Linen thread pretreatment device for linen textile equipment

A technology of pretreatment device and textile equipment, applied in the direction of processing textile material equipment configuration, textile material processing, textile and papermaking, etc., can solve problems such as poor pretreatment effect, improve cleaning effect, save cost, and ensure the state of twine Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

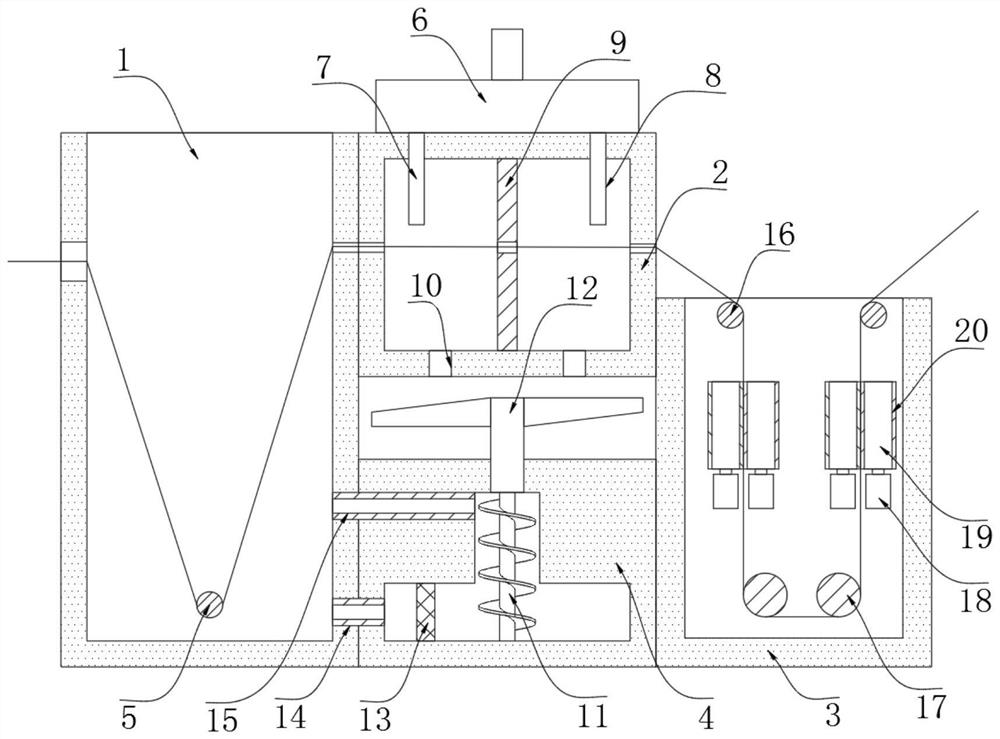

[0019] refer to Figure 1-2 , a hemp thread pretreatment device for hemp textile equipment, comprising a cleaning box 1, a drying box 2 and a lubricating box 3, the inner wall of the cleaning box 1 is rotatably connected with a cleaning roller 5, the top of the drying box 2 is fixed with a vortex tube 6, and the drying box The top of 2 is fixed with a cold air pipe 8 and a hot air pipe 7 respectively connected to the hot and cold air outlets of the vortex tube 6, and the inner wall of the drying box 2 is fixed with a partition plate 9, which divides the interior of the drying box 2 into hot and dry air. The dry part and the cooling part ensure the stable state after the treatment of the twine. The bottom of the drying box 2 is provided with two symmetrically arranged air outlets 10, and the inner wall of the lubricating box 3 is rotatably connected with two symmetrically arranged guide rollers 16 and two Lubricating roller 17, two sets of twisting mechanisms are arranged insid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap