Automatic strengthening system and process for preparing hydrogen peroxide based on anthraquinone method

A technology of hydrogen peroxide and anthraquinone method, applied in peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, chemical instruments and methods, etc., can solve the problem of low system reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

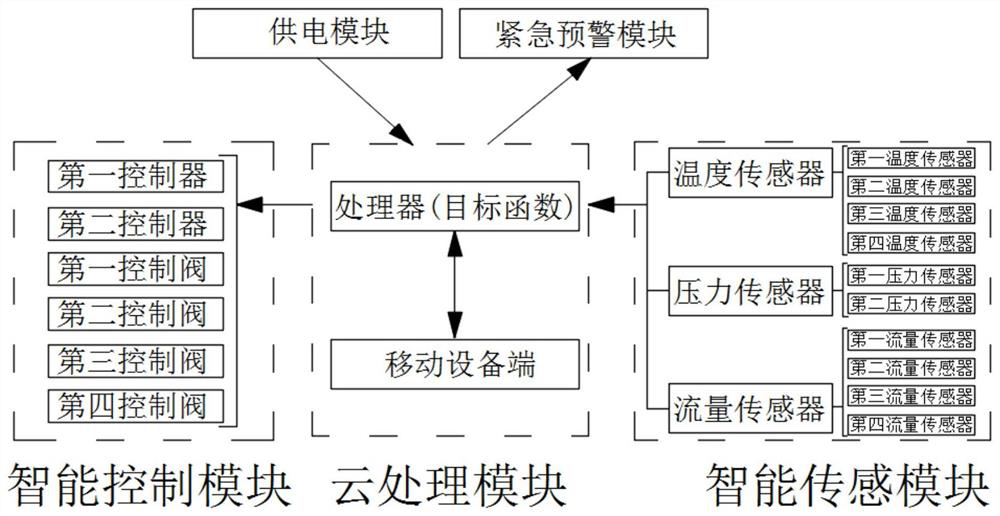

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

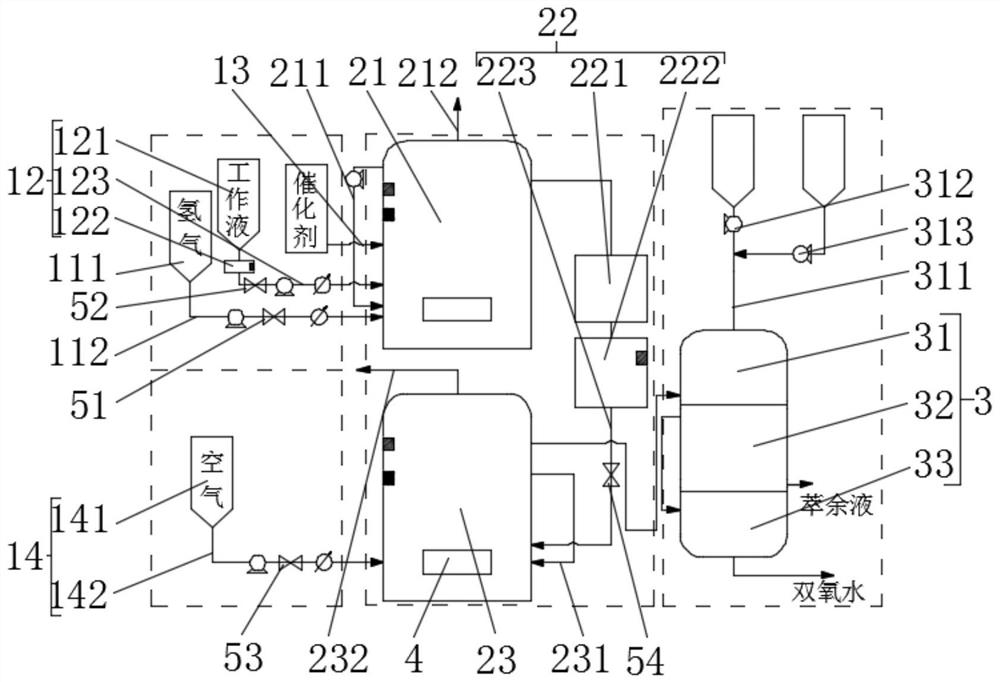

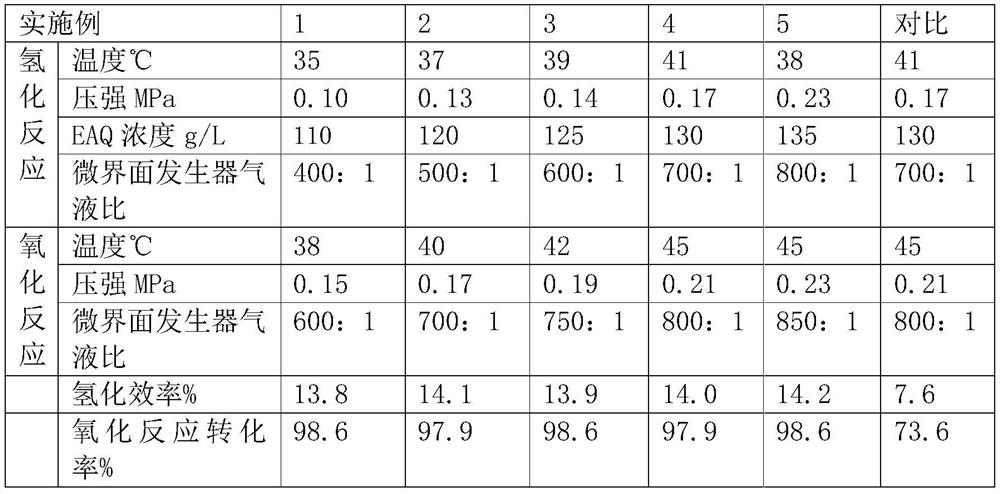

[0107] Use above-mentioned system and process to carry out anthraquinone method to prepare hydrogen peroxide, wherein:

[0108] Hydrogenation reaction: In the process, a palladium catalyst is added to the hydrogenation tower, and an anthraquinone derivative-containing working solution composed of 2-ethylanthraquinone (EAQ), heavy aromatics (AR) and trioctyl phosphate is introduced, wherein EAQ The concentration is 110g / L, the reaction temperature is 35°C, the reaction pressure is 0.10MPa, and the gas-liquid ratio in the micro-interface generator is 400:1.

[0109] Oxidation reaction: The reaction temperature in the hydrogenation tower in the process is 38°C, the reaction pressure is 0.15MPa, and the gas-liquid ratio in the micro-interface generator is 600:1.

Embodiment 2

[0111] Use above-mentioned system and process to carry out anthraquinone method to prepare hydrogen peroxide, wherein:

[0112] Hydrogenation reaction: In the process, a palladium catalyst is added to the hydrogenation tower, and an anthraquinone derivative-containing working solution composed of 2-ethylanthraquinone (EAQ), heavy aromatics (AR) and trioctyl phosphate is introduced, wherein EAQ The concentration is 120g / L, the reaction temperature is 37°C, the reaction pressure is 0.13MPa, and the gas-liquid ratio in the micro-interface generator is 500:1.

[0113] Oxidation reaction: In the process, the reaction temperature in the hydrogenation tower is 40°C, the reaction pressure is 0.17MPa, and the gas-liquid ratio in the micro-interface generator is 700:1.

Embodiment 3

[0115] Use above-mentioned system and process to carry out anthraquinone method to prepare hydrogen peroxide, wherein:

[0116] Hydrogenation reaction: In the process, a palladium catalyst is added to the hydrogenation tower, and an anthraquinone derivative-containing working solution composed of 2-ethylanthraquinone (EAQ), heavy aromatics (AR) and trioctyl phosphate is introduced, wherein EAQ The concentration is 125g / L, the reaction temperature is 39°C, the reaction pressure is 0.14MPa, and the gas-liquid ratio in the micro-interface generator is 600:1.

[0117] Oxidation reaction: In the process, the reaction temperature in the hydrogenation tower is 42°C, the reaction pressure is 0.19MPa, and the gas-liquid ratio in the micro-interface generator is 750:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com