A light motorized winching equipment

A motorized winch and equipment technology, applied in the direction of the spring mechanism, hoisting device, etc., to achieve the effect of small size, outstanding substantive characteristics, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

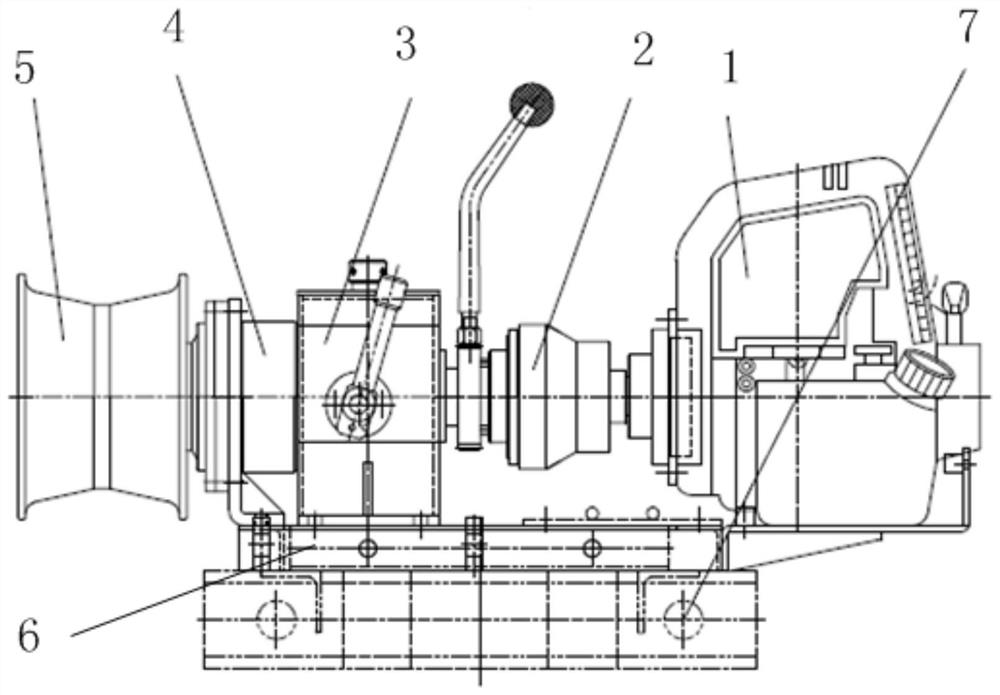

[0044] Such as figure 1 As shown, the present invention provides a light-duty motorized winching equipment, including a base 6, on which a gasoline engine 1, a clutch 2, a reduction box 3, a speed reducer 4 and a reel 5 are arranged, and the gasoline engine 1 is connected to the clutch 2 through a shaft coupling. connect;

[0045] The reduction box 3 includes an input shaft and an output shaft, and the reduction box 3 is connected with the clutch 2 through the input shaft 9, and connected with the speed reducer 4 through the output shaft 10;

[0046] The reducer 4 is connected with the reel 5 using a planetary gear structure; a light-weight gasoline engine 1 is used, and the gasoline engine 1 is connected to the reducer 3 through a coupling instead of a belt drive, which improves transmission efficiency and reduces power loss; the reducer 4 adopts a planetary Gear structure, compact structure, high transmission efficiency;

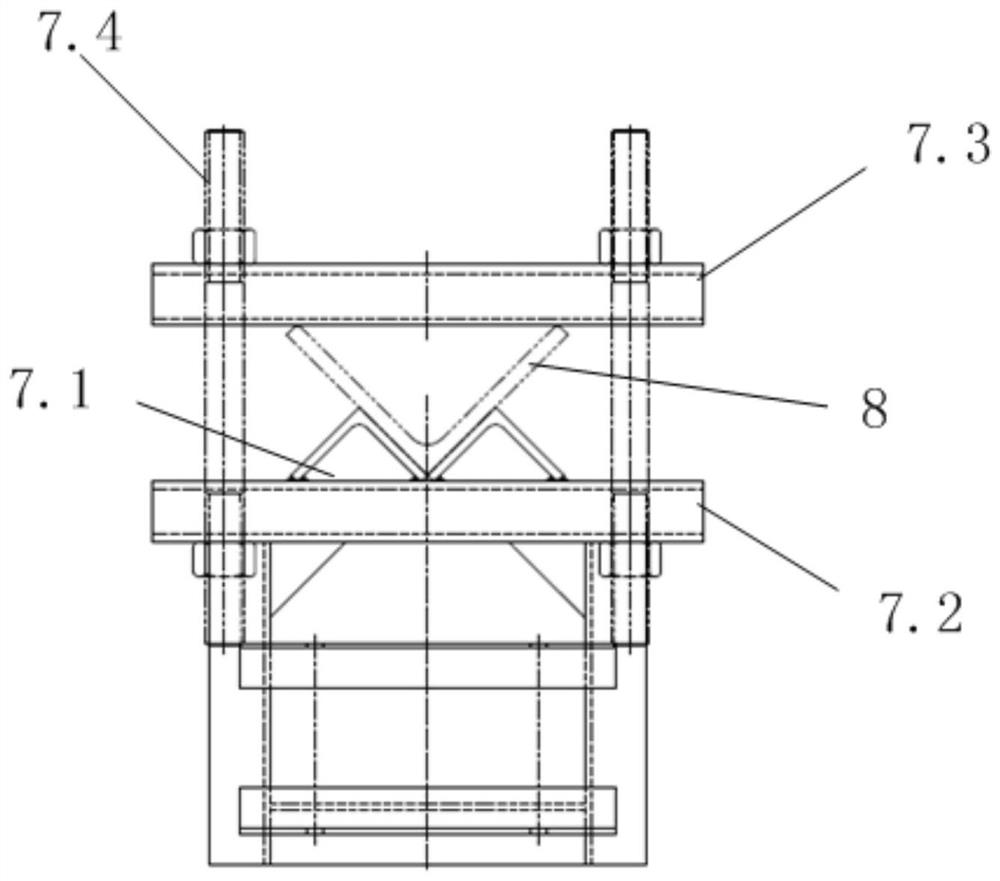

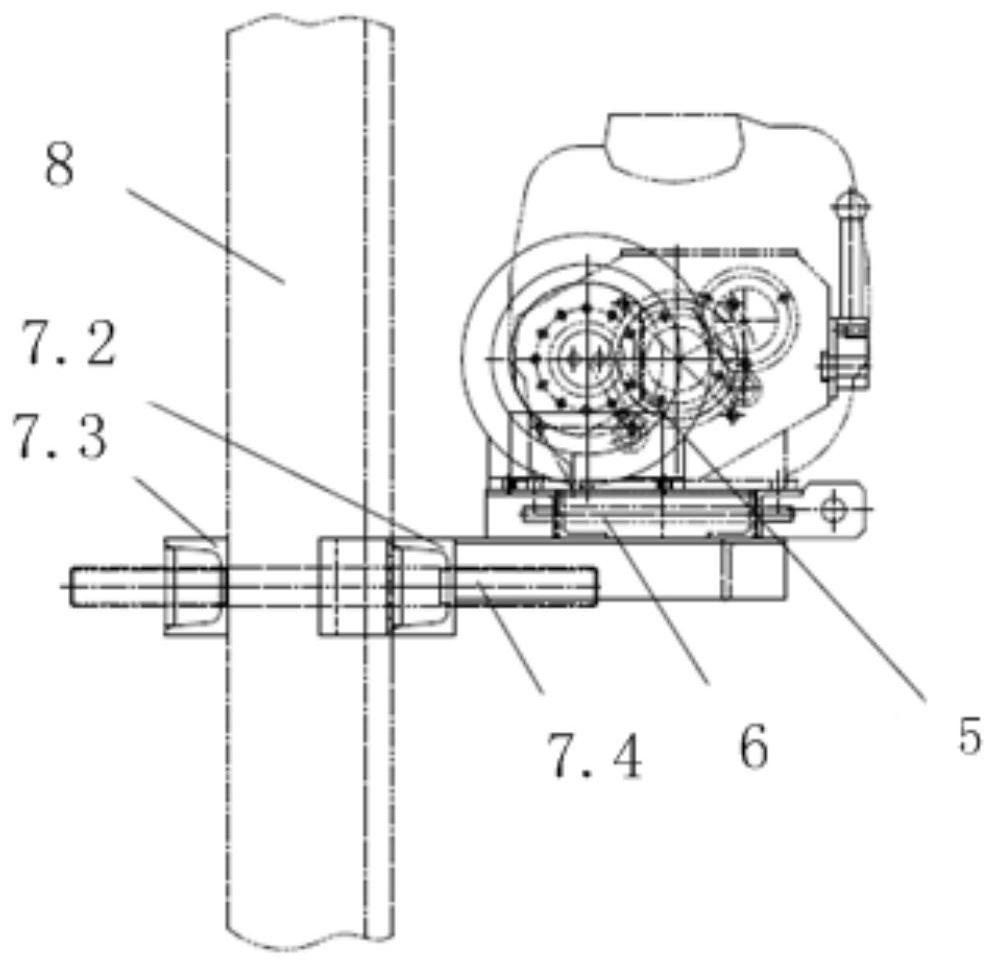

[0047] Such as figure 2 and image 3 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com