Premixing type low-NOx burner

A pre-mixed and pre-mixed technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problem of inability to achieve low nitrogen emissions in the combustion system, and achieve the effect of reducing emissions and NOx emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

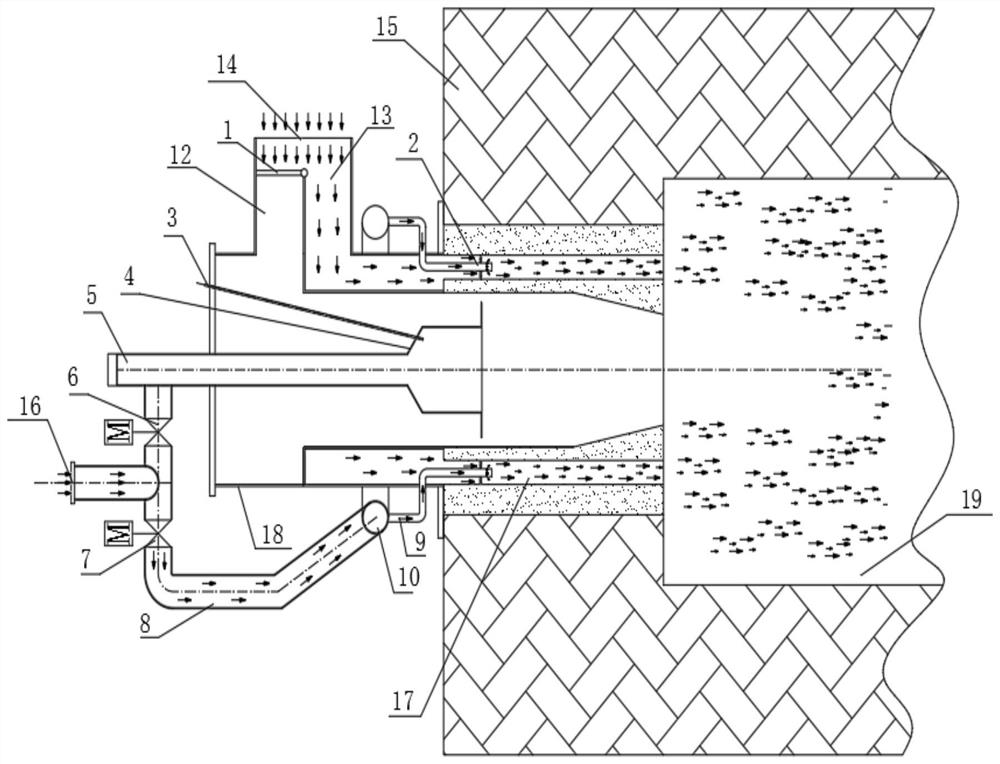

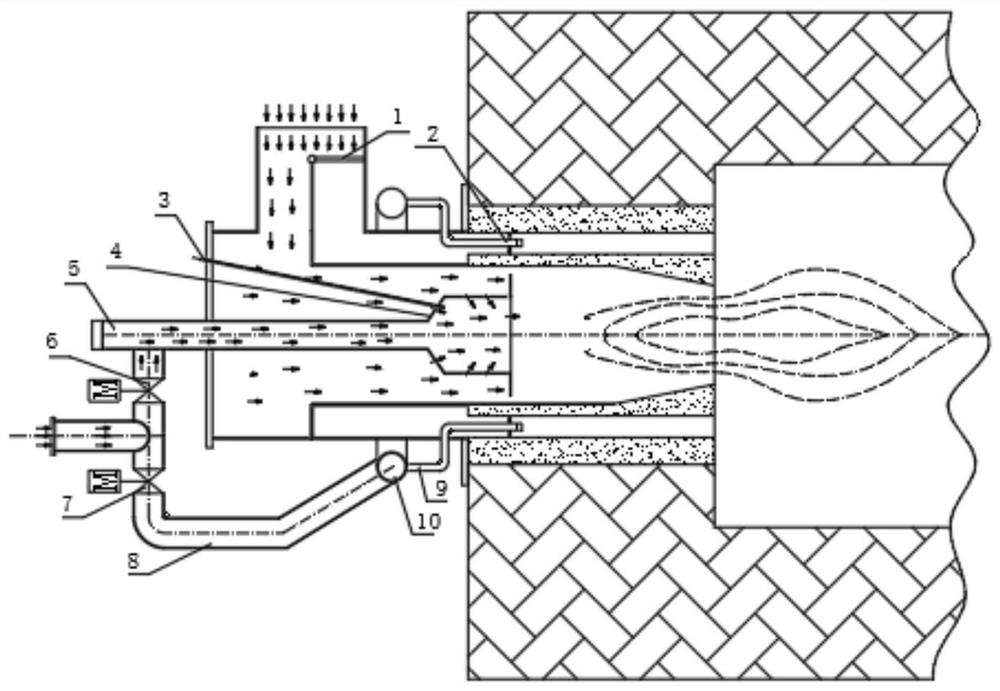

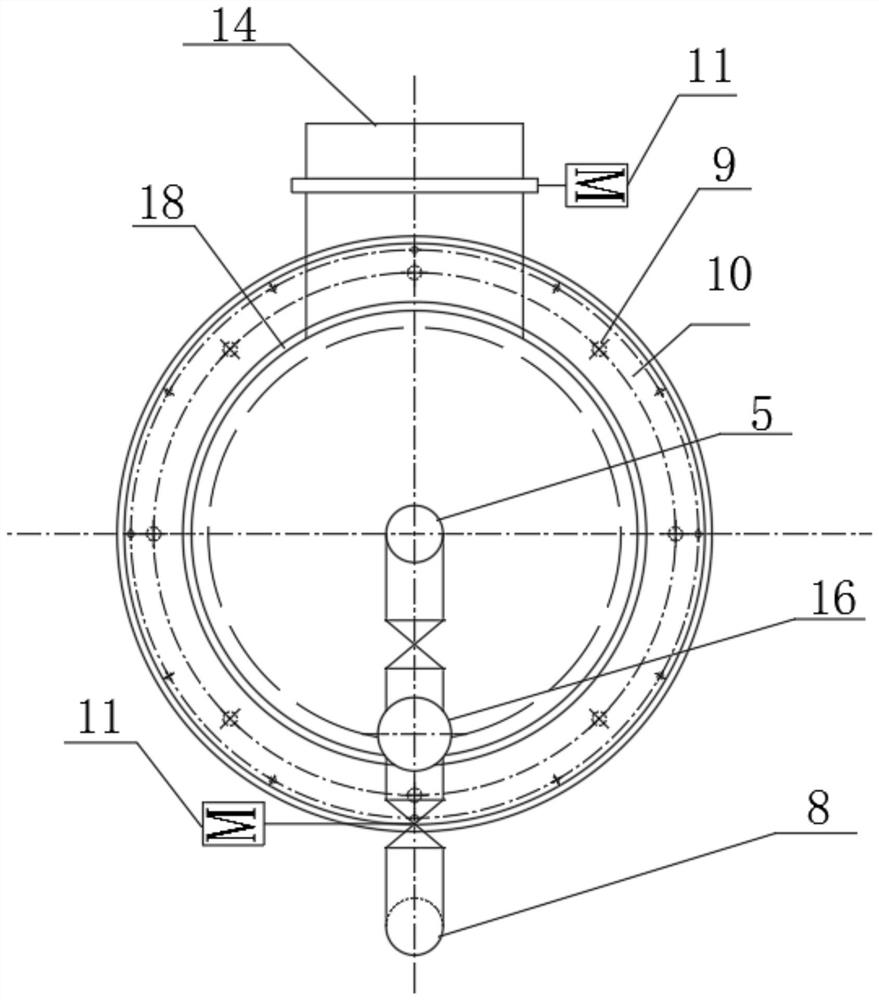

[0022] Such as figure 1 and 3 As shown, a premixed low NOx burner includes a burner body 18, the combustion part of the burner body 18 is clamped in the matching installation cavity in the burner brick 15, and the inner cavity of the burner body 18 There is a gas channel 5 for external gas to enter, and the end of the gas channel 5 is provided with a burner nozzle 4, and the burner nozzle 4 is provided with an ignition rod 3 extending to the outside of the burner body 18, which is used to ignite the burner nozzle 4. Gas / air mixture, the top of the burner body 18 is provided with an air inlet 14 communicating with the inner cavity of the burner body 18, the inner cavity of the burner body 18 is divided into a first cavity 12 and a second cavity 13, the burner The nozzle 4 and part of the gas channel 5 are set in the first cavity 12, and the air inlet 14 is installed with an air reversing butterfly valve 1 for controlling the isolation or conduction of the first cavity 12 and t...

Embodiment 2

[0025] Such as figure 1 As shown, the end of the gas passage 5 away from the burner brick 15 extends to the outside of the burner body 18, and the gas passage 5 outside the burner body 18 is connected to the gas ring pipe 10 through the gas main pipe 8, and the gas main pipe 8 is provided with a gas inlet 16, a first gas shut-off valve 6 is provided on the gas pipeline between the gas inlet 16 and the gas passage 5, and a second gas shut-off valve 6 is provided on the gas pipeline between the gas inlet 16 and the gas ring pipe 10. valve 7.

Embodiment 3

[0027] The connection position between the second cavity 13 and the premixing channel 17 is sealed. Prevent air and gas in the premixing channel 17 from leaking to the outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com