Steel box girder overhaul hole structure convenient for overhauling

It is a technology that facilitates maintenance and steel box girder. It is applied to bridges, bridge parts, and bridge construction. It can solve problems such as difficulty in entering bridges for maintenance personnel or equipment, hidden dangers in operation and maintenance, and occupation of lanes under bridges, so as to ensure structural operation. Safety, simplify maintenance difficulty, reduce the effect of opening and closing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

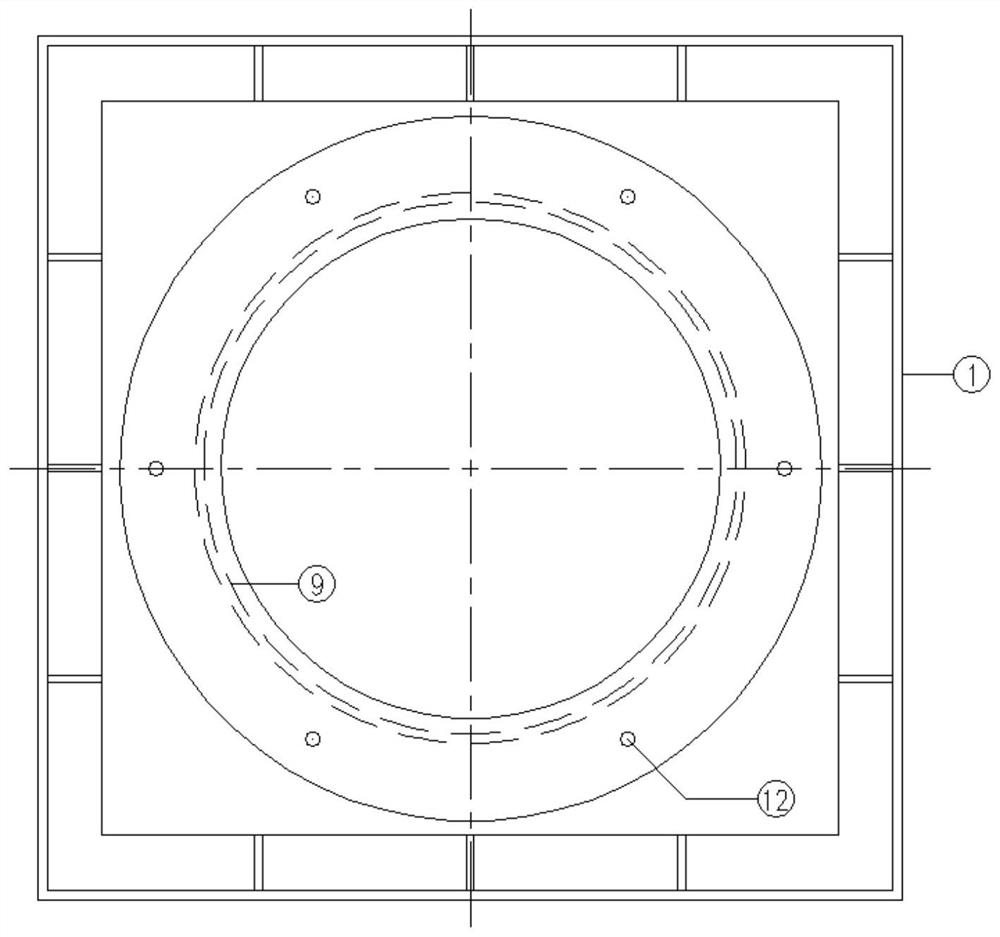

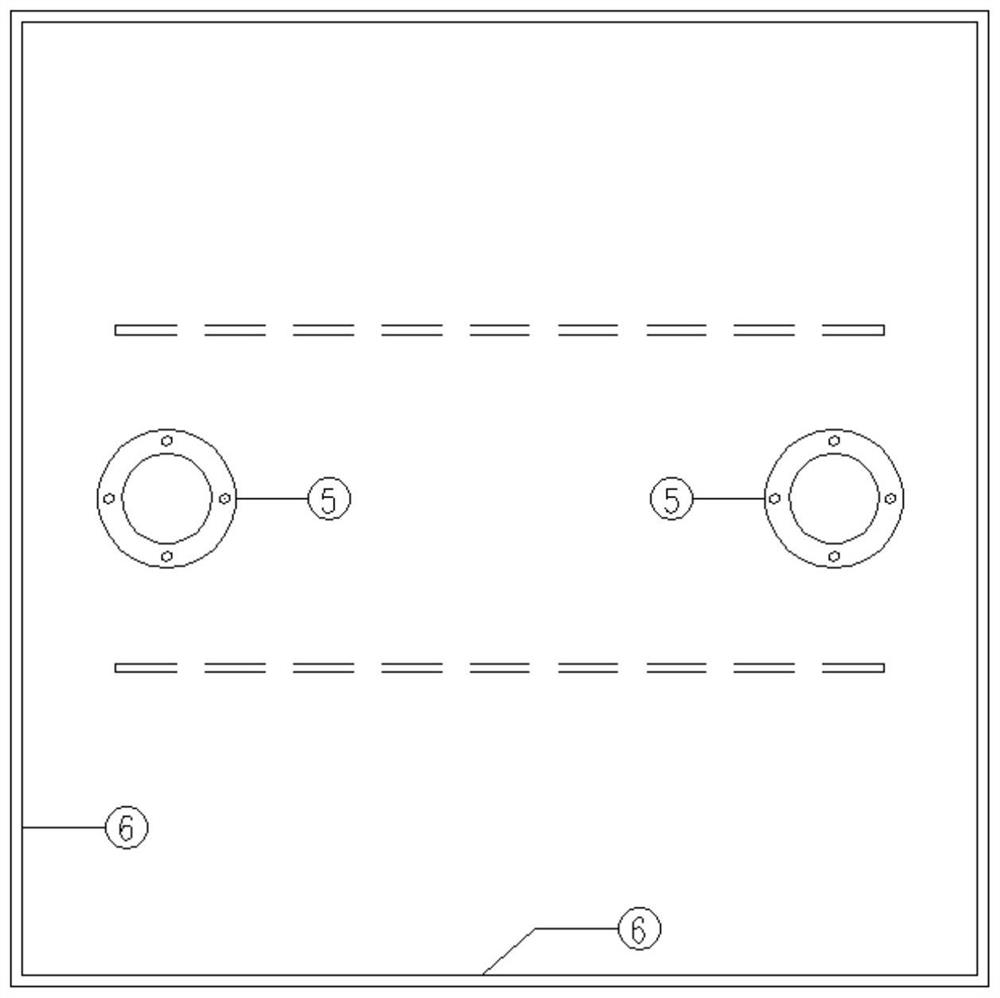

[0019] Concrete structure of the present invention sees figure 1 , figure 2 , image 3 shown. The double-layer maintenance wellhead design includes an outer rectangular wellhead device and an inner circular wellhead device. The double-layer wellheads are equipped with replaceable water-tight sealing devices to prevent the intrusion of dust and liquid, and greatly improve the guarantee rate of watertightness of the maintenance hole.

[0020] The outer wellhead device includes an outer rectangular wellhead (1), an outer rectangular maintenance manhole cover (2), a first waterproof rubber pad (3) is provided between the wellhead and the well cover, and a replaceable type waterstop kit(4). Among them, the water-stop kit is composed of extruded rubber belt and fillable and replaceable caulking water-stop liquid rubber base material, which can maintain good airtightness and waterproofness of the inspection hole under expansion, vibration and temperature changes.

[0021] The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com