Ultra-thin coal seam mining method

A technology of ultra-thin coal seam and mining method, applied in ground mining, mining equipment, mining equipment, etc., to achieve the effect of reducing possibility, small thickness limit, and huge hidden benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following is further described in detail through specific implementation methods:

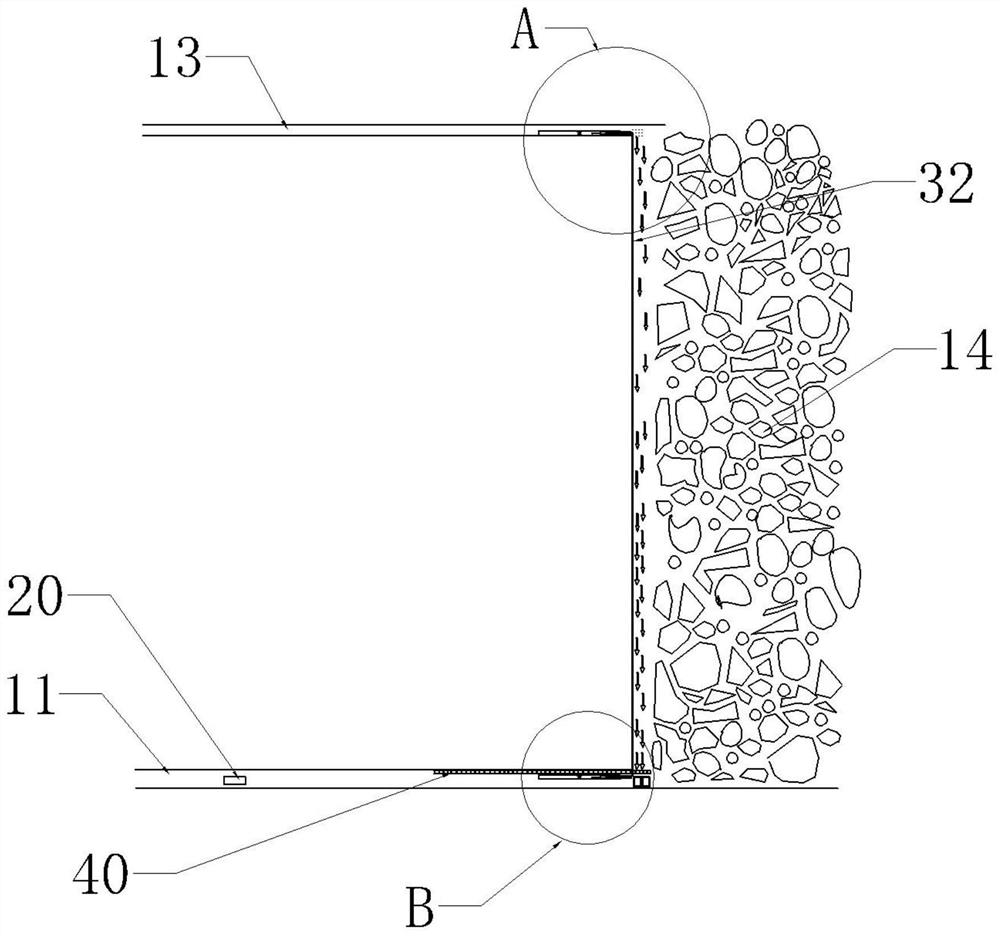

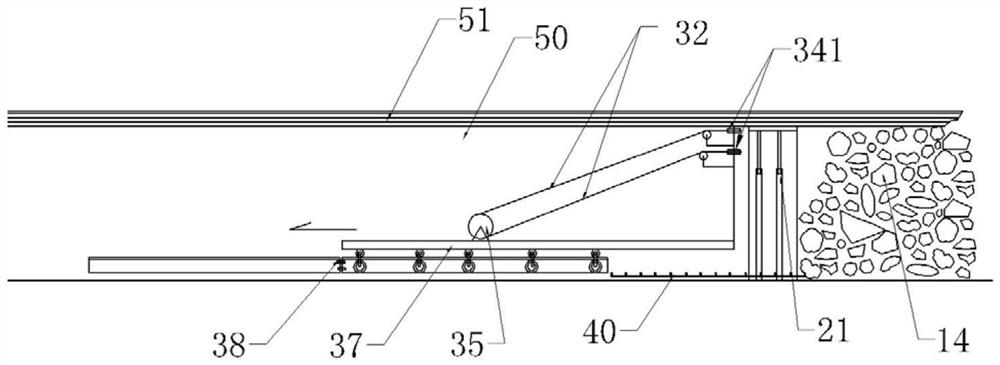

[0057]The reference signs in the accompanying drawings of the description include: working face transport lane 11, working face cutout 12, working face return air lane 13, goaf 14, hydraulic workstation 20, hydraulic support 21, hydraulic prop 22, diamond beaded rope host 30. Main engine track base 31, diamond beaded rope 32, diamond beaded rope supporting wheel 33, first guide wheel 341, second guide wheel 342, driving wheel 35, main engine walking base 37, heavy rail 38, scraper conveyor 40 , coal seam 50, coal seam roof 51.

[0058] The embodiment is basically as attached figure 1 - attached Figure 8 Shown:

[0059] A method of mining an extremely thin coal seam, comprising the following mining steps:

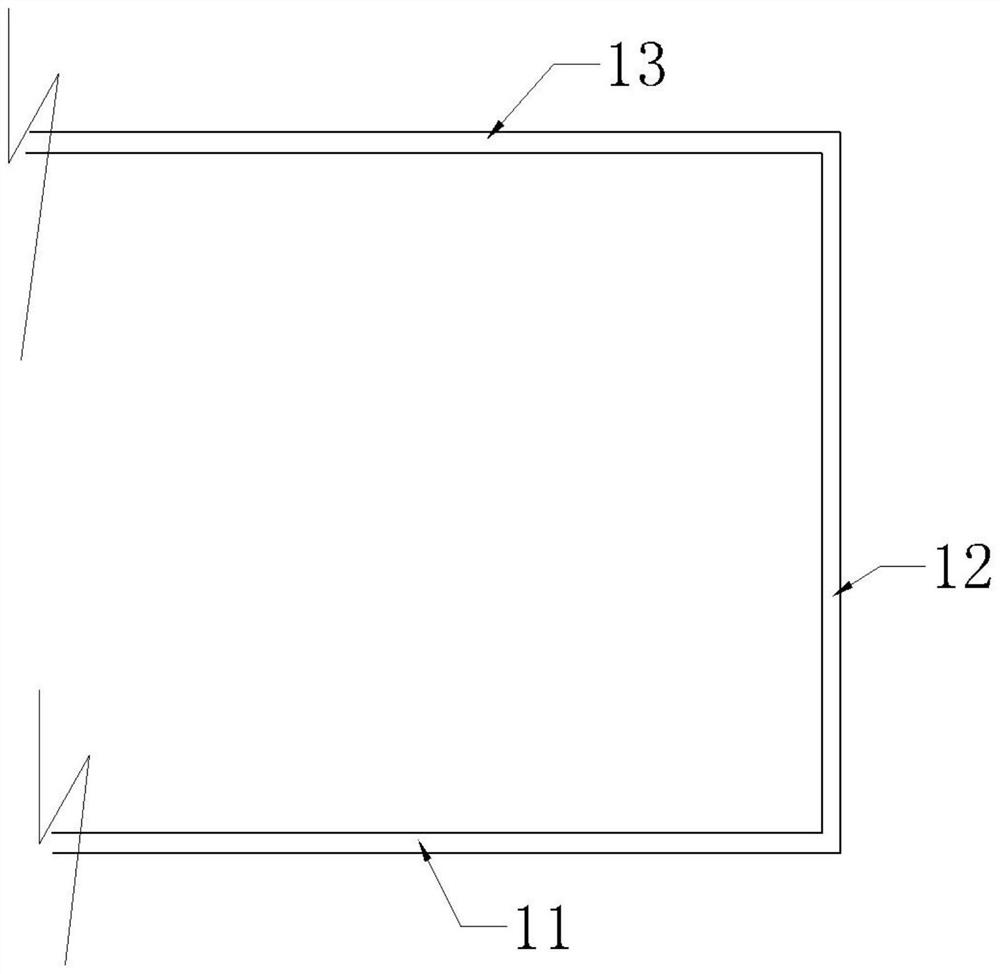

[0060] The first step is to arrange the longwall retreating coal mining face, such as figure 1 As shown, the working face includes the working face return airway 13, the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com