Cutterhead based on spatio-temporal arrangement of oblique angle high-pressure water jet

A high-pressure water jet and high-pressure water technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., to achieve the effect of reducing operating temperature, reducing application ratio, and increasing application ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

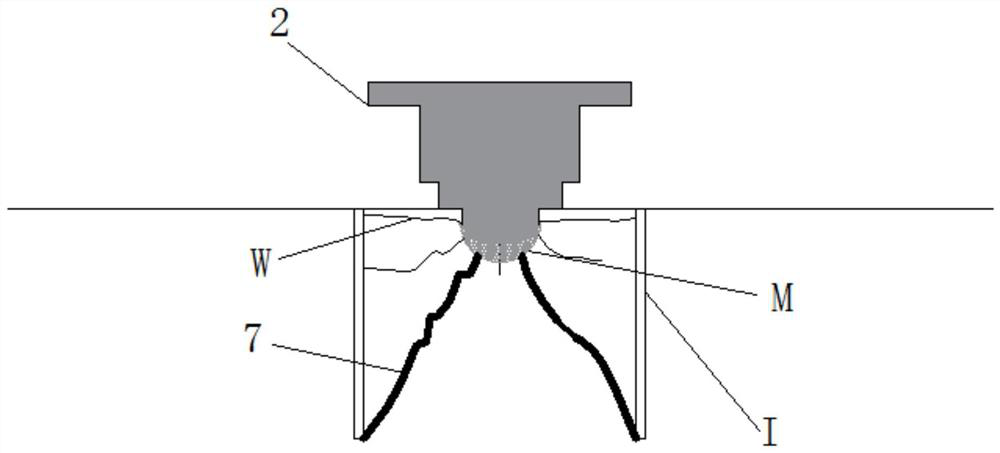

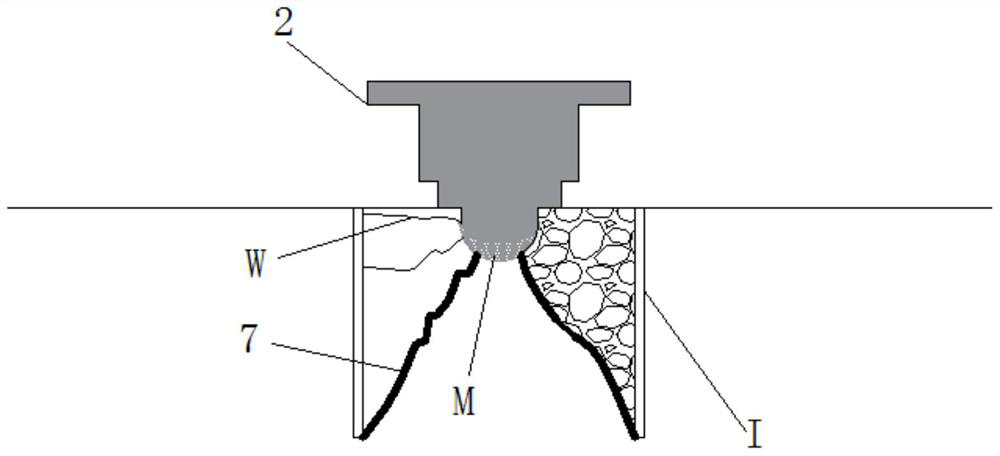

[0040] Referring to the accompanying drawings, it can be seen that: a cutter head based on the space-time arrangement of high-pressure water jets at an oblique angle, including a high-pressure water nozzle 1 at the first position, a mechanical hob 2, a high-pressure water nozzle 3 at the second position, and a mechanical scraper 4;

[0041] The No. 1 high-pressure water nozzle 1 and the No. 2 high-pressure water nozzle 3 are all obliquely arranged, and the No. 1 high-pressure water nozzle 1 and the No. 2 high-pressure water nozzle 3 are oppositely arranged 9 (such as Figure 8 , Figure 9 As shown), the inclined cutting groove is adopted t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com