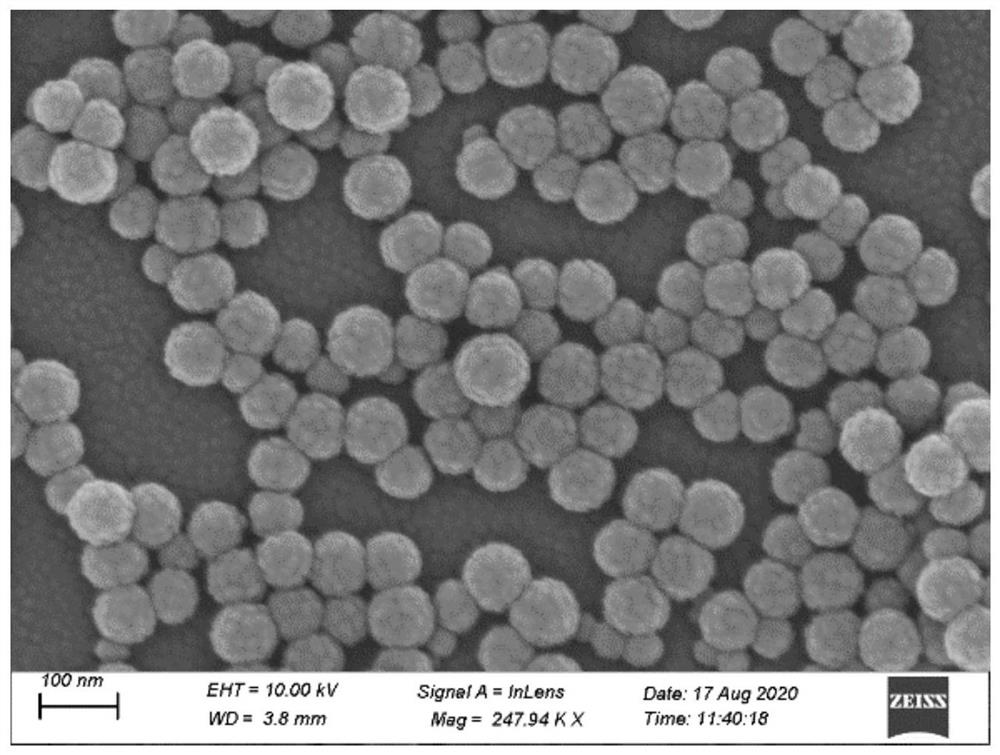

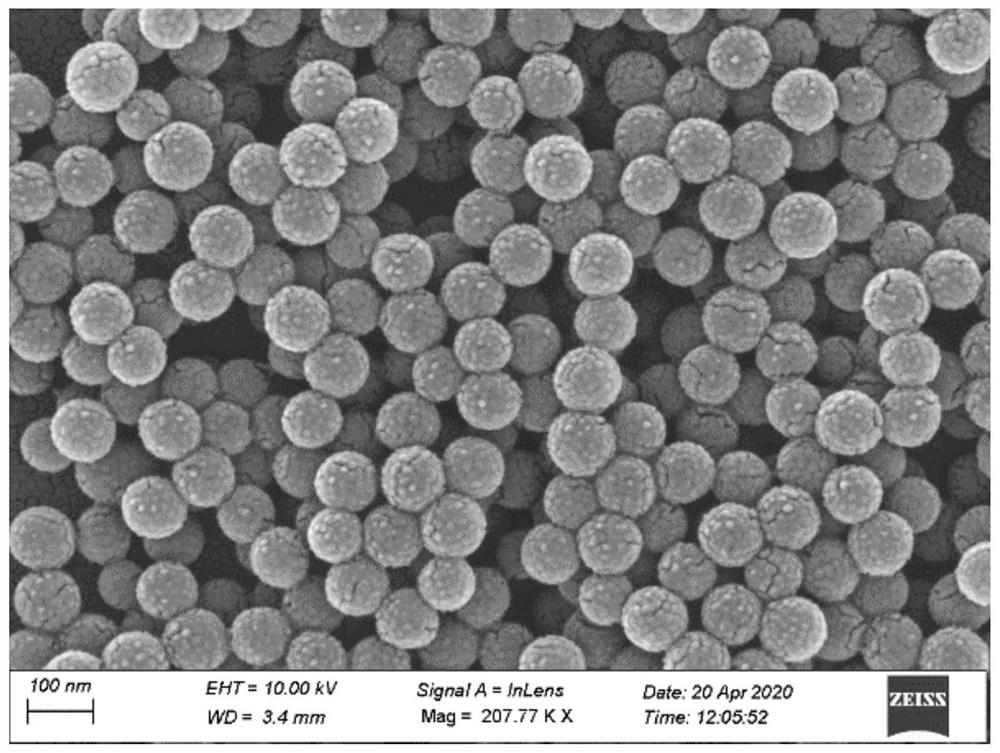

Embodiment 1

[0071] The present embodiment provides a kind of polystyrene latex microsphere, and its preparation raw material and method are as follows:

[0072] (1) Put 7 grams of styrene, 50 mL of water, 0.2 grams of methacrylic acid, 0.03 grams of sodium dodecylbenzenesulfonate, and 0.17 grams of Triton X-100 into a 100 mL four-necked flask with a stirrer, and Under the conditions of 80 ° C and a stirring rate of 400 rpm, the polymerization reaction was carried out for 1 hour;

[0073] (2) 0.1 g of potassium persulfate was added to the reaction system, and further polymerized at 80° C. and a stirring rate of 400 rpm for 8 hours to obtain polystyrene latex microspheres with an average particle size of 89.57 nm.

Embodiment 2

[0075] The present embodiment provides a kind of polystyrene latex microsphere, and its preparation raw material and method are the same as embodiment 1, and the main difference is: change 0.17 gram of Triton X-100 to Tween-20 0.3 gram (in order to guarantee microsphere The diameters are basically the same, and non-equal mass replacements are used).

[0076] details as follows:

[0077] (1) Put 7 grams of styrene, 50 mL of water, 0.2 grams of methacrylic acid, 0.03 grams of sodium dodecylbenzene sulfonate, and 200.3 grams of Tween into a 100 mL four-necked flask with a stirrer. Polymerization was carried out for 1 hour at 80°C and a stirring rate of 400rp;

[0078] (2) 0.1 g of potassium persulfate was added to the reaction system, and further polymerization was carried out at 80° C. and a stirring rate of 400 rpm for 8 hours to obtain polystyrene latex microspheres with an average particle size of 87.46 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com