An automatic loading and patching device for hydrogel slides

A hydrogel carrier, automatic feeding technology, applied in thin material handling, transportation and packaging, microneedle and other directions, can solve the problem of low patch efficiency and patch quality, patch product hygiene is not up to standard, affecting the material Hygiene and other issues, to achieve the effect of efficient and orderly loading of the carrier, improvement of the efficiency and quality of the patch, and accurate lamination of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

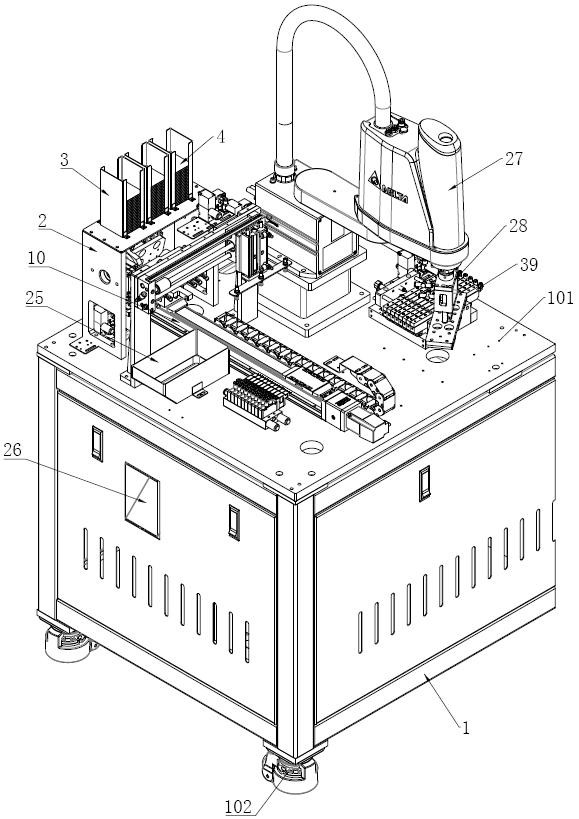

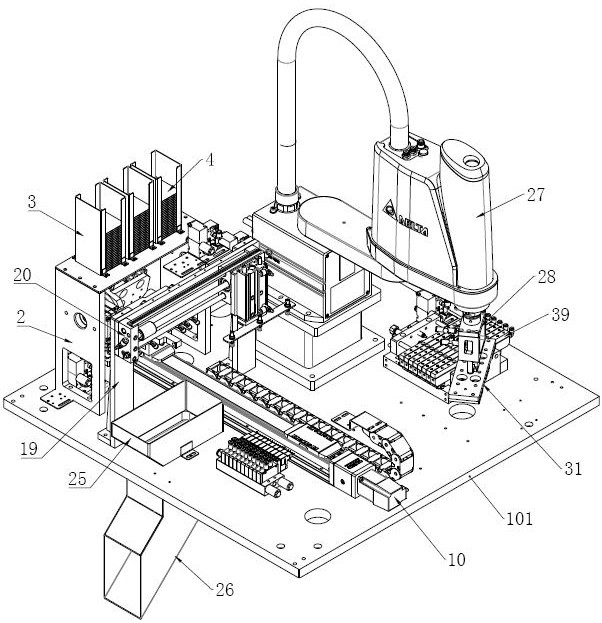

[0042] Such as Figure 1 to Figure 4 As shown, the present embodiment provides a hydrogel slide 4 automatic loading and patching device, including a frame 1, and a slide placement rack 11 driven by an electric cylinder 10 is provided on the workbench 101 of the frame 1. The slide placement rack 11 is provided with a slide positioning mechanism, and the workbench 101 is sequentially provided with slide bins for placing the hydrogel slides 4 along the sliding direction of the slide placement rack 11 and for realizing tearing off the release film. film tearing mechanism, and the slide feeding mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com