A kind of electrolyte solution and lithium secondary battery

An electrolyte and lithium salt technology, applied in the field of electrolytes and lithium secondary batteries, can solve the problems of inability to suppress high-temperature storage gas production and the negative impact of high-temperature cycle performance of batteries, so as to improve high-temperature cycle performance and inhibit high-temperature storage gas production. , the effect of excellent high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 The preparation method of high-voltage lithium-ion soft pack battery is as follows:

[0033] According to the capacity design of the battery, the capacity of the positive and negative electrode materials determines the coating area density. The positive electrode active material is a high-voltage lithium cobalt oxide material purchased from Xiamen Tungsten; the negative electrode active material is artificial graphite purchased from Shenzhen Beiterui; the separator is a PE material with a thickness of 20 μm purchased from Xingyuan. Coated ceramic diaphragm;

[0034] The positive electrode preparation step is: mix lithium cobaltate, conductive carbon black and binder polyvinylidene fluoride in a mass ratio of 96.8:2.0:1.2, and disperse them in N-methyl-2-pyrrolidone to obtain positive electrode slurry, Apply the positive electrode slurry evenly on both sides of the aluminum foil,

[0035] After drying, calendering and vacuum drying, the positive electrode ...

Embodiment 2~6

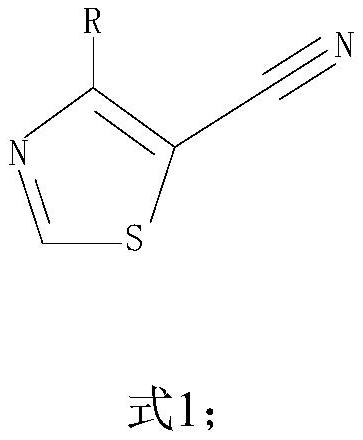

[0041] It is substantially the same as Example 1, except that the weight percent of the additive shown in Formula 1 is adjusted to 0.5%, 1%, 2%, 3% and 5%.

Embodiment 7

[0043] Substantially the same as Example 4, the difference is that the organic solvent in the electrolyte is adjusted to ethylene carbonate (EC), propylene carbonate (PC), diethyl carbonate (DEC) and propyl propionate (PP) by mass The ratio is 25:5:50:20 for mixing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com