Underground interlayer type coal in-situ gasification mining system and construction method thereof

A coal, in-situ technology, applied in coal gasification, underground mining, mining fluids, etc., can solve the problems of poor gas tightness, unclear understanding of gasification chamber evolution law and main controlling factors, uneven heating of coal seams, etc. Enterprise economic benefits, realizing the value of coal resources, and the effect of maximizing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

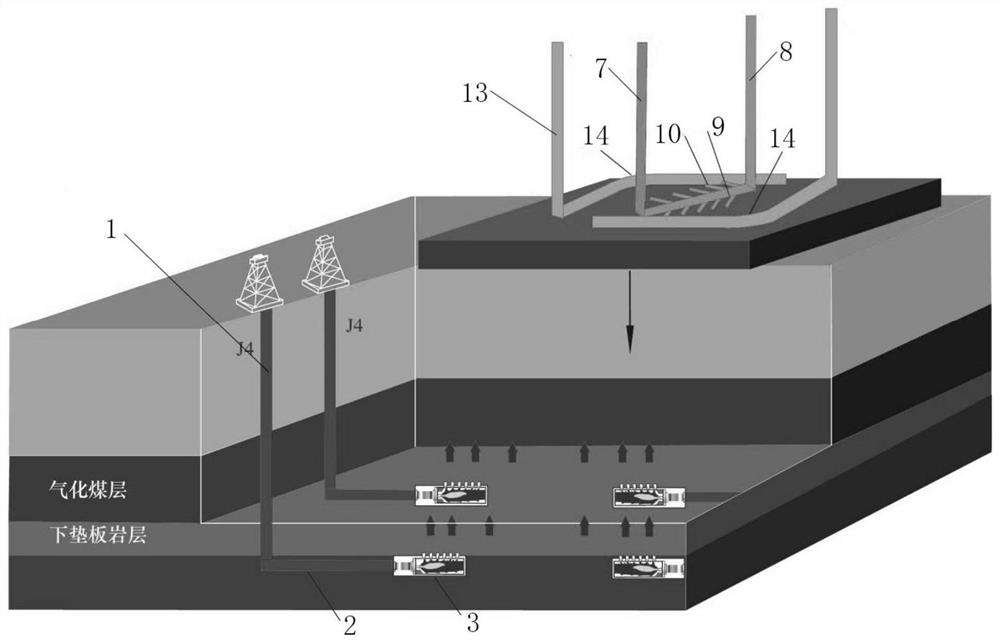

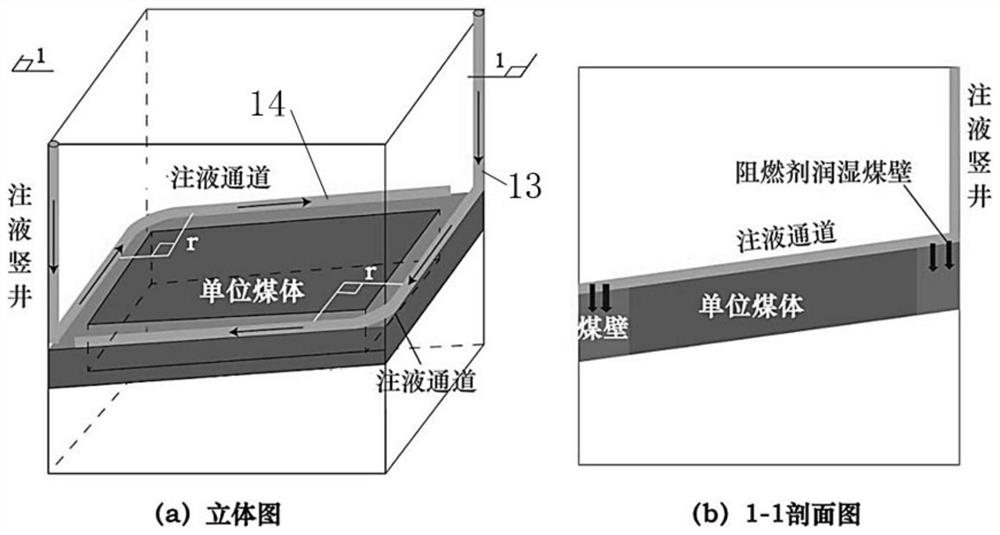

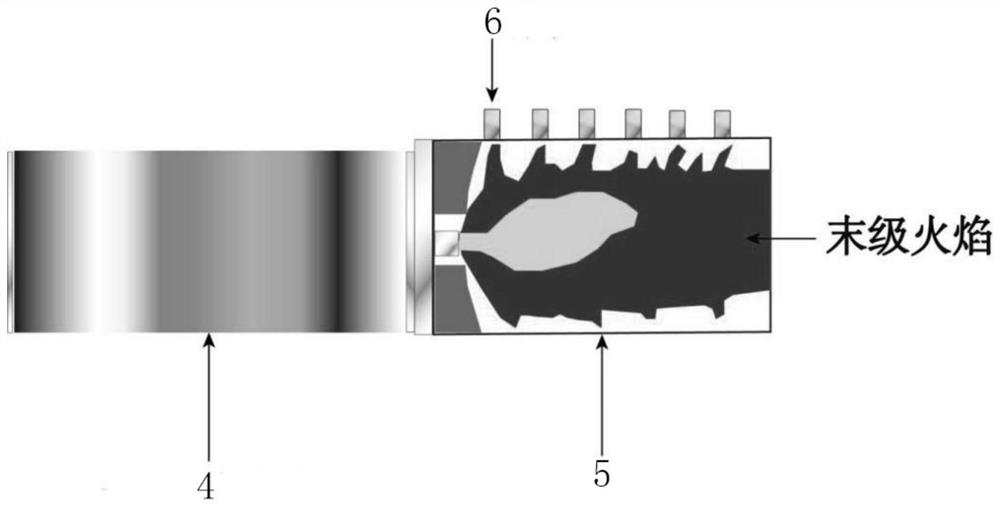

[0043] The invention is an underground interlayer type coal in-situ gasification mining system and its construction method. Under the background of the huge development potential of my country's underground coal gasification resources, the current UCG technology needs to focus on the direction to be overcome, and the western coal resources are green Guided by the advanced concept of mining, an attempt was made to propose an Underground Coal Interlayer In-situ Gasification System (UCIGS) and its construction method. The basic working principle of UCIGS is as follows: figure 1 As shown, a combustion device is installed at a certain depth in the rock layer below the coal seam floor (the underlying slate layer) to heat the underlying slate layer of the coal seam, and transfer heat to the coal seam through the underlying slate layer by utilizing the thermal conductivity of the underlying slate layer To gasify the coal seam to achieve the effect of interlayer heating, it should be no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com