System and method for removing pollutants in flue gas collected from sodium sulfide hot-melting tank

A sodium sulfide and pollutant technology, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of sodium sulfide environmental pollution and potential safety hazards, and achieve the effect of ensuring clean emissions and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

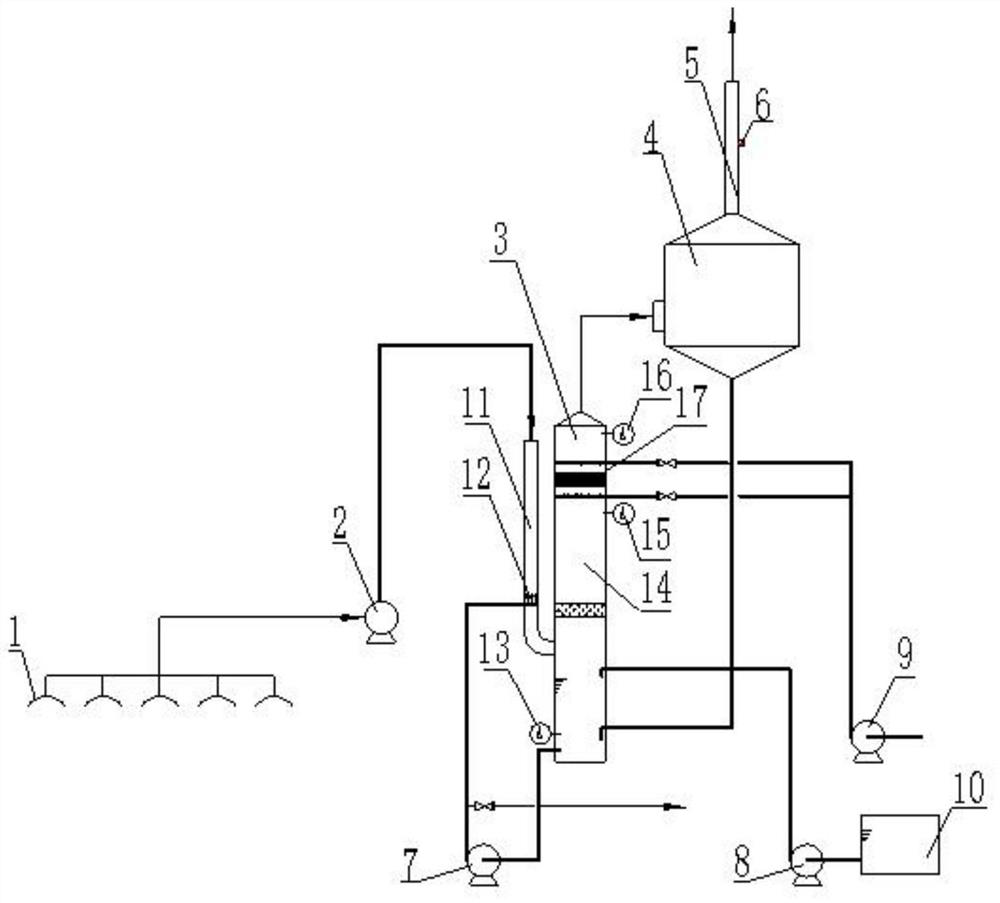

[0064] Embodiment 1: the removal method of the pollutant in the ring collection flue gas

[0065] Step 1: Set the gas collecting hood 1 on the sodium sulfide hot melting tank, utilize the suction of the induced draft fan 2 to make the vacuum (or negative pressure) in the area of the gas collecting hood edge reach 100Pa, and realize the ring on the hot melting tank All the collected flue gas is sucked and transported into the flue gas scrubber 3;

[0066] Step 2: The ring-collecting flue gas containing pollutants enters the reverse nozzle 11 of the washing tower from top to bottom, and the sodium hydroxide circulating liquid is pressurized by the lye circulating pump 7 and sprayed out by the atomizing nozzle 12. Under pressure, the cone-shaped water mist curtain is formed through the centrifugal rotation inside the nozzle. The atomized circulating fluid rises to the highest point of the reverse nozzle 11, and then falls. The sodium circulating fluid absorbs hydrogen sulfide ...

Embodiment 2

[0071] The flue gas conditions entering the scrubber are as follows: flue gas flow rate 45000Nm 3 / h, the dust concentration in the flue gas is 65mg / Nm 3 , the hydrogen sulfide concentration in the flue gas is 15mg / Nm 3 , the moisture in the flue gas is 48g / Nm 3 , the flue gas temperature is 65°C, and the circulating liquid spray volume of the scrubber is 230m 3 / h, the pH of the circulating liquid is controlled at 7.2±0.5, and the density of the circulating liquid in the scrubber is about 1.03t / m 3 .

[0072] Remove through the steps in the above-mentioned embodiment 1.

[0073] After treatment, the detection data of the exhausted flue gas is: the flow rate is 45200Nm 3 / h, the dust concentration in the flue gas is 5mg / Nm 3 , the concentration of hydrogen sulfide in the flue gas is 3mg / Nm 3 , the moisture in the flue gas is 50g / Nm 3 , the flue gas temperature is 45°C.

Embodiment 3

[0075] The flue gas conditions entering the scrubber are as follows: flue gas flow rate 35000Nm 3 / h, the dust concentration in the flue gas is 80mg / Nm 3 , the hydrogen sulfide concentration in the flue gas is 21mg / Nm 3 , the moisture in the flue gas is 52g / Nm 3 , the flue gas temperature is 72°C, and the circulating liquid spray volume of the scrubber is 210m 3 / h, the pH of the circulating liquid is controlled at 7.5±0.5, and the density of the circulating liquid in the scrubber is about 1.05t / m 3 .

[0076] Remove through the steps in the above-mentioned embodiment 1.

[0077] After treatment, the detection data of the exhausted flue gas is: the flow rate is 35600Nm 3 / h, the dust concentration in the flue gas is 3mg / Nm 3 , the hydrogen sulfide concentration in the flue gas is 2mg / Nm 3 , the moisture in the flue gas is 46g / Nm 3 , the flue gas temperature is 43°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com