Polyvinylidene fluoride filter membrane as well as preparation method and application thereof

A polyvinylidene fluoride and filter membrane technology, applied in the field of membrane materials, can solve the problems of limiting the development and application of polyvinylidene fluoride filter membranes, high time cost, poor tensile strength, etc., and achieve high cost performance, large nano The effect of increasing the amount of dirt and improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

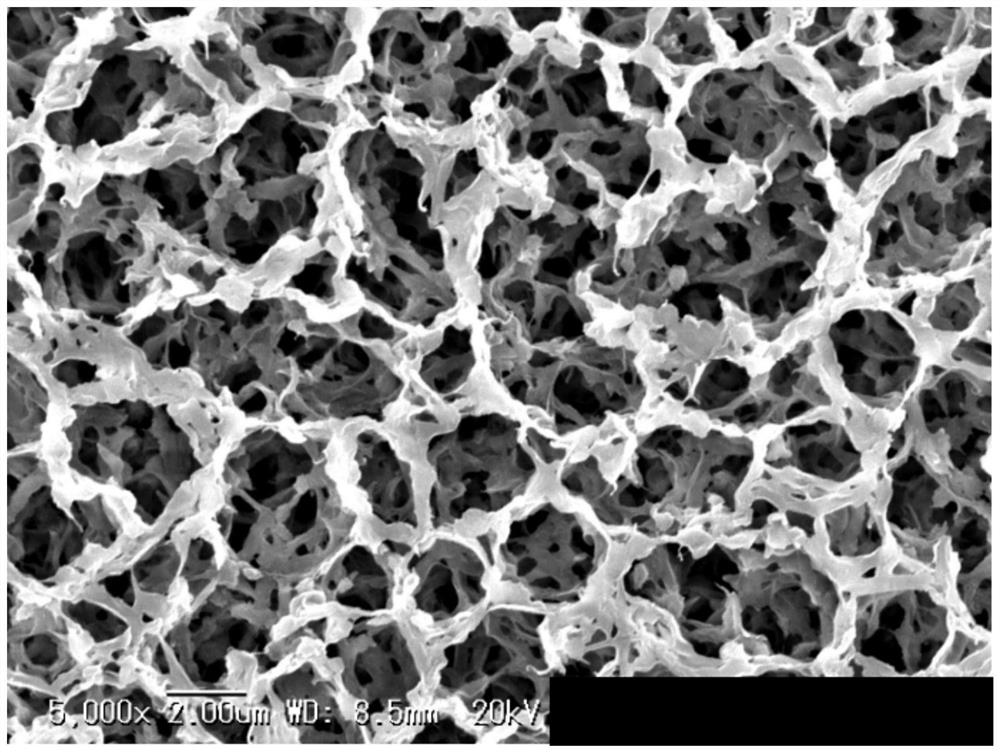

Image

Examples

Embodiment 1

[0062] A preparation method of a polyvinylidene fluoride filter membrane, comprising the following steps:

[0063] Step 1: configuring the casting solution, and casting it on the carrier to form a nascent film; the casting solution includes the following components by weight: 13 parts of PVDF resin, 3 parts of small molecule additives and 84 parts of the first organic solvent; Among them, the number average molecular weight of PVDF resin is 1 million, the small molecule additive is LiCl; the first organic solvent is N-methylpyrrolidone;

[0064] Step 2: Place the primary film in an air environment with a temperature of 20°C and an absolute humidity of 25g H 2 The air flow of 0 / kg is blown to the surface of the primary film for pre-separation treatment, the relative velocity between the air flow and the liquid film is 65m / min, and the duration is 18s. At this moment, the cloud point just reached, and the pre-separation is completed;

[0065] Step 3: Place the primary film afte...

Embodiment 2

[0067] A preparation method of a polyvinylidene fluoride filter membrane, comprising the following steps:

[0068] Step 1: configure the casting solution, and cast it on the carrier to form a nascent film; the casting solution includes the following components by weight: 18 parts of PVDF resin, 4 parts of small molecule additives, 76 parts of the first organic solvent and 2 parts of deionized water; wherein the number average molecular weight of the PVDF resin is 500,000, the small molecule additive is tetrahydrofuran; the first organic solvent is triethyl phosphate;

[0069] Step 2: Place the primary film in an air environment with a temperature of 30°C and an absolute humidity of 21g H 2 The air flow of 0 / kg is blown onto the surface of the primary film for pre-separation treatment, the relative velocity between the air flow and the liquid film is 6m / s, and the duration is 13s. At this moment, the cloud point is just reached, and the pre-separation is completed;

[0070] St...

Embodiment 3

[0072] A preparation method of a polyvinylidene fluoride filter membrane, comprising the following steps:

[0073] Step 1: configure the casting solution, and cast it on the carrier to form a nascent film; the casting solution includes the following components by weight: 15 parts of PVDF resin, 3 parts of small molecule additives and 82 parts of the first organic solvent; Among them, the number average molecular weight of PVDF resin is 800,000, and the small molecule additive is acetone; the first organic solvent is dimethylacetamide;

[0074] Step 2: Place the primary film in an air environment with a temperature of 15°C and an absolute humidity of 29g H 2 The air flow of 0 / kg is blown onto the surface of the primary film for pre-separation treatment, the relative velocity between the air flow and the liquid film is 55m / min, and the duration is 16s. At this moment, the cloud point is just reached, and the pre-separation is completed;

[0075] Step 3: Place the primary film a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com